Optimizing Automotive Plastic Parts Production with Flexible Injection Moulding Machines

Abstract:

Explore how advanced injection moulding machines offer precision and flexibility in producing high-quality automotive plastic parts. Learn how YIZUMI's technology meets the industry's stringent standards.

Introduction:

In the competitive automotive industry, producing high-quality plastic components, especially visible and decorative parts, is crucial. Advanced injection moulding machines offer the precision, flexibility, and efficiency needed to meet these demands. This article delves into the versatility of these machines in various production processes and how they help manufacturers maintain top-tier standards in automotive manufacturing.

Section 1: The Versatility of Injection Moulding Machines:

Injection moulding machines are versatile tools essential for producing a wide range of automotive plastic parts. From small, intricate pieces to large, structural components like bumpers, dashboards, and decorative trims, these machines handle the diverse demands of the automotive industry effortlessly. For instance, vertical injection moulding machines excel in overmoulding processes, where inserts like metal components are encapsulated in plastic, a common requirement in automotive assemblies.

Section 2: Detailed Overview of Injection Moulding Machines:

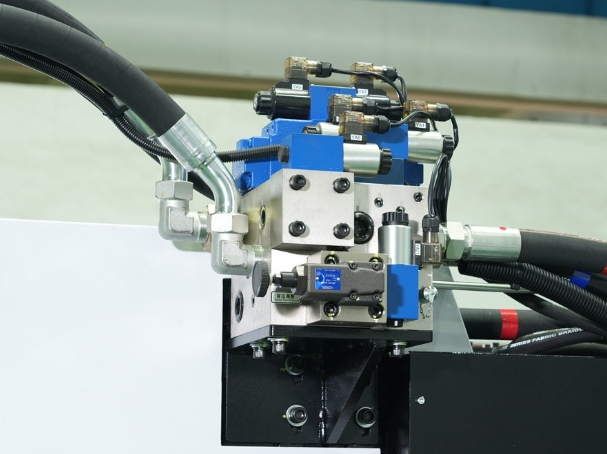

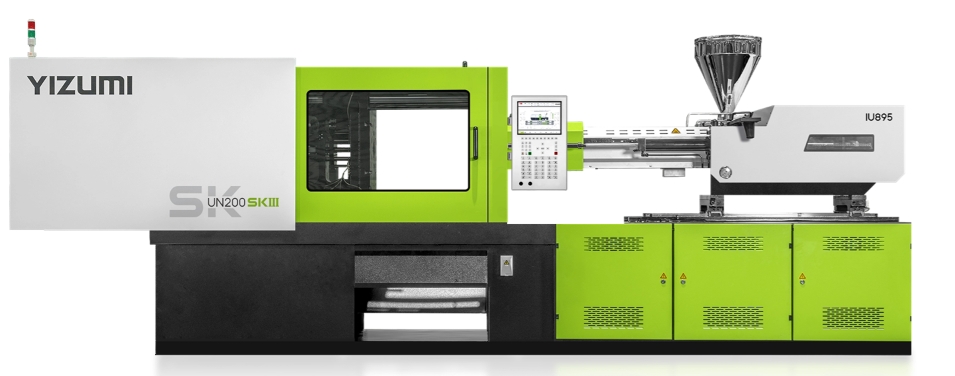

Injection moulding machines consist of several key components, including the injection unit, clamping unit, and mould. The injection unit melts and injects plastic into the mould, while the clamping unit secures the mould during the injection and cooling process. Advanced models like YIZUMI's SKⅢ Series General Purpose Injection Moulding Machine offer superior precision and efficiency, with features like energy-saving servo technology and a robust clamping mechanism that enhances moulding accuracy and reduces energy consumption.

Section 3: Adapting to Diverse Production Processes:

The adaptability of injection moulding machines is crucial for the automotive industry, where diverse parts are constantly in demand. These machines support a wide range of production processes, allowing manufacturers to switch between different materials, mould designs, and techniques with minimal downtime. For example, vertical injection moulding machines can quickly transition between producing different automotive components by simply changing the mould and adjusting process parameters, reducing retooling time and costs.

Section 4: Meeting High Standards for Automotive Plastic Parts:

Automotive plastic parts, particularly those in visible and decorative areas, must meet high standards for appearance, durability, and functionality. Injection moulding machines are designed to produce parts with excellent surface finishes and intricate details, essential for components like interior trims and exterior panels. The precision offered by these machines ensures that every part meets the stringent quality requirements of the automotive industry.

Section 5: Intelligent Process Optimization:

Optimizing the injection moulding process is key to maximizing efficiency and minimizing waste. Modern machines are equipped with intelligent control systems that allow real-time monitoring and adjustment of production parameters. Features like process parameter storage and recall, self-diagnostics, and maintenance checks enhance machine reliability and longevity. YIZUMI’s vertical injection moulding machines, equipped with these advanced features, are ideal for automotive manufacturers aiming to optimize their production processes and reduce energy consumption.

Conclusion:

Injection moulding machines are indispensable in automotive plastic parts production, offering the flexibility, precision, and efficiency needed to meet the industry's high standards. Whether for visible decorative components or complex multi-material parts, these machines are equipped to handle the demands of modern automotive manufacturing. With advanced features like real-time process monitoring and intelligent control systems, YIZUMI’s injection moulding equipment provides manufacturers with the tools to optimize production and maintain a competitive edge. As the automotive industry evolves, the importance of flexible and efficient injection moulding machines will only grow, making them essential assets for manufacturers.