YIZUMI Thixomolding Machines: Empowering EV Industry Growth

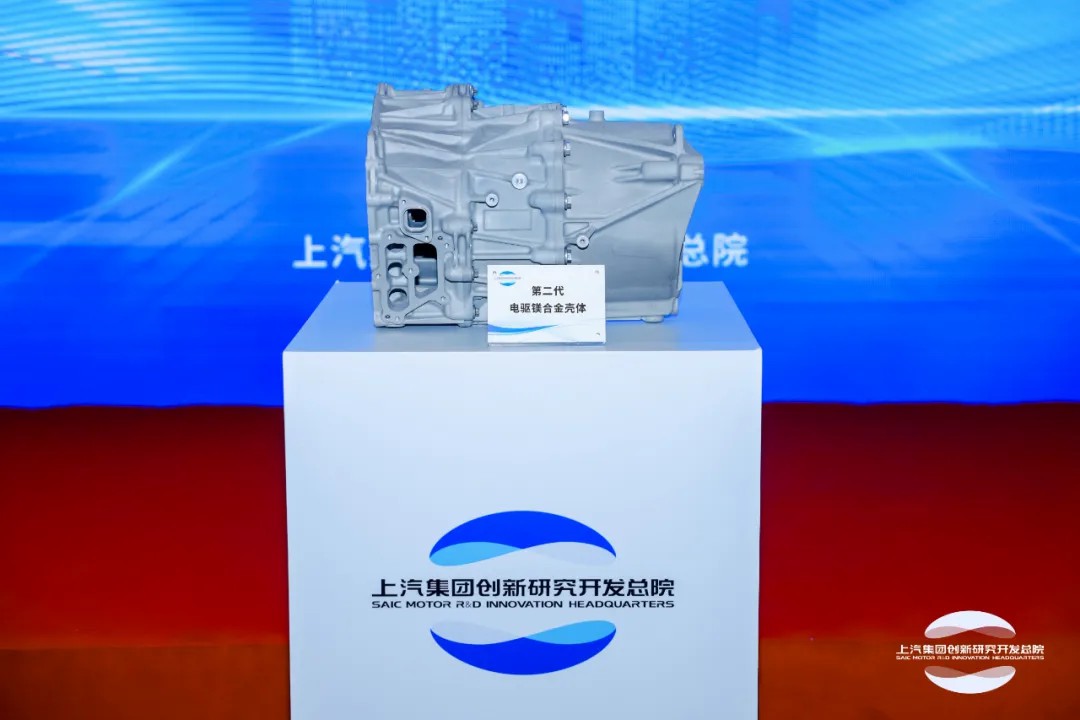

On November 29, SAIC Motor launched its second-generation magnesium alloy electric drive housing and a streamlined three-in-one electric drive system, a significant step forward in the lightweighting of electric vehicles.

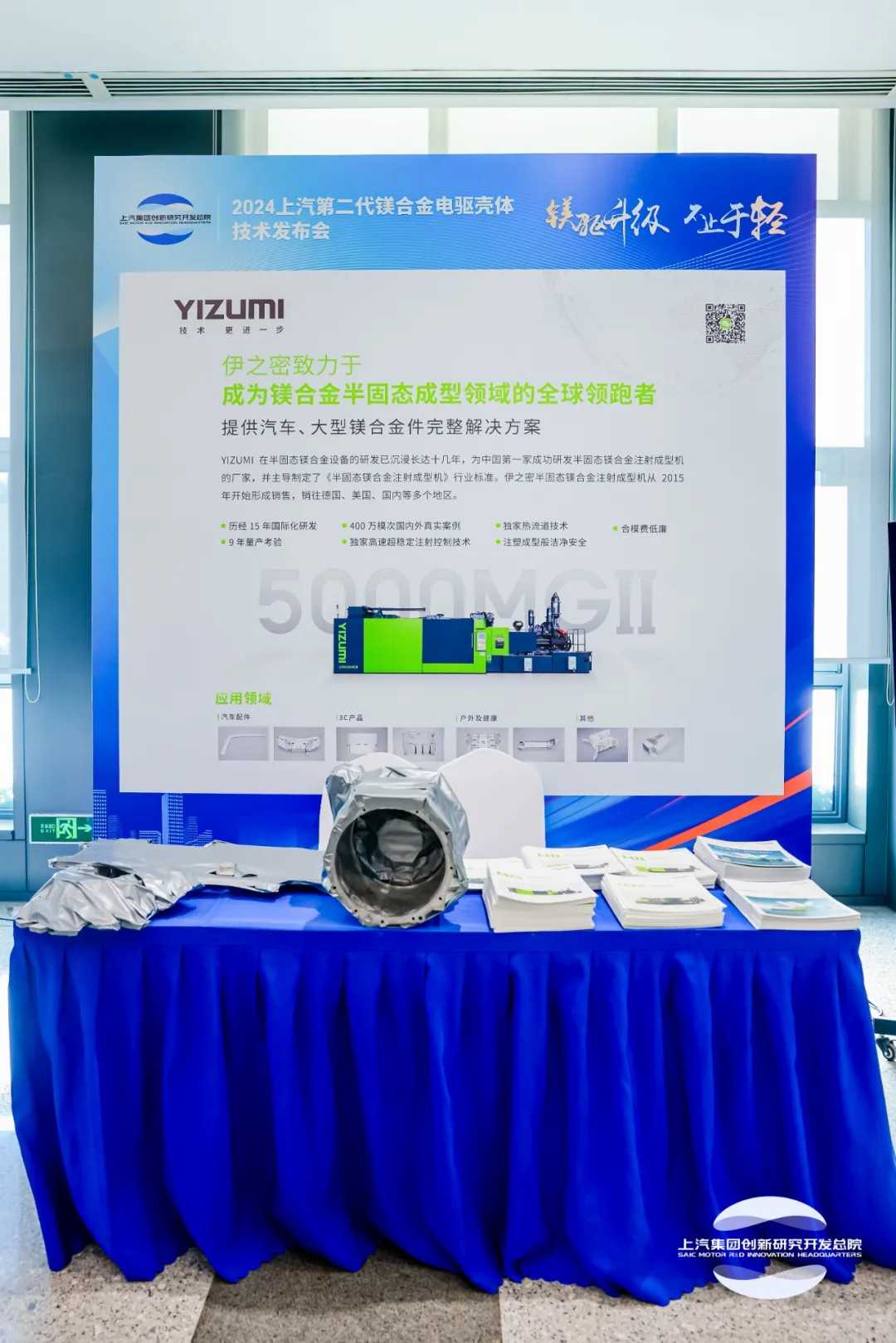

YIZUMI's 3200T and 2000T Thixomolding machines, which lead the globe in critical specs like locking force, injection capacity, and melting & feeding capacity, are perfectly suited for producing SAIC's second-generation magnesium alloy electric drive housings. These machines are set to be pivotal in the mass production process and were featured in a presentation on Thixomolding Technology for Magnesium Alloy Automotive Parts at the tech launch event.

In 2024, the scale of new energy vehicles (NEVs) in China is expected to exceed 10 million units, with projections reaching 20 million units by 2030. Each NEV requires at least one drive motor. Currently, the average weight of an aluminum alloy motor housing is 20 kilograms. Switching to magnesium alloy housings could reduce the weight by one-third, significantly increase motor power density, and theoretically reduce costs by 40%.

Currently, this offers carmakers a cost-effective solution. With the dual advantages of cost savings and weight reduction, magnesium alloy motor housings are poised to become standard for automakers, potentially creating a 200,000-ton industry for these components.

As a Thixomolding pioneer since 2009, YIZUMI has reached an international advanced level with its Thixomolding machines, boasting extensive industry experience and a record 4 million mold cycles for domestic Thixomolding equipment. With this track record, YIZUMI is set to play a leading role in supplying advanced Thixomolding equipment for the emerging 200,000-ton magnesium alloy motor housing industry.

SAIC Motor's first-generation magnesium alloy electric drive system was applied in the IM L7 in 2022. Compared to traditional aluminum alloy materials, this system achieved a weight reduction of 7 kg. With its superior performance, the power density of the entire electric drive assembly reached an impressive 4.4 kW/kg. This marked the world's first application of magnesium alloy in mass-produced electric drive products and became the largest magnesium alloy component in the automotive sector at the time. Its outstanding lightweight performance contributed to the strong market performance of IM, RISING, and MG models. It also won the "2024 Outstanding Magnesium Automotive Casting Award" from the International Magnesium Association. However, the sealing and safety performance of traditional high-pressure die casting equipment used in the first generation of magnesium alloy electric drive systems still fall short of perfectly addressing the risks of oxidation and combustion under high temperature and high pressure during magnesium alloy molding, as well as the requirements for rapid filling. To fundamentally resolve these technical challenges, SAIC Group has taken an interest in the Thixomolding technology supported by YIZUMI Thixomolding machine, which is owned by Ningbo Sinyuan ZM

Thixomolding technology manages metal solidification to create a uniform, fine, spherical primary phase. The resulting slurry flows well under pressure, preventing cracks and deformation, and enhancing the quality of the final product. It also cuts energy use by doing away with melting furnaces and protective gases. Additionally, it provides better strength, ductility, and corrosion resistance compared to conventional die casting.

SAIC Motor has combined Thixomolding with high-pressure die casting, fully integrating the advantages of both processes. Its second-generation magnesium alloy casing demonstrates superior mechanical properties, enhanced corrosion resistance, and higher densification. Moreover, the production process eliminates the need for protective gases, significantly reducing energy consumption. This is a breakthrough technology that offers both high performance and environmental benefits.

The Yizumi 3200T and 2000T Thixomolding machines have enhanced three key parameters—clamping force, injection capability, and melting and feeding capacity—to reach a globally leading level. These advancements align perfectly with the manufacturing process requirements for the second-generation magnesium alloy drive motor housings.

YIZUMI's 3200T and 2000T Thixomolding machines, engineered for SAIC Motor's groundbreaking Thixomolding magnesium alloy motor housing, offer injection pressures up to 100 MPa, adeptly tackling shrinkage issues in large-scale component manufacturing. Equipped with high-flow, fast-responding hydraulics, these machines ensure robust filling performance. With a 160 mm screw and a stable output exceeding 11 kg, they lead in injection capacity, melting & feeding capacity, and clamping force, striking a balance between internal efficiency and external performance. This reflects YIZUMI's dedication to innovation and its mission to use technology for positive impact. By integrating European technology, internal R&D, and multiple advanced technologies, YIZUMI has secured numerous key patents and fine-tuned its equipment to meet customer needs. This has improved operability, reduced maintenance, lowered energy use, enhanced safety, and minimized lifecycle costs, poised to expedite the adoption of lightweight magnesium alloys in new energy vehicles.

Innovation has always been YIZUMI’s core principle. The motto "Think Tech Forward" reflects its unrelenting pursuit, and "Customer Value Enhancement" serves as our guiding action principle. The successful debut of SAIC Motor’s mass-produced Thixomolding magnesium alloy motor housing is the best interpretation of this principle., YIZUMI’s Thixomolding machines have empowered numerous high-end domestic and international clients, establishing long-term partnerships.

Looking ahead, YIZUMI will continue exploring new applications for magnesium alloy with its customers, deepening its focus on research and innovation, consolidating its leadership position, driving innovation across the magnesium alloy industry chain, and contributing to the 10-billion-yuan-scale application of magnesium in new energy vehicles.

*The data above were acquired by testing in the factory, only for your reference. As to the specific data, please refer to the actual equipment.