New application of digital technology in the molding manufacturing

Digitalization has become a global trend due to its development and application in various industries.

Digital technology is increasingly helping to solve complicated challenges in the real world. Mr. Zhang Yanfei, Chief Software Architect of Global Innovation Center of Yizumi Holdings Co., Ltd. (YIZUMI), shares "Innovative Digital Technology Application in Molding Manufacturing" with four application scenarios, including intelligent control technology, equipment predictive maintenance, process intelligent optimization, and manufacturing operation management.

To begin, AI algorithms comprehensively empower sensor technology, servo control technology, and Internet of Things communication technology, especially in the field of intelligent control technology such as molds, temperature, oil temperature, automatic molds, and flow control, assisting in the upgrading and intelligentization of equipment.

Smart locking force, for example, has been partially regulated on some models, altering the prior linear and single control technology. Manufacturers can benefit from the use of online optimization algorithms and real-time balance detection technology for locking force, including reduced equipment and mold damage, extended machine lifespan. In addition, smart locking force management helps reduce equipment energy consumption.

Next, the core of equipment predictive maintenance is tracking the trend of key equipment performance parameters and setting up a mathematical model of performance parameter trends and equipment failures to evaluate the health status of equipment, including lifespan prediction and remaining life evaluation of key components, and predictive maintenance recommendations for equipment, achieving equipment health management.

In the monitoring of hydraulic oil in equipment, for example, the equipment wear state and degree can be predicted by monitoring the moisture and impurities in the oil, allowing us to determine the ideal oil change time. It also allows us to predict the key component lifespan of molding equipment, like screws in the injection molding machines.

Furthermore, we could use some assistive technologies like remote collaboration and virtual reality to improve the effectiveness of equipment operation and maintenance. When a machine fails, the equipment operators can contact our customer service center via the remote assistance function. With advanced AR technology and spatial static markers of AR, our experts and operators may collaborate to execute component maintenance and resolve equipment failures, achieving remote diagnosis and collaboration.

Then, moving on to process intelligent optimization, there are different technologies like digital technology-based process simulation technology, online quality diagnosis and self-optimized parameter control technology, and process adjusting assistants. People frequently associate this topic with massive data. However, it is not always necessary in practice. We could employ priori process knowledge to narrow down the problems and achieve good application results on small sample datasets.

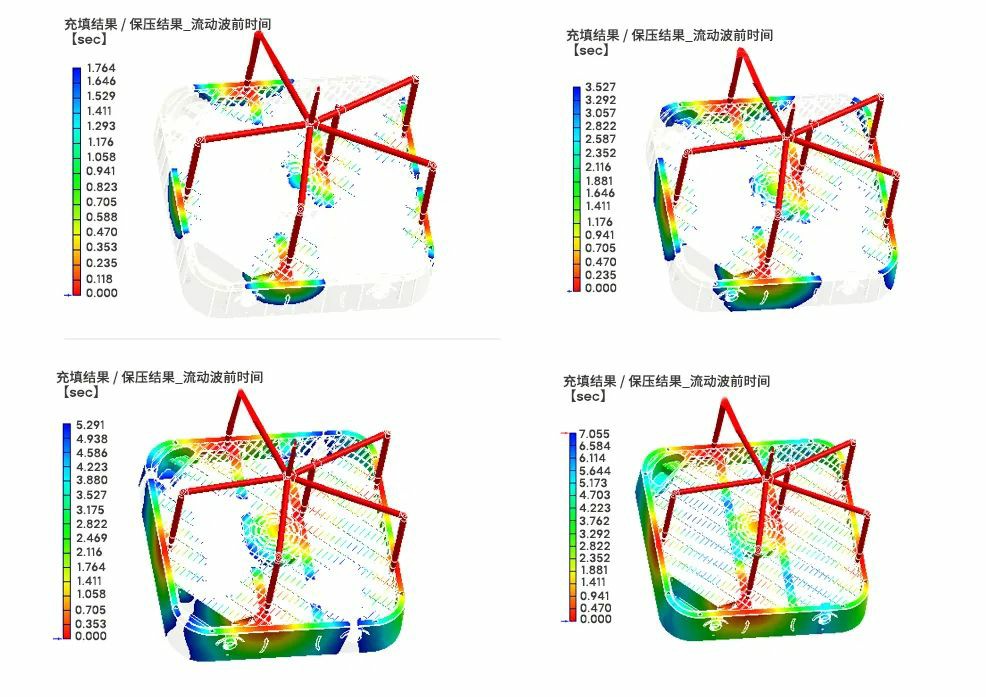

For example, the design and manufacture of integrated die casting parts has become more complex and difficult in recent years. In the absence of sufficient experimental data, CAE simulation-based priori knowledge has irreplaceable advantages.

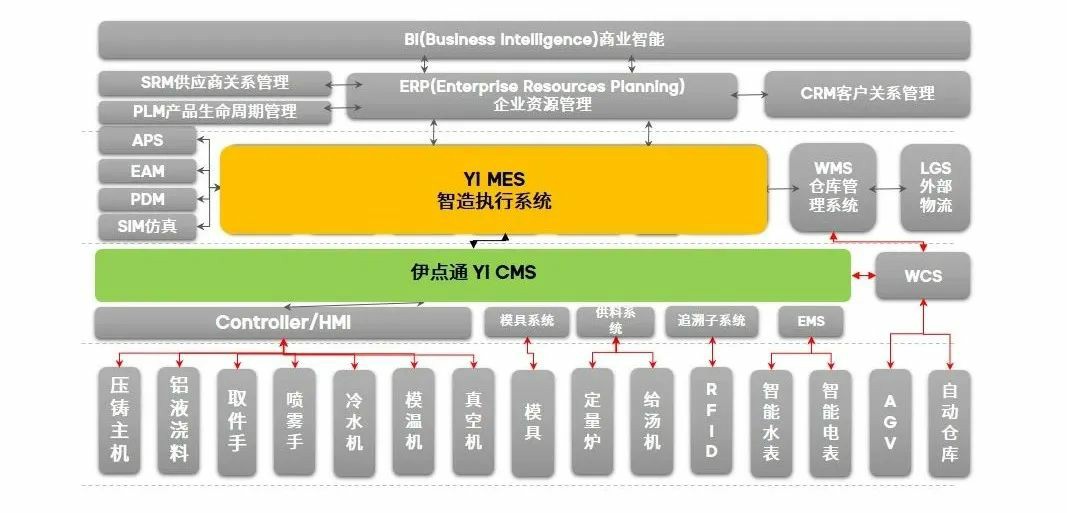

At last, let us focus on manufacturing operation management. We have discussed intelligent control technology, equipment predictive maintenance and process intelligent optimization, which are all the segments of intelligent manufacturing technology. However, they all require a digital system to fulfill the transformation and achieve a new business management-decision-operation mode by integrating intelligent systems and digital process tools. On this basis, with MES as the fundament, we horizontally integrate PLM, APS, WMS, EAM, etc. and vertically connect IT and OT to informationize manufacturing businesses and empower digital and intelligent operation.

The digitalization and intelligence of manufacturing operations should primarily focus market and order forecast, and delivery time forecast within the restrictions of existing production factors. These two forecasts are based on the digitization and informatization of manufacturing operations, which may accurately depict the value of digitization.

In sum, digitization has combined automatic and intelligent operations and remote collaboration and virtual reality technology to realize flexible manpower or even unmanned operations. Compared with informatization, digitalization holds employees to a higher standard. It requires companies to improve their business models with digital technologies, and integrate digital technologies into every business process, including marketing, R&D, manufacturing, management, and decision-making, radically changing how businesses run and providing value to customers.