Integrated Die Casting Technology: Revolutionizing Lightweight Automotive Components

Abstract:

Discover how YIZUMI integrated die casting machines optimize magnesium alloy processes and reduce carbon footprint in automotive.

In the evolving landscape of automotive manufacturing, integrated die casting technology has emerged as a game-changing solution. This innovative approach enables manufacturers to produce large, complex, and lightweight components with higher precision, fewer assembly points, and increased overall structural integrity. As global OEMs seek better solutions to reduce both production costs and carbon emissions, integrated casting is becoming a critical pillar in the lightweight automotive die casting process. And at the forefront of this revolution is YIZUMI—a technology-driven company committed to advanced forming equipment and complete solution integration.

Cost and Carbon Footprint Reduction Through Integrated Casting

Reducing the weight of automotive components is not just about fuel efficiency anymore. It’s about meeting stringent environmental regulations, enhancing electric vehicle (EV) range, and improving structural safety. Traditional manufacturing methods involve welding or fastening multiple stamped parts together, which adds weight, increases labor costs, and creates more opportunities for failure.

By contrast, integrated die casting?allows for the production of large components such as rear underbodies, front modules, and battery enclosures in a single shot. This eliminates the need for dozens of smaller parts, significantly reducing assembly time, raw material usage, and overall energy consumption. For manufacturers, this translates to lower costs. For the planet, it means a reduced carbon footprint.

Moreover, integrating die casting technology with high-performance materials like magnesium alloys?offers even greater environmental and performance benefits. Magnesium is 33% lighter than aluminum and offers excellent strength-to-weight ratios, making it ideal for next-generation EV platforms.

Process Optimization for Magnesium Alloy: Simulation-Driven Precision

However, working with magnesium alloys requires highly controlled processing conditions to avoid common defects like porosity, shrinkage, or hot cracking. That’s where magnesium alloy casting defect control?becomes crucial. Using advanced simulation tools such as flow analysis, thermal mapping, and cooling optimization, manufacturers can predefine the best injection parameters to avoid turbulent flow and inconsistent solidification.

For example, simulations show that optimizing gate placement and injection speed in magnesium casting can reduce porosity by up to 40%. Controlled cooling and mold temperature balancing further enhance surface quality and dimensional accuracy.

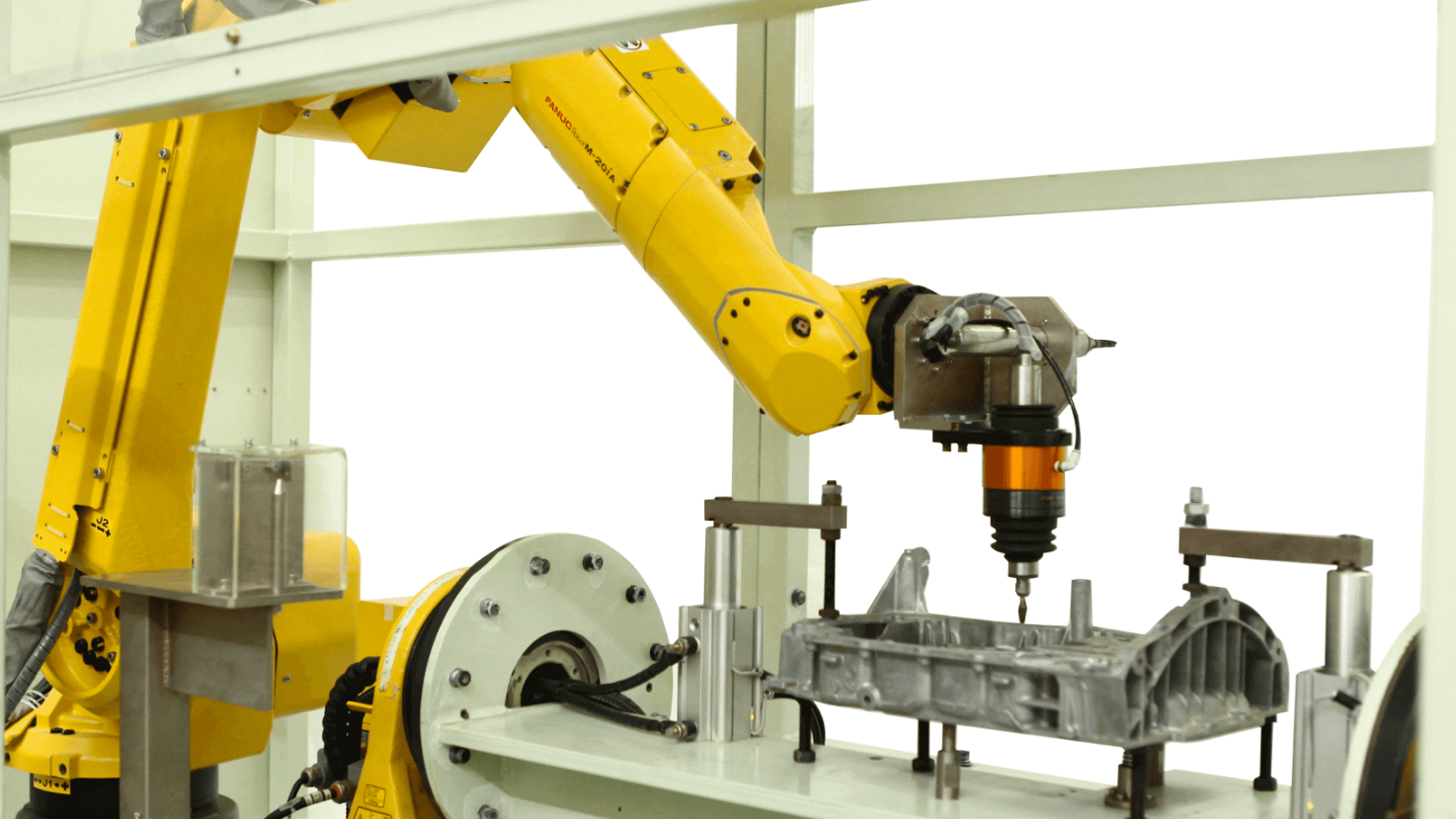

This level of precision can only be achieved with equipment designed for consistency and control—an area where YIZUMI integrated die casting machines?truly stand out. The transition from simulation to production requires machines that can match the precision of virtual models, and that’s exactly what our technology delivers.

Introducing the YIZUMI HII-S Series: Smart, Efficient, and Built for the Future

To meet the growing demand for efficiency, accuracy, and high uptime in die casting, we developed the HII-S Series High-end Cold Chamber Die Casting Machine (180-900T). This series integrates decades of engineering expertise with our proprietary LEAP technology platform, delivering unmatched performance in the most demanding environments.

Key Features of YIZUMI HII-S Series:

l Precision and Stability: Our human-centric HMI design increases operational efficiency. The upgraded injection unit provides top-line acceleration and international-level process repeatability, ideal for complex magnesium alloy castings.

l Efficiency and Durability: A re-engineered toggle system and optimized hydraulic drive significantly shorten cycle times and reduce energy use—aligning perfectly with sustainability goals.

l Flexibility: The modular machine structure accommodates various part sizes and complexities, from small brackets to large structural components.

l Safety and Reliability: We adhere to international safety standards with intelligent hydraulic and electrical systems that ensure reliable, safe operation even in high-output scenarios.

l Ease of Maintenance: With high-quality international hardware and an intuitive layout, the HII-S Series ensures minimal downtime and faster serviceability.

By integrating smart control systems and modular components, the YIZUMI integrated die casting machine?supports real-time data monitoring, MES connectivity, and predictive maintenance—all of which are vital for Industry 4.0-compliant factories.

We’ve specifically designed this machine to enable magnesium alloy casting defect control, allowing customers to produce stronger, lighter, and more consistent parts with fewer rejections and minimal waste.

Tesla-Inspired Applications and the 2031 Market Forecast

The global spotlight on integrated die casting intensified after Tesla's adoption of giant casting machines for its Model Y. Their use of aluminum alloy one-piece castings for the rear underbody eliminated 70 individual parts, reduced assembly time by 30%, and lowered production costs considerably. This move validated the commercial viability of integrated casting and ignited interest across the industry.

Today, many global OEMs—including traditional combustion vehicle makers and EV startups—are investing in integrated die casting lines for battery housings, subframes, and seat structures. This trend is expected to accelerate.

According to market research, the global integrated die casting market is projected to exceed USD 14 billion by 2031, with a CAGR of over 9%. Lightweight automotive die casting processes—especially those using magnesium and aluminum alloys—will account for the largest market share, driven by the demand for EVs and sustainable manufacturing.

Why YIZUMI Is the Partner of Choice for Future-Ready Manufacturers

At YIZUMI, we are more than just an equipment provider. We are your strategic partner in achieving manufacturing excellence. Our offerings span across rubber, plastic, and die casting technologies—backed by deep technical know-how and a commitment to customer success.

We understand the complexity of modern vehicle manufacturing and the urgency to innovate. That’s why our integrated solutions don’t just include machines, but also encompass:

l Process consulting

l Custom simulation services

l Defect diagnostics and control systems

l Global service and training support

When you choose a YIZUMI integrated die casting machine, you're choosing a proven solution built to help you stay ahead of the curve, reduce defects, and improve your overall equipment efficiency (OEE).

Leading the Lightweight Revolution with YIZUMI

The shift toward lightweight, high-efficiency vehicle components is irreversible—and integrated die casting is at the heart of this transformation. With increasing pressure to reduce costs, emissions, and production complexity, manufacturers need equipment that is not just powerful, but smart, stable, and adaptable.

YIZUMI integrated die casting machines?provide the precision, flexibility, and reliability needed to drive innovation in lightweight automotive die casting processes. Backed by our expertise in magnesium alloy casting defect control, and a legacy of core technologies in rubber, injection molding, and die casting, we’re proud to support manufacturers around the world with end-to-end forming equipment solutions.

The future of automotive manufacturing is lighter, smarter, and more sustainable—and we’re here to help you build it.