Hot Chamber Die Casting Machine Applications: Key Industries & Benefits

Abstract:

Hot chamber die casting machines play an essential role in modern manufacturing, especially for industries that rely on precision, speed, and cost efficiency in producing high-volume metal components. Compared with other die casting processes, hot chamber systems are particularly suitable for alloys with lower melting points, such as zinc and magnesium. Their versatility, combined with stable performance, makes them the go-to choice for many die casting machine manufacturers and industrial hot chamber users worldwide.

Hot chamber die casting machines play an essential role in modern manufacturing, especially for industries that rely on precision, speed, and cost efficiency in producing high-volume metal components. Compared with other die casting processes, hot chamber systems are particularly suitable for alloys with lower melting points, such as zinc and magnesium. Their versatility, combined with stable performance, makes them the go-to choice for many die casting machine manufacturers and industrial hot chamber users worldwide.

This article explores the applications of hot chamber die casting machines across different industries, highlights the benefits for businesses, and introduces YIZUMI’s advanced hot chamber die casting solutions.

Understanding Hot Chamber Die Casting Machines

A hot chamber die casting machine integrates the furnace directly with the injection system. The molten alloy is kept at a stable temperature in the furnace, and when required, a plunger draws the molten metal into the chamber and injects it into the die cavity. This integrated process offers several unique advantages:

Fast Cycle Times

Because the molten metal is already inside the machine, there is no need for external transfer. Each shot can be completed faster than in cold chamber systems, which significantly increases production speed. For manufacturers running continuous batches, this translates into thousands of extra components per day.

YIZUMI Hot Chamber Die Casting Machine

Energy Efficiency

The direct-feed design minimizes heat loss during transfer and reduces energy consumption. Over large-scale operations, this energy savings can make a substantial impact on overall production costs.

Precision and Consistency

Hot chamber die casting ensures excellent repeatability. Thin-walled, complex shapes can be cast with tight tolerances, making it an attractive option for industries such as consumer electronics and automotive.

Reduced Labor and Operational Costs

The automation-friendly process simplifies operator tasks and reduces handling errors. Less scrap and rework further optimizes the cost per unit.

Key Industries Using Hot Chamber Die Casting Machines

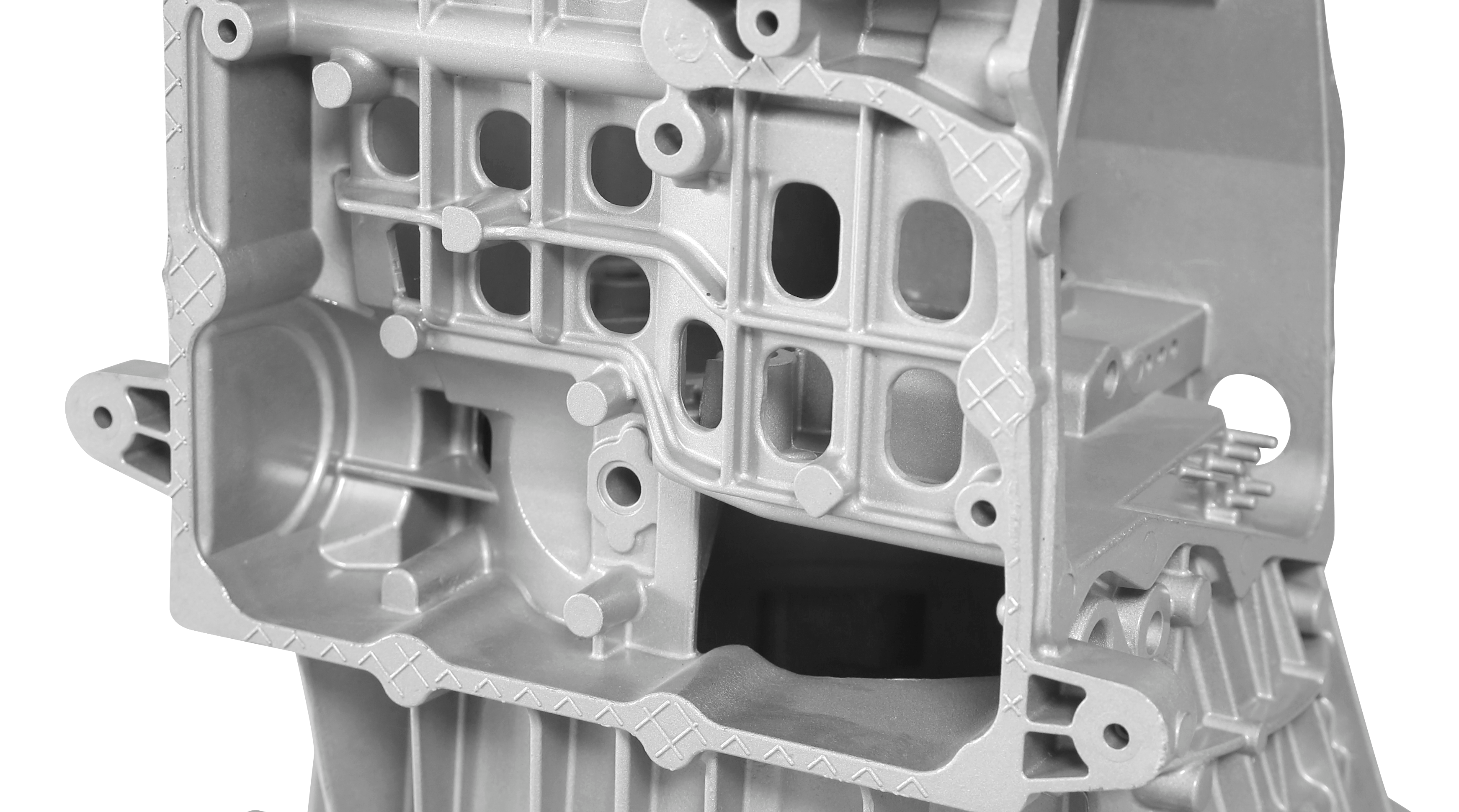

1. Automotive Components

The automotive industry requires millions of small, durable components every year, many of which must meet stringent safety and performance standards. Hot chamber die casting fits these requirements perfectly:

Small Precision Parts: Zinc die casting is widely used for carburetor parts, housings for gears, and electrical system connectors. These parts must withstand wear, vibration, and environmental stress.

Lightweight Alternatives: Magnesium castings are increasingly used to replace heavier steel parts. For example, steering column brackets and electronic housings benefit from magnesium’s light weight and strength.

Scalability: Because automotive demand is high, the ability of hot chamber machines to produce at speed with minimal defects ensures OEMs and suppliers can scale up efficiently.

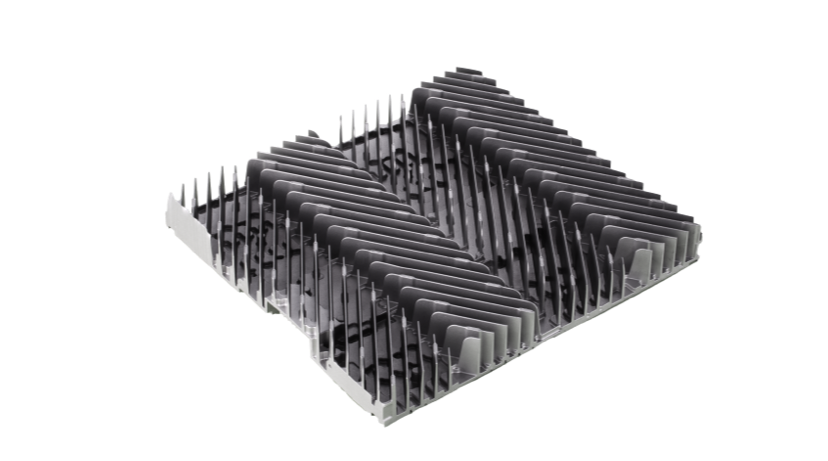

2. 3C (Computer, Communication, and Consumer Electronics)

Electronics manufacturing demands extreme precision and lightweight designs. Hot chamber die casting machines are essential here:

Thin-Wall Production: Magnesium alloys are perfect for mobile phone frames, tablet casings, and laptop housings. Hot chamber machines can cast walls as thin as 0.5 mm without sacrificing strength.

5G Infrastructure: With the growth of 5G, precision cast parts such as antenna housings and connectors require consistent, high-quality production.

High Aesthetic Standards: Consumer electronics also demand smooth surfaces suitable for coatings and finishes. Hot chamber die casting achieves this without costly post-processing.

3. Bathroom and Home Furnishing Hardware

Zinc alloys dominate bathroom and furniture hardware manufacturing because they combine durability with a premium look. Hot chamber machines serve this industry in multiple ways:

Corrosion Resistance: Zinc castings resist water exposure, making them ideal for faucets, handles, and shower components.

Design Flexibility: Decorative pieces like cabinet knobs, curtain hooks, and door handles require complex shapes and fine surface details. Hot chamber die casting reproduces these details reliably.

High-Volume Consistency: Hotel, office, and residential projects demand uniform finishes across thousands of identical components. Industrial hot chamber systems ensure this consistency.

Die Casting For 5G/3C Products

4. Construction and Fittings

In construction, hardware parts need to balance durability with cost-efficiency. Examples include:

Door Locks and Hinges: Produced in high volumes, these require both mechanical strength and aesthetic appeal.

Fasteners and Brackets: Zinc and magnesium cast fasteners can be produced quickly, with surface treatments applied for enhanced wear resistance.

Connector Pieces: Many fittings in modular furniture and building systems rely on precise dimensions to guarantee seamless assembly, which hot chamber die casting can achieve reliably.

5. Consumer Goods and Small Appliances

Everyday items are another important market:

Household Appliance Components: Small motor housings, knobs, and handles are often produced using zinc die casting.

Fashion and Accessories: Zippers, buckles, and belt fittings rely on the cost-efficiency of hot chamber casting.

Toys and Sporting Goods: Strong but lightweight parts such as joints, grips, and fixtures can be manufactured at scale.

Benefits of Hot Chamber Die Casting Machines

1. High Production Efficiency

Cycle times are typically shorter than 10 seconds, depending on part complexity. This means one machine can produce tens of thousands of parts per week. For high-volume industries like automotive and electronics, this ensures production goals can be met without expanding floor space or labor costs.

2. Enhanced Precision and Quality

Modern hot chamber systems are equipped with two-stage injection controls and proportional valves, allowing pressure and speed to be adjusted precisely. This ensures dimensional accuracy even in thin-wall or complex components, reducing costly defects and scrap.

3. Cost-Effectiveness

Because the molten metal feed is internal, less handling is required, reducing both labor costs and energy usage. Scrap rates are low, and consistent quality reduces the need for rework, all of which contribute to a lower cost per part.

4. Material Versatility

Hot chamber die casting machines are primarily designed for zinc and magnesium alloys. Zinc’s corrosion resistance makes it ideal for hardware, while magnesium’s light weight is essential in automotive and electronics. Manufacturers benefit from being able to address multiple markets with a single type of equipment.

5. Long-Term Reliability

Industrial hot chamber machines are designed to withstand continuous operation under high stress. Features like chromium-plated tie bars and ductile iron platens extend the service life of molds and reduce downtime. For buyers, this translates to a lower total cost of ownership.

Hot Chamber Die Casting Machine Supplier

YIZUMI HM Series Hot Chamber Die Casting Machines

As one of the globally recognized die casting machine manufacturers, YIZUMI has developed the HM Series hot chamber die casting machine to meet the diverse demands of modern industries.

Optimized Alloy Production

Zinc Alloys (90–400T): Perfect for bathroom fittings, home hardware, and decorative components. The HM Series ensures robust output with consistent surface finishes.

Magnesium Alloys (200–400T): Specially designed for high-efficiency thin-wall casting in electronics and automotive parts. This enables manufacturers to achieve ultra-lightweight yet strong designs.

High-Speed & Stable Clamping

Optional high-speed clamping reduces cycle times, improving overall equipment effectiveness.

Ductile cast iron platen enhances rigidity, protecting the mold and reducing flash.

Chromium-plated tie bars extend service life and minimize maintenance downtime.

High-Precision Injection

A two-stage injection system ensures smooth filling and consistent density, even in complex molds.

Parameters can be finely tuned to match different part requirements.

Advanced Heating System

The electronic heating system for the nozzle and gooseneck provides precise temperature control, reducing casting defects caused by uneven heating.

Fast, Sensitive Control

Dry injection speeds ≥5 m/s.

Proportional valve technology allows real-time control of pressure and flow, ensuring stable operation and faster process adjustments.

Industry Applications

Automotive: Small gear housings, brackets, and electronic modules.

3C Electronics: Mobile casings, connectors, and laptop housings.

Bathroom Hardware: Faucets, handles, and shower components.

Construction Fittings: Hinges, locks, and brackets.

Conclusion

From automotive parts to 5G electronics and bathroom fittings, hot chamber die casting machines are indispensable in modern manufacturing. Their ability to deliver precision, speed, and cost efficiency makes them a preferred solution for industries worldwide.

YIZUMI’s HM Series hot chamber die casting machine stands out with its advanced clamping, precision injection, and specialized alloy applications. As one of the trusted die casting machine manufacturers, YIZUMI provides businesses with high-performance hot chamber solutions that support long-term growth and competitiveness.