Plastics moulding machines:Maintenance routines to produce on-time, all the time

Abstract:

D-O-W-N. The four-letter word no one wants to hear in injection molding.In today's plastics injection molding manufacturing world, reliability and repeatability are key in machine performance. Being profitable requires a preventive maintenance strategy and maintenance routines to maintain uninterrupted production.

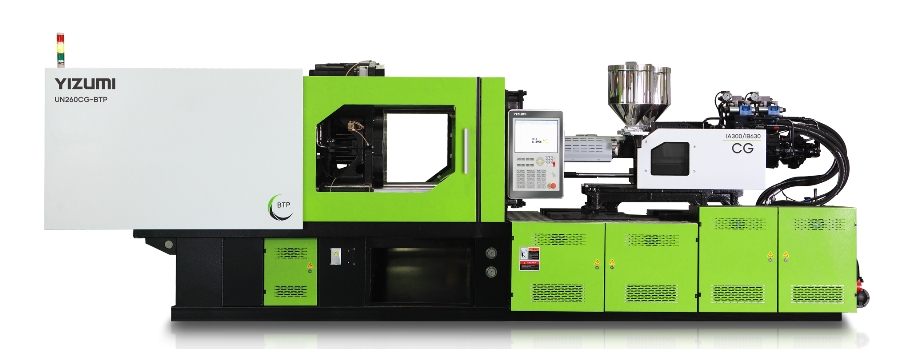

Ensuring the continuous operation of plastics moulding machines is essential for manufacturers to meet production deadlines and maintain high levels of efficiency. Unwanted stoppages due to mechanical failures or maintenance oversights can have a significant impact on productivity, leading to delays and increased costs. Establishing a robust preventive maintenance routine not only reduces the risk of downtime but also prolongs the life of the machine and ensures better product quality. In this article, we will delve into maintenance strategies that help manufacturers keep their injection machines running smoothly, and how YIZUMI's CG-P Series can support these efforts. To stay competitive, manufacturers must ensure that their injection machines are consistently operational. This means having reliable plastics moulding machines with preventive maintenance routines in place. Downtime is costly, and the longer a machine stays offline, the more it affects production schedules. A well-maintained machine not only reduces the risk of unexpected breakdowns but also extends its lifespan, making it a more cost-effective investment. One key to avoiding unscheduled stoppages is ensuring that preventive maintenance is performed regularly by both machine operators and maintenance teams.

Reasons for Unwanted Stoppage

Unwanted stoppages in injection machine for plastic processes often occur due to several reasons.

l Wear and Tear: Over time, essential components like screws, barrels, and clamping units experience wear, leading to performance issues.

l Temperature Fluctuations: Machines require optimal temperature control for effective operations. Any failure in heating or cooling systems can lead to production errors and machine stoppage.

l Lubrication Problems: Inadequate or improper lubrication can cause excessive friction and part failures, particularly in the clamping and injection units.

l Electrical Failures: Problems with wiring, circuit boards, or power supplies can lead to sudden shutdowns or malfunctions.

Addressing these common causes through a consistent maintenance routine can significantly reduce unexpected downtime.

Preventive Maintenance Routine: Walk-Around Inspections for the Machine Operator

A key aspect of preventive maintenance for plastics moulding machines is the daily inspection routine performed by the machine operator. These quick checks help identify early warning signs of potential issues before they become serious problems.

Operator's Walk-Around Inspection Checklist:

l Check for any unusual noises during machine operation.

l Monitor hydraulic oil levels and inspect for any leaks.

l Ensure that the machine's temperature controls are functioning correctly.

l Verify that the mold area is free of debris or product residue.

l Inspect hoses, belts, and connectors for signs of wear or damage.

l Lubricate moving parts as recommended by the manufacturer.

These inspections, when performed consistently, help to maintain the overall health of the injection machine for plastic production lines.

Preventive Maintenance Routine: Walk-Around Inspections for the Maintenance Team

While operators perform daily checks, the maintenance team should conduct more in-depth inspections on a weekly or monthly basis. This team should focus on the mechanical, electrical, and hydraulic systems of the injection machines.

Maintenance Team Inspection Checklist:

l Inspect screws, barrels, and clamping units for wear and tear.

l Test the electrical control system for any irregularities or faulty connections.

l Clean and recalibrate temperature sensors and heating elements.

l Check for proper alignment of the mold and clamping unit.

l Inspect the hydraulic system for leaks or pressure loss and replace filters as needed.

l Perform a detailed lubrication check and replace parts that show excessive wear.

These detailed inspections by the maintenance team ensure that plastics moulding machines continue operating at peak efficiency, reducing the likelihood of long-term damage.

Preventive Maintenance Routine: YIZUMI Service Support

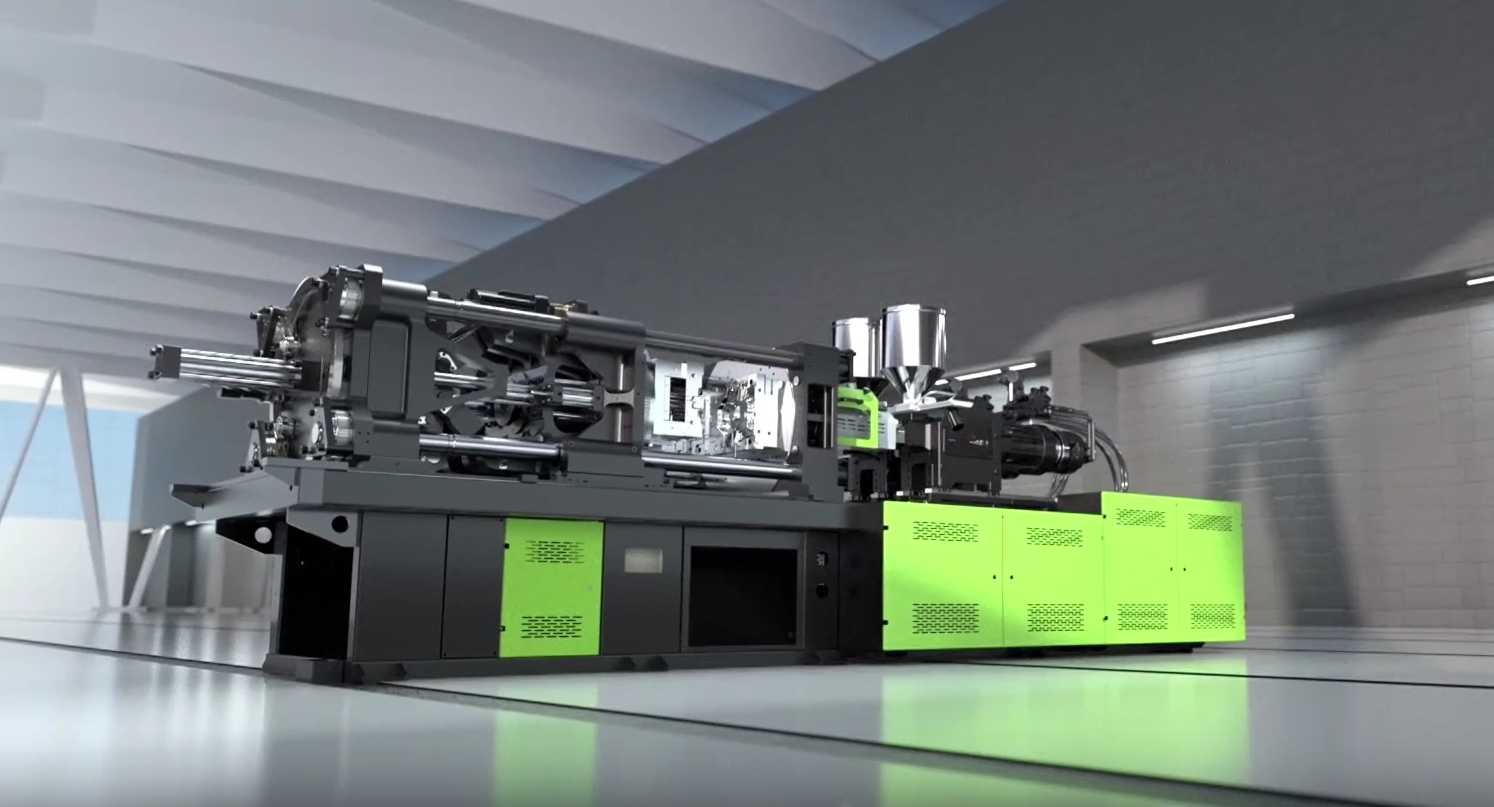

YIZUMI?understands the importance of keeping machines running without interruption. Their CG-P Series?High-end Multi-component Injection Moulding Machine is designed with easy maintenance in mind. With features like remote online monitoring of production and advanced control systems, manufacturers can monitor machine performance in real time. The?CG-P Series?also comes with customizable maintenance schedules and integrated control for auxiliary equipment, making it easier to track wear and identify potential issues before they cause a breakdown.

YIZUMI offers technical support and on-site service to assist manufacturers in maintaining their machines and reducing downtime. This service includes routine inspections, emergency repairs, and guidance on how to properly maintain the injection machines for peak performance.

Preventive Maintenance Made Easy with YIZUMI

The YIZUMI CG-P Series High-end Multi-component Injection Moulding Machine?offers several features that make maintenance easier and more efficient:

-Digital Closed-Loop Positioning Control: Ensures precise movements and minimizes wear on mechanical parts.

-Magnetically Levitated Turntable Technology: Reduces friction and wear, extending the life of the turntable and related components.

-Modular Injection Units: Allows for easy customization and maintenance, as individual components can be serviced without affecting the entire system.

-Remote Monitoring: Provides real-time data on machine performance, allowing manufacturers to stay ahead of any potential issues.

These features ensure that manufacturers can perform preventive maintenance on time, keeping their plastics moulding machines operating efficiently.

TIP: The Most Overlooked Preventive Maintenance Methods

While routine checks are important, there are a few preventive maintenance methods that are often overlooked:

-Cleaning the Cooling System: Keeping the cooling system free of debris and scaling is crucial for maintaining consistent temperatures.

-Regularly Updating Software: Modern injection machines use advanced control systems. Ensuring that the software is up-to-date can prevent malfunctions.

-Documenting Maintenance Activities: Keeping a detailed log of maintenance activities helps track wear patterns and predict future failures.

By implementing these overlooked methods, manufacturers can further extend the life of their plastics moulding machines and reduce downtime.

Conclusion

To keep production on-time, all the time, preventive maintenance is a must for injection machines. By implementing regular walk-around inspections and leveraging the advanced features of machines like YIZUMI's CG-P Series, manufacturers can reduce downtime and improve the overall efficiency of their production lines.

For more information about YIZUMI's high-performance plastics moulding machines?and their maintenance solutions, visit our website?today.