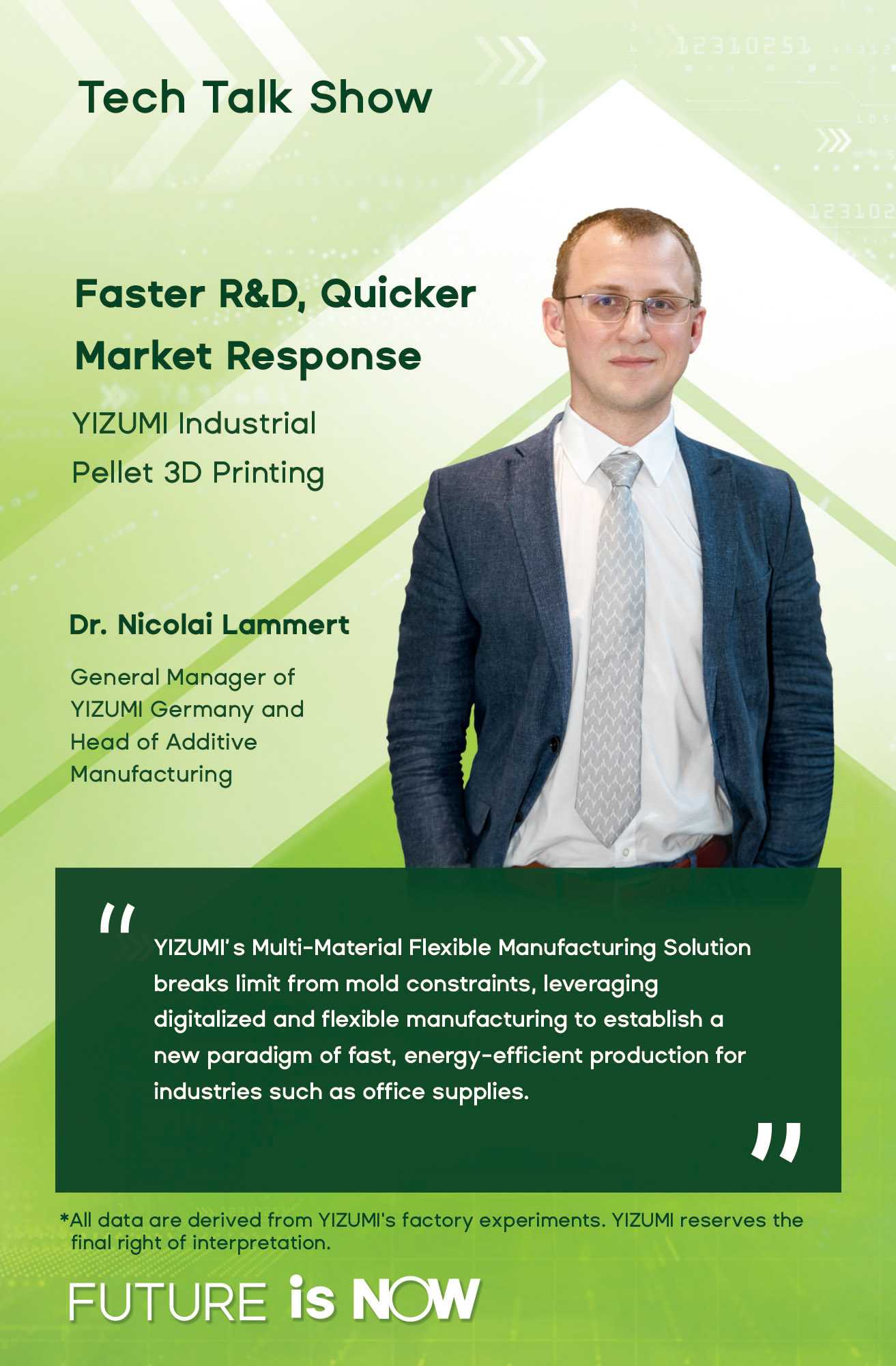

YIZUMI Multi-Component Solution: Mold-Free Smart Manufacturing

At K 2025, YIZUMI unveils Multi-Component Flexible Manufacturing Solution, addressing growing demand for customized and diversified products. Traditional mold-based processes are faced with long development cycle, high upfront costs, and material waste, making rapid adjustments and diverse production challenging. Additionally, runner, gate and other structures in traditional processes can lead to material waste, indicating space for improvement in resource utilization.

YIZUMI’s Multi-Component Flexible Manufacturing Solution breaks limit from mold, leveraging digitalized and flexible manufacturing to establish a new paradigm of fast, energy-efficient production for industries such as office supplies.

>>Core Technology?01

「Compact High-Efficiency Structure」

- With a footprint of only 1800×1700×2300 mm, it enables a single machine to print components equivalent to the thousand-ton class injection molding machines.

「Fully Integrated Intelligent System」

- The modular integration of feeding, temperature control and molding units requires no external accessories, enabling plug-and-play deployment for industrial use.

「Rapid Production Readiness」

- Equipment commissioning and parameter calibration can be completed within 15 minutes, supporting rapid response to urgent orders.

「Open Material Ecosystem」

- Compatible with both injection- and extrusion- grade granulates, it can smoothly connect with existing material supply chains.

「Innovative Mold-Free Technology」

- The technology achieves mold-free, lowering storage and maintenance cost.

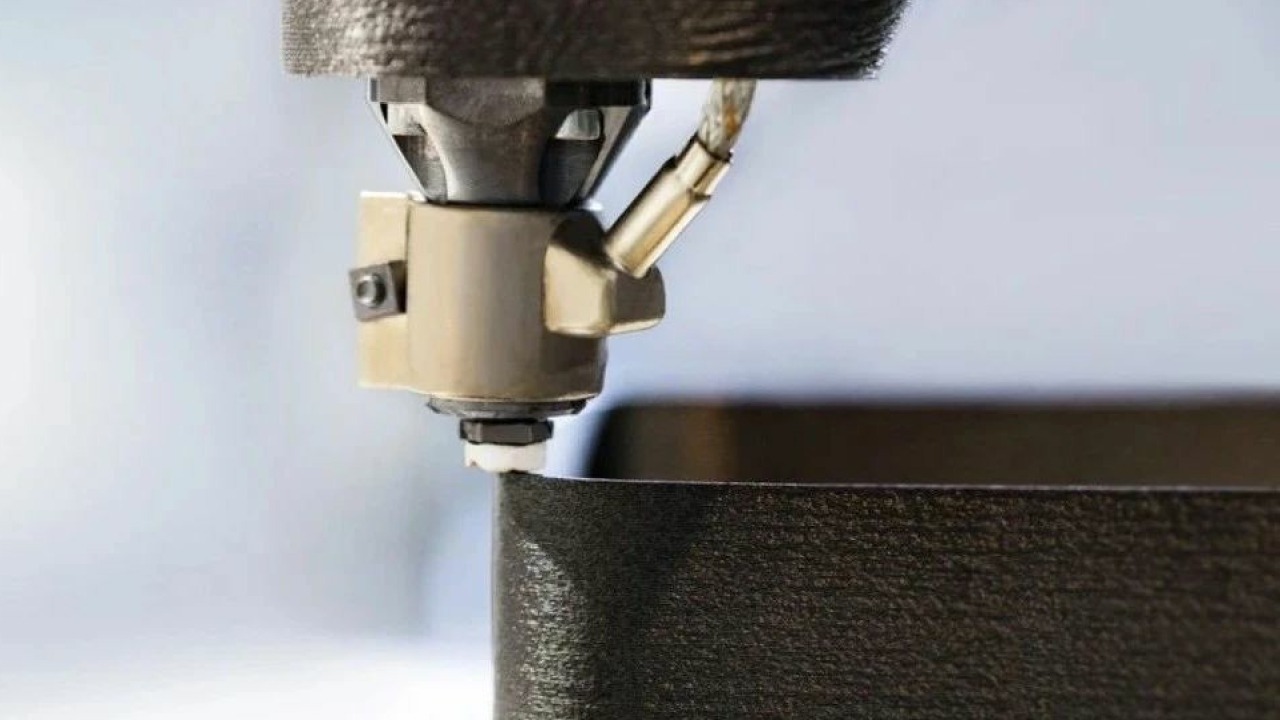

「Intelligent Robotic Arm Design」

- The machine integrates 6-axis robotic arm system, breaking geometric limitations of traditional processes.

「Fully Automated Production Solution」

- Standardized interfaces supports automated expansion, building a 24/7 unmanned intelligent production line.

「Innovative Technology Core」

- SpaceA's patented compact screw extruder allows for fast and efficient printing.

>>Customer Value 02

「Operation Value」

- Enables small-batch, multi-variety flexible production and shortens R&D cycles for new products.

- Speeds up order response, reduces prototyping costs, and accelerates ROI.

- Cuts mold storage costs, improving operational efficiency.

「Production Value」

- Supports fiber-reinforced materials, engineering plastics, and multi-material composite manufacturing.

- Achieves "zero molds, zero waste, and zero delays" in intelligent composite manufacturing.

- Enhances production flexibility and ensures stable product quality.

「Market Value」

- Addresses low-carbon policy and reduces carbon tariff risks.

- Rapidly adapts to diverse, small-batch market demands.

- Enhances product innovation flexibility and competitive edge.

With growing demand for customized and diversified products, manufacturers increasingly require more flexible and highly responsive production. YIZUMI Multi-Component Flexible Manufacturing Solution overcomes traditional limits, enabling composite production with fiber-reinforced composites and engineering plastics to meet complex structural and performance requirements. Digital parameter configuration allows rapid product changeovers and flexible small-batch and multi-variety production, and shorter development cycles. High material utilization supports sustainable, circular manufacturing.

* All data are derived from YIZUMI's factory experiments.

Please refer to the customized equipment for product data.