Maximizing Efficiency in Die Casting: Tips from YIZUMI

Abstract:

Learn how to optimize die casting with expert insights and YIZUMI's LEAP Series Die Casting Machine, improving precision, speed, and energy efficiency.

Die casting is one of the most widely used manufacturing processes for producing metal parts with high precision and consistency. This method enables manufacturers to create complex components with excellent surface finish, tight tolerances, and minimal post-processing. However, achieving efficiency in die casting is critical to maintaining cost-effectiveness, minimizing material waste, and ensuring high-quality output.

Efficiency in die casting directly affects productivity, energy consumption, and profitability. A well-optimized process reduces cycle times, extends machine lifespan, and enhances part quality. Conversely, inefficient die casting operations can lead to production bottlenecks, increased defect rates, and higher operational costs.

For manufacturers looking to stay competitive, investing in advanced technology, optimizing machine performance, and fine-tuning process parameters?are essential steps in achieving the highest levels of efficiency in die casting.

Key Factors Affecting Die Casting Efficiency

Several factors contribute to overall die casting efficiency, from machine selection to process control. Addressing these factors can help manufacturers optimize their production line for maximum output and minimal downtime.

a. Mold Design and Maintenance

The mold is one of the most crucial elements in die casting. A well-designed mold ensures uniform filling, proper cooling, and minimal defects. Key considerations include:

· Thermal Management:?Proper cooling channels prevent overheating and reduce cycle times.

· Venting and Gating:?Efficient air venting and gating systems reduce porosity and enhance mold filling.

· Durability and Coating:?Regular maintenance and protective coatings extend mold life and reduce wear.

Neglecting mold maintenance can lead to increased scrap rates and inconsistent part quality, negatively impacting production efficiency.

b. Injection Molding Parameters

Precise control of injection parameters ensures optimal casting results. Critical parameters include:

· Injection Speed and Pressure:?Properly adjusted settings prevent defects like cold shuts and incomplete filling.

· Temperature Control:?Maintaining the right temperature minimizes warping and shrinkage.

· Dwell Time:?Optimizing dwell time ensures proper solidification and improves dimensional accuracy.

A servo injection molding machine?provides real-time adjustments and enhanced stability, making it an ideal choice for manufacturers seeking higher precision and repeatability.

c. Machine Performance and Automation

Die casting machines play a central role in achieving high efficiency. Modern servo injection molding machines?and die casting equipment offer significant advantages, such as:

· Faster cycle times?due to high-speed injection units.

· Lower energy consumption?with servo-driven hydraulic systems.

· Enhanced automation, reducing dependency on manual labor.

Automation solutions, including robotic handling, automated trimming, and real-time process monitoring, further enhance efficiency by reducing variability and human errors.

d. Material Selection and Processing

Choosing the right metal alloy is essential for achieving consistent die casting results. Factors to consider include:

· Thermal Conductivity:?Higher conductivity materials solidify faster, improving cycle times.

· Flow Characteristics:?Alloys with better fluidity reduce the risk of incomplete fills.

· Strength and Durability:?Materials with superior mechanical properties reduce post-processing requirements.

Proper pre-processing techniques, such as degassing and filtration, also improve metal purity and prevent defects.

YIZUMI's Machine for Maximizing Efficiency

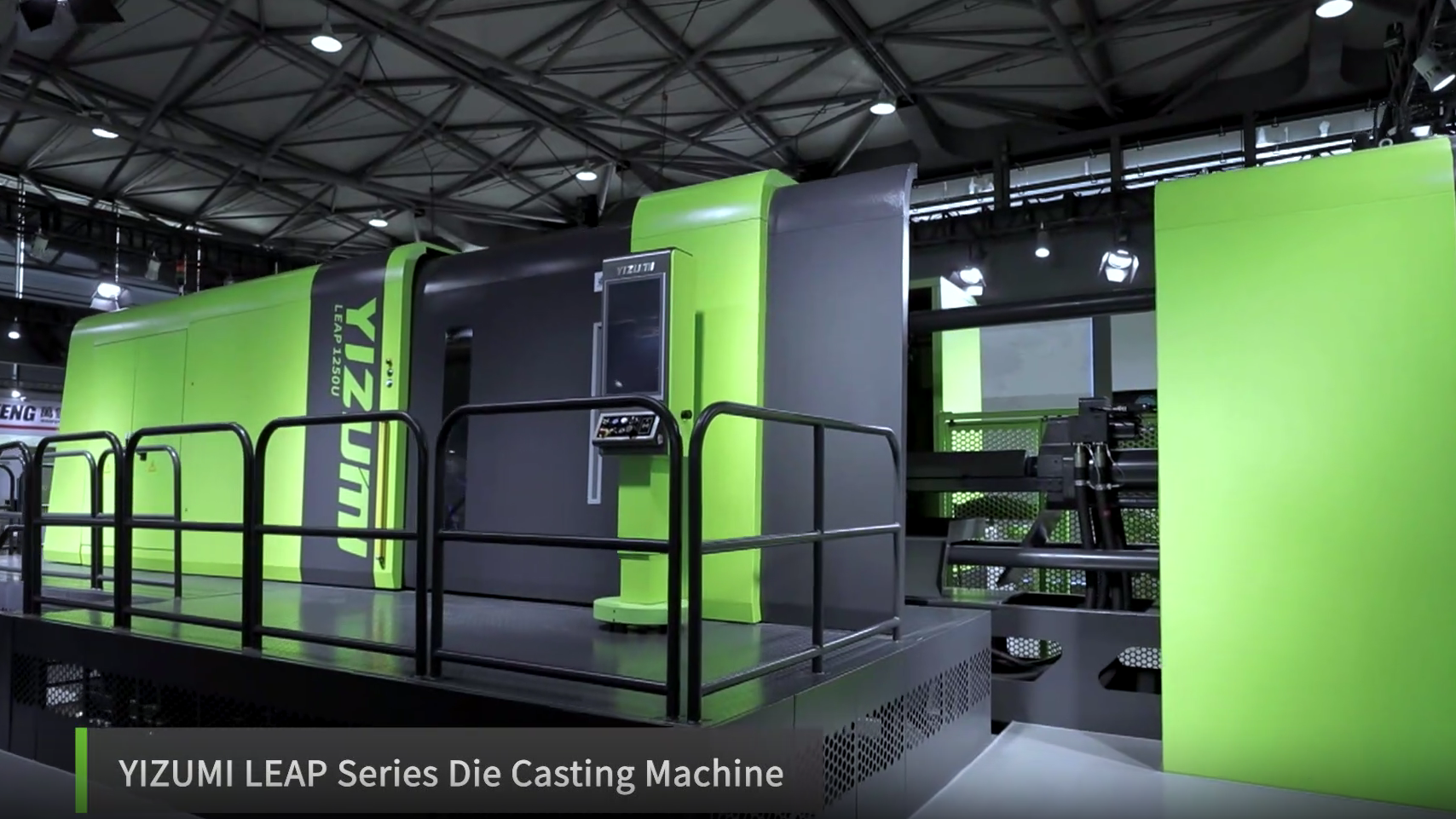

At YIZUMI, we understand the growing demand for high-efficiency die casting solutions. Our LEAP Series Die Casting Machine?is designed to maximize precision, speed, and energy efficiency, providing manufacturers with the best-in-class equipment for high-volume production.

Key Features of the LEAP Series Die Casting Machine

Yi-Cast Real-Time Closed-Loop Injection System

This advanced system ensures that every injection meets strict quality standards by offering real-time monitoring and adjustments. Unlike traditional systems that require constant manual tuning, Yi-Cast adapts automatically to changing conditions, improving repeatability and reducing scrap rates.

ORCA Control System for Enhanced Performance

The ORCA Control System?is one of the most intuitive and responsive?control units in the industry. Equipped with a 24-inch touch panel, it allows operators to easily:

· Adjust injection parameters.

· Monitor machine status in real time.

· Access production data and analytics.

By leveraging advanced control algorithms, the ORCA system improves injection precision and significantly reduces setup times.

Yi-Drive Pump Unit for Energy Efficiency

The LEAP Series is built with a highly efficient servo-driven hydraulic system, which offers:

· Up to 40% energy savings?compared to conventional hydraulic machines.

· Lower heat generation, reducing cooling requirements.

· Improved responsiveness, enhancing process stability.

This combination of efficiency and precision makes the LEAP Series a game-changer in the die casting industry.

Why Choose YIZUMI for Efficient Die Casting?

As a global leader in injection molding?and die casting technology, YIZUMI?provides cutting-edge solutions that help manufacturers improve efficiency and product quality. Our commitment to innovation ensures that our customers benefit from:

Superior Machine Performance

Our machines are designed to meet the demands of high-volume production, with high-speed injection units, intelligent control systems, and precision mold clamping technology.

Unmatched Precision and Repeatability

With our Yi-Cast self-learning real-time control system, manufacturers can achieve consistent casting results with minimal variations, reducing material waste and post-processing requirements.

Energy Efficiency and Cost Savings

Our innovative servo + feed pump system?significantly reduces power consumption, making our machines more sustainable and cost-effective in the long run.

User-Friendly Operation

With the ORCA-HMI interface, operators can easily configure settings, optimize production workflows, and ensure maximum efficiency with minimal training.

Comprehensive Support and Service

We provide a full range of support services, from initial setup to ongoing maintenance, helping our customers achieve long-term productivity and success.

FAQ

Q: How does YIZUMI's LEAP Series improve efficiency in die casting?

A: Our Yi-Cast closed-loop injection system?and ORCA control technology?optimize injection parameters in real time, reducing cycle times by 10%?and enhancing precision.

Q: What energy-saving benefits does the LEAP Series offer?

A: The Yi-Drive Pump Unit?integrates servo and feed pump technology, cutting energy consumption by up to 40%?compared to conventional systems.

Q: Is the LEAP Series suitable for complex and high-precision casting applications?

A: Yes, the real-time control system, advanced hydraulic technology, and intelligent die opening/closing features?make it ideal for producing intricate die-cast components.

Q: How does YIZUMI ensure consistent quality in die casting?

A: Our closed-loop injection control, self-learning system, and automated clamping force detection?ensure repeatable, high-quality casting results.

Q: Why should I choose YIZUMI for my die casting needs?

A: YIZUMI offers state-of-the-art technology, energy-efficient solutions, and comprehensive support, helping manufacturers improve efficiency, reduce costs, and achieve superior casting performance.

By investing in YIZUMI's LEAP Series Die Casting Machine, manufacturers gain access to cutting-edge innovations?that enhance efficiency, reduce operational costs, and ensure superior casting quality.