Die Casting: A Comprehensive Guide to Process, Machines, and Applications

Abstract:

Discover the fundamentals of die casting, essential machines, and key applications. Learn how YIZUMI die casting machines, including the HII-S Series, deliver precision, efficiency, and reliability for high-performance manufacturing.

Die casting is a highly efficient and precise metal casting process widely used in manufacturing industries. It enables the mass production of complex metal parts with excellent surface finishes and dimensional accuracy. As the demand for high-quality die casting grows, selecting the right die casting machine becomes crucial for achieving optimal results.

At YIZUMI, we specialize in providing state-of-the-art die casting solutions tailored to global markets. Our HII-S Series High-end Cold Chamber Die Casting Machine (1000-5000T)?is designed to meet the evolving demands of modern manufacturing. With precision, efficiency, and reliability at its core, our integrated die casting solutions help manufacturers enhance productivity while reducing operational costs.

In this guide, we explore the die casting process, essential machines, key applications, and why YIZUMI die casting machines?stand out in the industry.

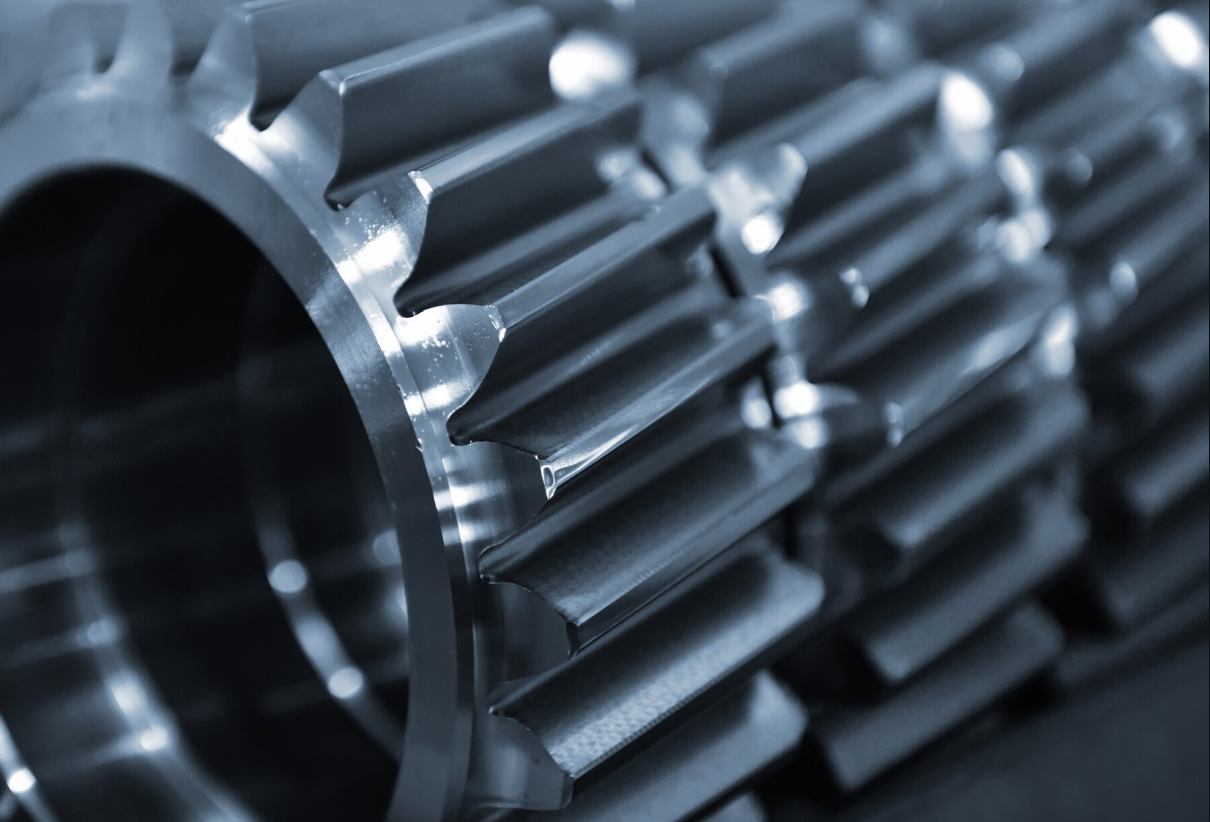

The Die Casting Process Explained

Die casting is a metal forming process where molten metal is injected into a mold cavity under high pressure. The process involves four key stages:

1. Clamping – The die halves are securely clamped together to withstand the pressure of molten metal injection.

2. Injection – Molten metal is forced into the die cavity at high speed, ensuring precise part formation.

3. Cooling – The metal solidifies within the mold, forming the desired shape with high accuracy.

4. Ejection – The finished casting is ejected from the die, ready for post-processing or assembly.

Die casting offers numerous advantages, including high production rates, exceptional accuracy, and minimal material wastage. However, achieving consistent quality requires advanced die casting machines?that offer precision control and efficiency.

This is where YIZUMI excels. Our HII-S Series die casting machines?integrate cutting-edge technology to enhance casting precision, optimize energy efficiency, and improve cycle times—making them the ideal choice for manufacturers looking for reliable die casting solutions.

Essential Die Casting Machines

Selecting the right die casting machine?is crucial for achieving high-quality production. At YIZUMI, we offer advanced solutions that combine precision, efficiency, and durability?to maximize manufacturing performance.

HII-S Series High-end Cold Chamber Die Casting Machine (1000-5000T)

Our HII-S Series die casting machines?are engineered to meet the needs of global manufacturers, offering:

· Precise and stable operation – The human-centric HMI system ensures seamless control, improving casting accuracy and reducing pressure build-up time.

· Efficiency and durability – A re-engineered toggle system and optimized hydraulic drive reduce cycle time while increasing energy efficiency.

· Wide range of applications – With improved rigidity and a modular design, our machines are built for long service life, ensuring lower operational costs.

· Safety and reliability – Adhering to the highest safety standards, we provide reliable die casting production?through HMI-supported data display.

· User-friendly design – Our machines feature international-quality components, ensuring high availability and easy maintenance.

· Modular design for quick delivery – Each module undergoes rigorous testing to guarantee superior product quality and rapid delivery.

Advanced Injection and Clamping Systems

· Enhanced clamping unit – Increased platen rigidity and shorter cycle times significantly boost production output.

· Upgraded injection unit – Improved acceleration and shortened pressure build-up time ensure greater consistency in the casting process.

· Fast and precise hydraulic system – Our system optimizes the balance between energy consumption and efficiency, maximizing OEE (Overall Equipment Effectiveness).

· International-standard electrical control system – Intelligent and precise control ensures a safe and seamless?die casting process.

With these features, YIZUMI die casting machines?empower manufacturers to achieve superior product quality and higher efficiency, making them an excellent investment for companies looking to enhance their production capabilities.

Applications of Die Casting

Die casting plays a crucial role in various industries, enabling the production of complex, high-quality metal components. Key applications include:

Automotive Industry

Die casting is extensively used in the automotive sector for manufacturing engine components, transmission cases, structural parts, and battery housings. Our HII-S Series die casting machines?offer high precision and excellent repeatability, making them ideal for EV and traditional automotive manufacturing.

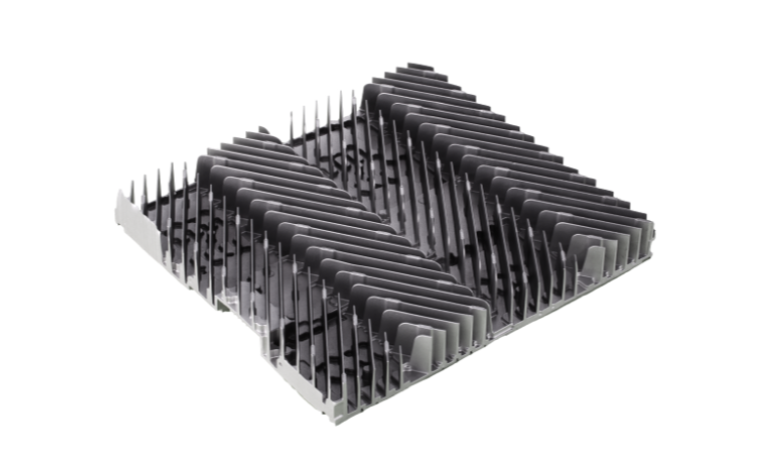

Electronics and Telecommunications

With the growing demand for lightweight and heat-resistant components, die casting is essential for producing electronic casings, connectors, and heat sinks. YIZUMI die casting solutions?provide consistent quality?for intricate components.

Home Appliances

Refrigerators, washing machines, and other home appliances require durable and aesthetically appealing parts. Our integrated die casting?approach ensures high-quality, defect-free castings?with superior finish and durability.

Medical and Aerospace Sectors

Precision and material integrity are critical in the medical and aerospace industries. Our HII-S Series machines?offer strict process control and high-performance output, ensuring compliance with stringent industry standards.

By integrating YIZUMI die casting machines?into these industries, manufacturers can enhance product performance, reduce waste, and optimize production costs.

Why Choose YIZUMI for Die Casting Solutions?

At YIZUMI, we are more than just a die casting machine provider—we offer a complete molding equipment solution. Our expertise in rubber, die casting, and injection molding technologies?allows us to deliver cutting-edge solutions tailored to diverse industries.

Our Advantages:

· Innovative Engineering – With international R&D collaboration, we continuously improve die casting technology?to meet global demands.

· Precision and Efficiency – Our advanced hydraulic and injection systems?ensure consistent, high-quality production.

· Cost-Effective Solutions – Optimized machine performance translates into reduced operational costs and higher ROI.

· Global Market Presence – As a leading manufacturer, we serve automotive, electronics, aerospace, and other high-demand industries?worldwide.

· Comprehensive Support – We provide technical assistance, training, and after-sales service?to ensure maximum machine uptime.

As manufacturing continues to evolve, investing in high-quality die casting solutions?is essential for staying competitive. YIZUMI die casting machines?offer a powerful combination of precision, efficiency, and reliability, helping manufacturers achieve higher productivity and superior product quality.

Die casting remains a cornerstone of modern manufacturing, enabling the production of high-performance metal components across various industries. By leveraging YIZUMI die casting machines, businesses can optimize their production processes, improve part quality, and enhance efficiency.

For those seeking a trusted partner in die casting solutions, YIZUMI provides cutting-edge technology, robust engineering, and industry expertise—ensuring long-term success in an ever-evolving market.

Whether you're in the automotive, electronics, or industrial sector, choosing YIZUMI die casting machines?is a step toward higher efficiency, precision, and profitability.