YIZUMI's RHEO Sparks Innovation in the Rheocasting Revolution

Abstract:

Explore how YIZUMI's RHEO series advances semi-solid molding with dedicated aluminum rheocasting machines, transforming die casting with precision and efficiency.

In an era where manufacturing is continually pursuing innovation and efficiency, YIZUMI proudly unveils the RHEO series, a dedicated Al Rheocasting machine, based on its profound technological foundation and incisive market insight.

The release of RHEO not only underscores YIZUMI's exceptional expertise in semi-solid molding technology, but also reflects its strategic dual drivers in magnesium and aluminum alloys. This innovation provides the die casting industry a new boost, propelling it to new heights.

01.「Unlocking the Process」

Discovering the Secrets and Core Technologies

Semi-solid molding technology, born in the 1970s at MIT, USA, has shown remarkable potential since its debut. While it shares similarities to traditional die casting and forging, it also offers distinct advantages.

In traditional die casting technology, molten metal is forced into molds under high pressure before cooling to form the final shape. This process often causes defects such as porosity and shrinkage. Casting process mainly forge casting deforms when it is in state of solid or high-temperature solid metal under pressure, resulting in superior mechanical properties but limiting part complexity.

In contrast, semi-solid molding technology processes materials in a mixed solid-liquid state. It employs low-speed injection to enable laminar filling of molten aluminum, minimizing turbulence-induced air entrapment, followed by a high-pressure holding phase that ensures superior shrinkage compensation for the parts.

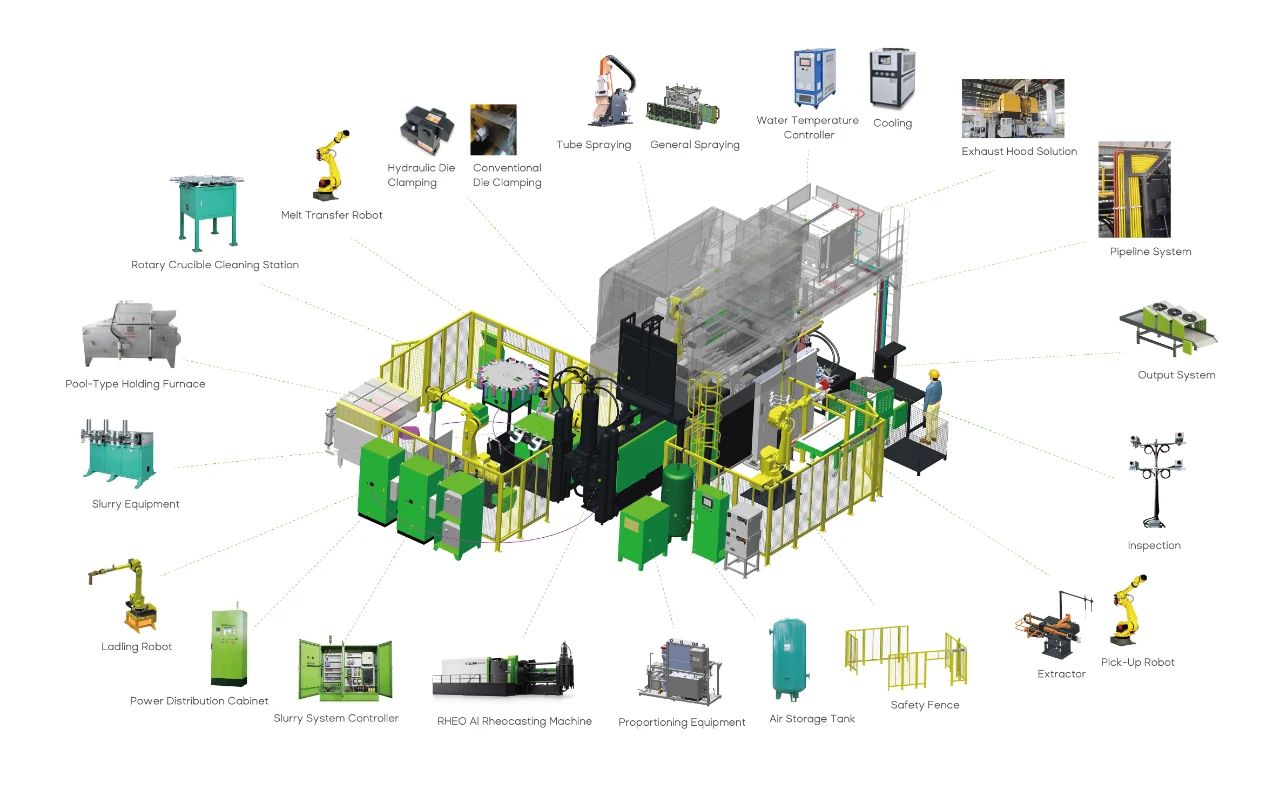

The semi-solid process involves smelting, preparing semi-solid slurry, low-speed filling, pressure holding, cooling, and demolding, all requiring specialized molding equipment. Furthermore, the production line needs to include slurry preparation unit capable of precisely controlling the temperature and shearing of the aluminum slurry to ensure slurry quality and process stability.

02.「Breaking Barriers」

Overcoming Technical Challenges to Forge Innovative Tools

Despite its vast potential, semi-solid molding technology has faced numerous challenges over the past four decades, particularly a lack of high-performance, cost-effective dedicated equipment. Traditional die casting machines struggle to fulfill market demands. YIZUMI keenly recognized this opportunity and committed to bridging it.

However, the R&D journey is full of challenges and obstacles. Using traditional die casting machines for semi-solid processing presents several challenges: precise parameter control is difficult, resulting in unstable production; inconsistent slurry uniformity leads to uneven product quality; frequent product defects increase manufacturing costs and scrap rates; and insufficient equipment stability reduces production efficiency and continuity.

YIZUMI's R&D team tackled these challenges head on, conducting extensive data validation and detailed process parameter analysis to identify the root causes. They worked across hydraulic, software engineering, and semi-solid research teams to systematically improve every link of the man-machine-material-method-environment mode. After countless trials and refinements, the team successfully developed the RHEO series Al Rheocasting machines, breaking technological barriers and closing a market gap.

03.「Showing Strengths」

Empowering Industry Transformation with Advanced Technology

Having mastered the precise application of semi-solid molding technology, the RHEO series integrates YIZUMI's multiple core technologies to deliver exceptional performance, cementing the company's leadership in the global semi-solid molding market.

Built on YIZUMI's Sino-European technology platform, the RHEO series blends advanced European innovation with China's cost-effective supply chain, significantly reducing production costs and boosting the competitiveness of semi-solid molding processes.

Key features include:

1. The Rheocast injection unit, custom-designed for Al Rheocasting, offers powerful dynamic injection force and fully closed-loop real-time control, with a system pressure of up to 21 MPa.

2. Ten-stage precision control during low-speed injection ensures accurate casting pressure and dimensions.

3. Intelligent operation and data management simplify workflows and increase productivity.

4. Servo energy-saving technology greatly reduces power consumption, extends mold life by over 30%, and significantly shortens production cycles, matching green manufacturing trends.

RHEO has made a key advancement in rheocasting by integrating these core advantages. According to Mr. Wang Caihua, Casting and Mold Technology expert and Semi-Solid Aluminum Alloy Product Manager of YIZUMI Die Casting Machine Division, RHEO's cutting-edge rheocasting technology allows aluminum alloys to be cast in the liquid + solid stage. This technology results in a unique microstructure where the liquid phase envelops the spherical solid phase, greatly reducing shrinkage defects during solidification. As a result, RHEO produces complex-shaped, dimensionally precise castings with excellent mechanical properties, superior thermal conductivity, high surface finish, and high density, as well as compatibility with heat treatment and welding, leading to significantly improved product quality.

04.「Leading Applications」

Starting a New Journey with Diverse Industry Expansions

The true value of technology is demonstrated by its impact in the real world. In today's era of intelligent, green, and high-end manufacturing transformation, semi-solid molding technology is a pivotal driver of industrial upgrade.

The RHEO series marks a breakthrough by providing turnkey production solutions that are efficient, precise, and energy-saving. It empowers enterprises to overcome traditional production bottlenecks, driving high-quality industrial transformation and growth.

The RHEO series is planned to cover a range of 530 to 2,500 tons, catering to the production needs of enterprises of all sizes. Its target markets include high-demand sectors, such as new energy vehicles, communications, cycling, and transportation, all of which require excellent product quality and performance.

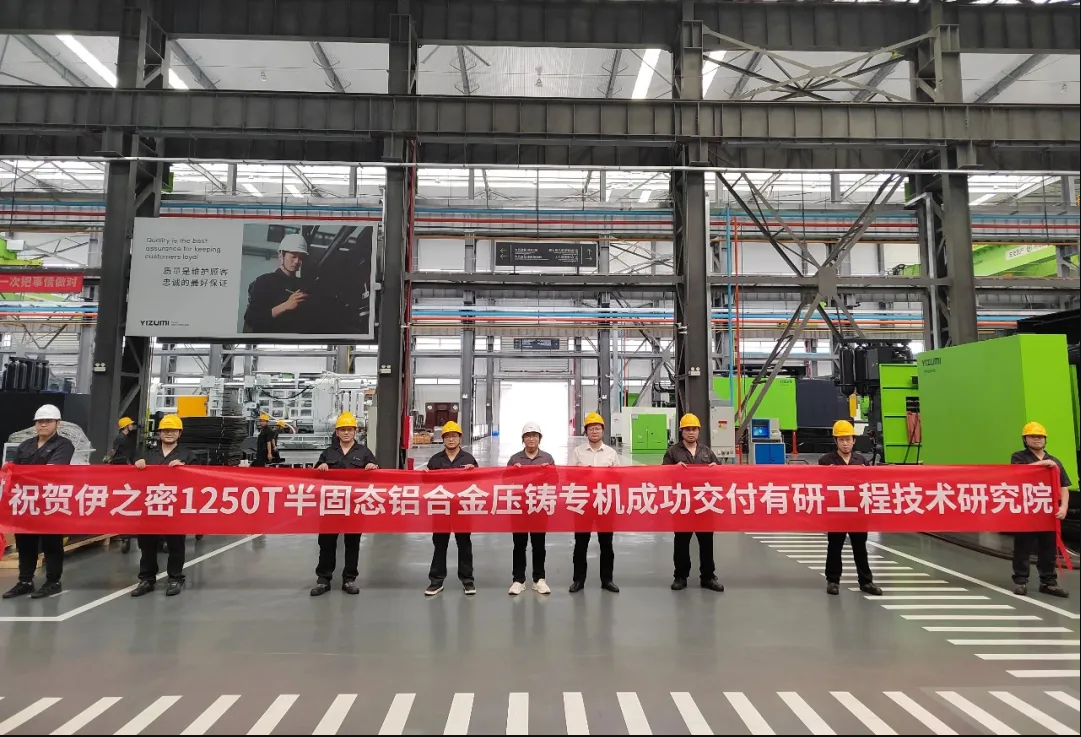

In April 2025, YIZUMI successfully delivered a RHEO1250 machine to GRIMAT Engineering Institute Co., Ltd., marking a milestone in the collaboration between a leading research institution and a domestic high-end equipment manufacturer. This step signifies a major advance in the industrialized application of rheocasting and highlights YIZUMI's capability to provide turnkey solutions—from slurry preparation to finished products—to customers in a seamless one-stop service.

Looking ahead, RHEO will uphold its spirit of "Recasting Alloy with Innovative RHEO Intelligence", continuously pushing technological innovation to power the industry's growth, and lead semi-solid molding technology to new heights.