Plastic Injection Molding Machine Solutions: Boosting Efficiency in Manufacturing

Abstract:

Plastic injection molding has become an essential process for producing high-precision, high-volume plastic components across industries. Manufacturers demand machines that combine efficiency, reliability, and precision to meet production goals while reducing operational costs.

Plastic injection molding has become an essential process for producing high-precision, high-volume plastic components across industries. Manufacturers demand machines that combine efficiency, reliability, and precision to meet production goals while reducing operational costs.

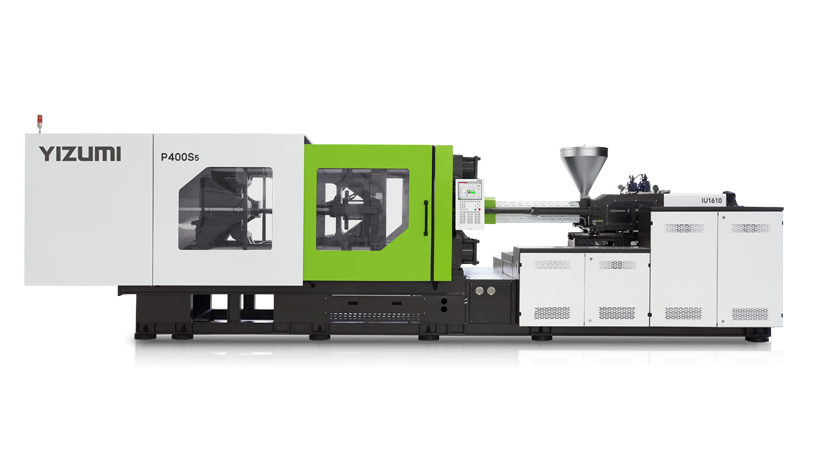

YIZUMI, a leading injection molding machine manufacturer, offers a full range of solutions designed to maximize manufacturing efficiency, including plastic injection molding machines, high-speed injection molding machines, and vertical plastic injection molding machines.

Understanding Plastic Injection Molding Machines

Plastic injection molding machines are specialized equipment used to melt and inject plastic materials into molds to produce components of varying complexity. These machines are widely used across automotive, electronics, medical, packaging, and consumer product industries. The efficiency and precision of an injection molding machine directly impact product quality, production speed, and operational costs.

YIZUMI’s plastic injection molding machines are engineered to provide high stability, consistent performance, and energy efficiency. They are ideal for manufacturers seeking reliable machinery to streamline their production lines.

High-Speed Injection Molding Machines for Rapid Production

For industries with demanding production schedules, high-speed injection molding machines are essential. YIZUMI’s PS5 Series high-speed injection molding machine exemplifies this, offering advanced capabilities that ensure rapid, precise molding for thin-wall and high-volume products.

YIZUMI High-Speed Injection Molding Machine

Key Features of PS5 Series

Clamping Unit: The PS5 series high-speed injection molding machine is equipped with a high-rigidity clamping unit designed through finite element analysis to enhance platen rigidity. The anti-tilt movable platen ensures stability even during high-speed operation, while steel and copper bushings reduce lubricant consumption.

Injection Unit: With low-pressure, high-speed injection and multi-action compound operation, the machine achieves maximum injection speeds up to 550 mm/s. The dual linear guide design minimizes friction, shortens injection acceleration time, and improves overall efficiency.

Hydraulic System: The optimized hydraulic oil circuit reduces energy loss, and multi-pump hydraulic circuits support mold opening synchronized with plasticizing. An optional mold opening synchronized with ejection is also available for specialized applications.

Control System: Imported hydraulic and electrical components ensure superior stability. Intelligent mold opening simplifies parameter settings, while the intelligent clamping force management system maintains optimal force, improving product quality and operational convenience.

The PS5 series high-speed injection molding machine is ideal for applications such as food packaging, medical disposables, bottle caps, and daily chemical products. Its high-speed capabilities, energy efficiency, and precision design make it an essential asset for manufacturers focused on maximizing throughput without compromising quality.

Vertical Plastic Injection Molding Machines for Precision Inserts

Certain applications, such as components with inserts or multi-material designs, require vertical injection molding machines for enhanced precision. YIZUMI’s VM Series vertical plastic injection molding machine provides stable vertical injection and direct clamping, ensuring consistent quality and precise molding.

YIZUMI Vertical Plastic Injection Molding Machine

Highlights of the VM Series

High Precision and Efficiency: The vertical design allows precise control of insert placement and molding. Optimized plasticizing screws improve efficiency by 10%-30%, enhancing both plasticizing quality and color mixing.

Energy-Saving Technology: Equipped with YIZUMI’s third-generation servo system, VM series vertical plastic injection molding machines consume 30%-80% less energy than conventional hydraulic machines while maintaining exceptional reliability and low noise levels.

Advanced Control Systems: The upgraded KEBA system supports multiple modules and communication interfaces, real-time monitoring, and temperature compensation sensors. Proportional back pressure control ensures stable injection, reducing defects and improving part consistency.

Safety Features: Automatic low oil level detection prevents hydraulic instability, protecting the machine and maintaining consistent performance.

The VM series vertical plastic injection molding machine is perfect for molding plastic parts with inserts or components that require high precision, making it suitable for industries like electronics, automotive, and consumer goods.

Why Choose YIZUMI Plastic Injection Molding Machines?

Investing in YIZUMI plastic injection molding machines offers manufacturers numerous advantages that enhance productivity, product quality, and overall operational efficiency:

1. Enhanced Production Efficiency

YIZUMI plastic injection molding machines are designed for high-speed, precise operations, significantly reducing cycle times without compromising accuracy. With advanced automation options and intelligent process controls, manufacturers can achieve faster production rates and meet tight delivery schedules more efficiently.

2. Energy Efficiency

Equipped with state-of-the-art servo motors and optimized hydraulic systems, YIZUMI plastic injection molding machines minimize energy consumption while maintaining peak performance. This translates into lower electricity costs and a smaller environmental footprint, making them an ideal choice for companies focused on sustainability and cost management.

3. Consistent Product Quality

YIZUMI plastic injection molding machines ensure exceptional product consistency through precise injection controls, intelligent clamping force management, and stable hydraulic systems. Manufacturers can produce defect-free components with tight tolerances, reducing material waste and increasing customer satisfaction.

Next-Gen A6 Series Intelligent Injection Molding Machine

4. Versatility Across Applications

From engineering plastics to high-performance polymers, YIZUMI plastic injection molding machines handle a wide range of materials and mold types. Their adaptability allows manufacturers to diversify production, meet custom requirements, and respond quickly to evolving market demands.

5. Durability and Reliability

Built for continuous operation, YIZUMI injection molding plastic injection molding machines feature high-rigidity platens, reinforced clamping units, and premium-quality components. This ensures long-term reliability, minimizing downtime and maintenance costs while supporting large-scale manufacturing.

6. Advanced Technology Integration

YIZUMI plastic injection molding machines incorporate intelligent monitoring systems, data analytics, and IoT connectivity, enabling manufacturers to track performance, optimize processes, and implement predictive maintenance. This leads to higher operational efficiency and reduced risk of production interruptions.

Conclusion

Selecting the right plastic injection molding machine is critical for efficient, high-quality manufacturing. YIZUMI’s plastic injection molding solutions, including high-speed injection molding machines and vertical plastic injection molding machines, provide manufacturers with advanced technology, energy efficiency, and precise control.

By integrating these machines into production lines, businesses can achieve faster cycle times, consistent part quality, and reduced operational costs. For manufacturers seeking reliable and versatile injection molding equipment, YIZUMI offers high-performance injection molding machines that meet the highest industry standards and support continuous improvement in production performance. Please feel free to contact us for more information!