Injection compression function for the packaging industry

Abstract:

Challenging application on high-performance injection moulding machine YIZUMI

The packaging industry is in a perpetual quest for innovative solutions to meet escalating demands for high-performance, efficient, and sustainable packaging solutions. A groundbreaking advancement in this pursuit is the injection compression function, revolutionizing the capabilities of injection moulding machines. Leading the charge is YIZUMI, renowned for manufacturing cutting-edge moulding equipment. YIZUMI has seamlessly incorporated the injection compression function into their high-performance injection moulding machines. This article delves into how YIZUMI's advanced technology tackles the complex challenges of the packaging industry, setting new standards for innovation and efficiency.

YIZUMI combines injection-compression function of thin-walled containers with the use of stack moulds

Injection compression moulding is a thermoplastic moulding process where the melt is injected into a partially open mold and then compressed either simultaneously or subsequently. This compression occurs during the machine's closing stroke or via a coining core within the mold. This method effectively reduces cavity pressure, particularly beneficial for moulding extremely thin-walled parts. Additionally, the compression process minimizes internal stress on molded components and enhances dimensional accuracy, making it ideal for a range of applications including packaging and automotive parts like lighting components.

The injection compression function is particularly beneficial for producing thin-walled containers, which are widely used in the packaging industry. By combining this function with the use of stack molds, YIZUMI has achieved significant advancements in efficiency and productivity. Stack molds allow for the simultaneous production of multiple parts, effectively doubling the output without requiring additional machinery or space.

The injection compression function involves compressing the injected material within the mold cavity, resulting in a more uniform distribution of the plastic. This technique reduces internal stresses and improves the mechanical properties of the final product. YIZUMI's integration of this function ensures that thin-walled containers are produced with greater precision, consistency, and strength, meeting the stringent requirements of the packaging industry.

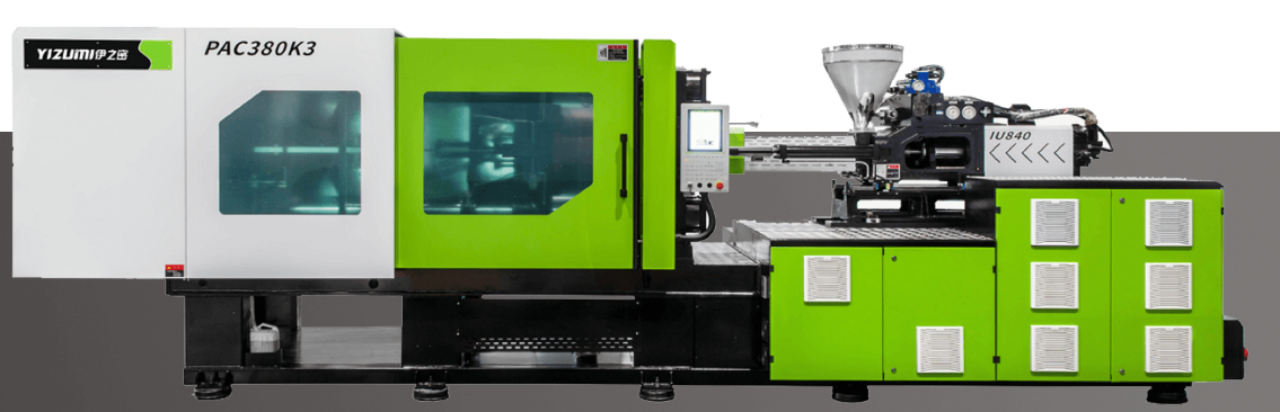

Recovering energy with the PAC-K3

The PAC-K3 Series from YIZUMI stands out in the field of injection moulding with its array of advanced features, setting a new standard for precision, efficiency, and reliability in industrial applications. It enhances equipment power, injection rate, precision, and energy efficiency, thereby ensuring superior injection stability.

It incorporates highly responsive servo motors to boost system pressure and injection speed, ensuring stable production of thin-walled and multi-cavity products.

Models like the PAC-K3 include upgraded hydraulic synchronized layer compression, effectively reducing product cycle times.

Improved closing mechanisms provide enhanced mold locking force, simplifying the moulding of thin-walled and deep-cavity products.

The PAC-K3 series is equipped with the Iventure system for faster response times and precise control.

Its user-friendly design facilitates convenient daily operations and maintenance.

Widely applicable across industries including food packaging, beverage packaging, and disposable medical supplies.

The injection compression function, when combined with the PAC-K3 system, offers manufacturers a more sustainable production method. This integration not only enhances the performance of the injection moulding machine but also aligns with global efforts to reduce carbon footprints and promote energy conservation in the manufacturing sector.

System solutions for a successful circular economy

In the context of a circular economy, which aims to minimize waste and maximize resource efficiency, YIZUMI's injection compression function assumes a pivotal role. This advanced technology enables the production of high-quality, thin-walled containers while using minimal material, aligning perfectly with the principles of sustainability inherent in the circular economy.

Beyond technological innovation, YIZUMI demonstrates a profound commitment to sustainability across their operations. We provide holistic system solutions that support the entire lifecycle of products, from initial design and manufacturing to eventual recycling and repurposing. By integrating the injection compression function into their systems, the manufacturers can develop packaging solutions that not only excel in performance but also uphold environmental stewardship.

By focusing on efficiency and minimizing material usage, YIZUMI facilitates the creation of packaging solutions that reduce environmental impact without compromising on quality. This approach not only meets the stringent demands of today's market but also contributes positively to the sustainable practices essential for a circular economy. Through continuous innovation and comprehensive support, YIZUMI remains at the forefront of promoting sustainable manufacturing practices across the industry.

State-of-the-art injection moulding systems for the demanding packaging industry

The packaging industry is characterized by its stringent requirements for precision, efficiency, and reliability. YIZUMI's advanced injection moulding systems, which incorporate state-of-the-art injection compression technology, are specifically tailored to meet these exacting demands. These systems excel in managing complex and challenging applications, enabling manufacturers to consistently deliver high-quality packaging solutions on a large scale.

YIZUMI's injection moulding machines are meticulously engineered to deliver superior performance and versatility. The integration of the injection compression function represents a significant enhancement to the moulding process. By reducing cycle times, enhancing product quality, and boosting overall productivity, YIZUMI empowers manufacturers to maintain a competitive edge in the dynamic packaging industry.

The injection compression function not only optimizes manufacturing efficiency but also ensures that every product meets rigorous quality standards. This technological advantage enables YIZUMI's systems to effectively address the evolving needs of modern packaging applications, where speed, precision, and reliability are paramount.

In a word, YIZUMI's dedication to innovation and excellence in injection moulding technology enables manufacturers to achieve operational excellence and product superiority in the fast-paced and demanding landscape of the packaging industry.

Conclusion

The injection compression function represents a significant advancement in injection moulding technology, offering numerous benefits for the packaging industry. YIZUMI's innovative approach to integrating this function into their high-performance injection moulding machines demonstrates their commitment to excellence and sustainability. By leveraging the injection compression function, manufacturers can produce thin-walled containers with greater efficiency, precision, and quality. The combination of stack molds and energy recovery systems like PAC-K3 further enhances the sustainability and cost-effectiveness of the production process. YIZUMI's comprehensive system solutions support a successful circular economy, enabling manufacturers to create environmentally friendly packaging solutions that meet the highest standards. As the packaging industry continues to evolve, YIZUMI remains at the forefront, providing state-of-the-art injection moulding systems designed to tackle the most demanding applications.

For manufacturers looking to enhance their production capabilities and embrace sustainable practices, YIZUMI's injection compression function offers a powerful solution. With YIZUMI's expertise and advanced technology, the future of packaging is brighter, more efficient, and more sustainable than ever before.