Die Casting vs. Other Manufacturing Processes: Which is Right for Your Business?

Abstract:

Choosing the right manufacturing process impacts efficiency, cost, and quality. This article compares die casting with other methods and shows how YIZUMI's LEAP Series enhances precision, energy efficiency, and automation.

Introduction to Manufacturing Processes

Manufacturing is at the heart of industrial production, with multiple processes available to create metal and plastic components.

· Die Casting – Uses high pressure to force molten metal into a mold, producing highly precise parts.

· Injection Molding – Similar to die casting but for plastic components, offering scalability and cost efficiency.

· Forging – Involves shaping metal through compressive forces, leading to strong and durable parts.

· Machining – Utilizes cutting tools to remove material and shape parts, allowing for extreme precision but generating waste.

· Stamping – Forms metal sheets into specific shapes, often used in automotive and electronics industries.

Each manufacturing process has its own distinct advantages and drawbacks, depending on the specific requirements of the project. For businesses aiming for high-volume production with consistent precision and efficiency, die casting often stands out as the preferred solution. It enables the creation of complex shapes with tight tolerances, making it ideal for industries that require both high-quality results and cost-effective mass production.

Die Casting: Pros and Cons

Pros of Die Casting

? High Precision and Complexity – Die casting allows for intricate designs with tight tolerances.

? Excellent Surface Finish – Minimal post-processing is needed compared to forging or machining.

? High Production Speed – Suitable for large-scale production with reduced cycle times.

? Material Efficiency – Generates less waste than machining, improving sustainability.

? Strong and Lightweight Parts – Ideal for industries like automotive, aerospace, and electronics.

Cons of Die Casting

? Initial Tooling Costs – Die casting molds are expensive, making it costlier for low-volume production.

? Material Limitations – Primarily suited for non-ferrous metals like aluminum, zinc, and magnesium.

? Porosity Issues – Trapped air in the casting process can create defects if not controlled properly.

Despite its limitations, die casting continues to be one of the most cost-effective and efficient solutions for mass production. It offers high-speed production, excellent dimensional accuracy, and the ability to create complex shapes at a competitive cost. But how does die casting measure up against other manufacturing processes, such as injection molding, forging, or machining?

Comparing Die Casting to Other Processes

| Factor | Die Casting | Injection Molding | Forging | Machining | Stamping |

| Material | Metals (Aluminum, Zinc, Magnesium) | Plastics | Metals | Metals | Metals |

| Production Speed | High | High | Medium | Slow | Fast |

| Precision | High | High | Medium | Very High | Medium |

| Surface Finish | Excellent | Excellent | Moderate | Excellent | Moderate |

| Cost Efficiency | High for mass production | High for mass production | High for strength applications | Costly due to material waste | High |

| Strength | Moderate | Low | Very High | High | Moderate |

From this comparison, it’s clear that die casting stands out as the ideal choice when high-speed production, precision, and an excellent surface finish are top priorities. Its ability to produce complex shapes with tight tolerances and smooth surfaces makes it highly valuable in industries that require both efficiency and quality. However, to fully capitalize on these advantages, businesses need advanced die casting machines that optimize performance and maintain high standards. This is where YIZUMI's LEAP Series Die Casting Machine truly makes a difference, offering cutting-edge technology that enhances automation, energy efficiency, and overall product consistency.

How YIZUMI Helps You Choose the Right Process

At YIZUMI, we understand the challenges manufacturers face in selecting the optimal production method. Our LEAP Series Die Casting Machine?is designed to push the boundaries of efficiency, precision, and energy savings in die casting.

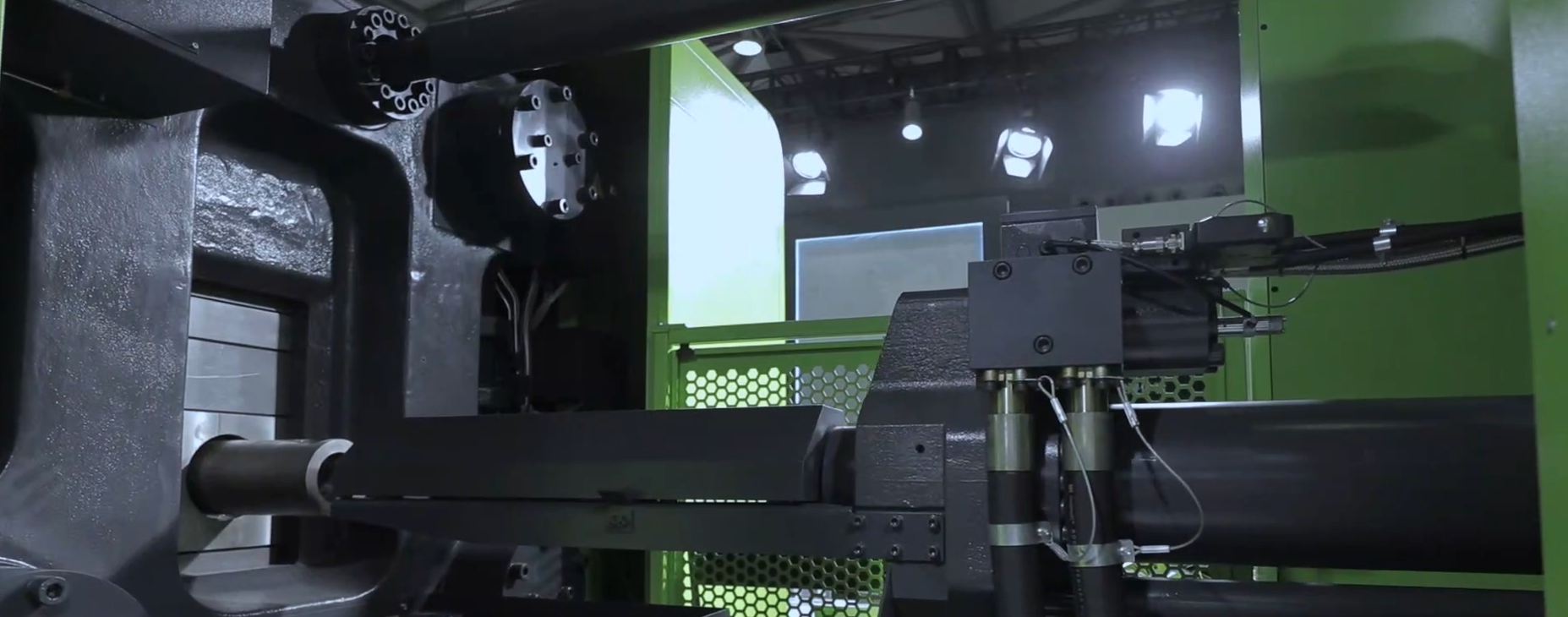

LEAP Series Die Casting Machine: A Game-Changer

Our LEAP Series redefines modern die casting technology?with intelligent, high-performance solutions:

l Precision & Repeatability – Featuring Yi-Cast self-learning real-time control, our machine ensures superior accuracy in every casting cycle.

l Energy Efficiency – The Yi-drive Pump Unit?utilizes servo + feed technology, achieving up to 40% energy savings, reducing operational costs significantly.

l Smart Injection System – The Yi-Cast Injection System?provides closed-loop real-time control, eliminating the need for extensive manual adjustments while ensuring perfect flow control.

l Advanced ORCA Control System – Equipped with a 24-inch industrial touch panel, the ORCA-HMI interface?offers intuitive and user-friendly operation, streamlining the die casting process.

l Intelligent Die Opening/Closing System – Enables ±1mm repeatability accuracy, automatic clamping force detection, and die height adjustment for consistent quality.

With YIZUMI's LEAP Series Die Casting Machine, businesses can increase production efficiency, reduce waste, and enhance product quality—a decisive advantage in today’s competitive manufacturing landscape.

FAQ

Q1: When should I choose die casting over injection molding?

If you're working with metal components?and need high precision, mass production capability, and minimal post-processing, die casting is the superior choice. Injection molding is more suitable for plastic parts.

Q2: Is die casting suitable for small production runs?

While die casting is best for high-volume production, modern solutions like YIZUMI's LEAP Series?optimize cost-efficiency, making it viable for mid-sized runs as well.

Q3: How does YIZUMI improve energy efficiency in die casting?

Our Yi-drive Pump Unit?and Yi-Cast Injection System?reduce energy consumption by up to 40%, making die casting more sustainable and cost-effective.

Q4: What industries benefit most from die casting?

Automotive, aerospace, consumer electronics, and industrial machinery?all rely on die casting for lightweight, durable, and precise metal components.

Choosing the right manufacturing process is critical for achieving optimal efficiency, controlling costs, and ensuring product quality. While processes like forging, machining, and stamping each offer distinct advantages, die casting emerges as the ideal choice for producing high-precision, large-scale metal components. It offers excellent dimensional accuracy, smooth surfaces, and the ability to create complex shapes, making it particularly well-suited for industries requiring high-volume production with stringent quality standards.

With YIZUMI's LEAP Series Die Casting Machine, manufacturers gain cutting-edge technology, intelligent automation, and energy-saving solutions?that boost productivity while reducing costs.

If you're looking for the best die casting solution, YIZUMI?has the expertise and innovation?to support your business’s success.