Top 5 Innovations in Die Casting Technology: How YIZUMI is Leading the Way

Abstract:

Discover the top 5 innovations in die casting technology that are revolutionizing manufacturing. Learn how our advanced die casting solutions enhance productivity and quality.

Die casting technology has undergone significant advancements in recent years, driving efficiency, precision, and sustainability in manufacturing. As industries demand higher quality and faster production, innovative die casting solutions have become crucial for maintaining competitiveness. YIZUMI, a leader in die casting technology, has pioneered groundbreaking advancements with its LEAP Series Die Casting Machine, setting new standards for performance, reliability, and energy efficiency.

Why Innovation Matters in Manufacturing

Manufacturing is at the heart of industrial progress, and innovation plays a vital role in optimizing production processes. In die casting, technological improvements directly impact cost efficiency, material utilization, and product quality. The latest developments in die casting technology focus on:

· Enhancing production speed?to meet growing demand.

· Reducing energy consumption?for sustainable manufacturing.

· Increasing precision and consistency?to minimize defects.

· Integrating intelligent control systems?for real-time monitoring and optimization.

· Improving overall equipment effectiveness (OEE)?to maximize operational efficiency.

By embracing innovative die casting solutions, manufacturers can achieve higher productivity, lower costs, and superior product quality, ensuring long-term success in the industry.

Top 5 Innovations in Die Casting Technology

1. Real-Time Closed-Loop Injection Control

One of the most significant advancements in die casting technology is the introduction of real-time closed-loop injection systems. This innovation allows for precise control of injection parameters, ensuring:

· Consistent shot quality, reducing defects and material waste.

· Real-time adjustments, compensating for variations in temperature and material flow.

· Higher repeatability, enabling mass production with minimal variation.

2. Intelligent Digital Control Systems

The integration of digital control systems has transformed the way die casting machines operate. Modern control platforms offer:

· User-friendly HMI (Human-Machine Interface)?for simplified machine operation.

· AI-driven algorithms?that optimize cycle times and reduce downtime.

· Predictive maintenance features?that prevent unexpected breakdowns.

These intelligent systems enhance automation, making die casting more efficient and cost-effective.

3. High-Efficiency Energy-Saving Technology

As sustainability becomes a priority in manufacturing, die casting technology has evolved to incorporate energy-saving solutions. The latest innovations include:

· Servo-driven pump units?that optimize energy use.

· Hydraulic systems with advanced efficiency algorithms?to minimize power consumption.

· Eco-friendly cooling systems?that reduce waste heat and improve overall performance.

With these improvements, manufacturers can lower operational costs while reducing their environmental impact.

4. Automated Die Handling and Clamping Systems

Automation in die casting extends beyond the injection process. Advanced die opening and closing systems now offer:

· Accurate control of die positioning?with repeatability up to ±1mm.

· Automatic clamping force detection, ensuring consistent part quality.

· Quick die change systems, reducing downtime and increasing production flexibility.

These innovations streamline manufacturing processes, improving productivity and reducing manual labor requirements.

5. Self-Learning Injection Technology

Machine learning has started to revolutionize die casting by enabling self-learning injection systems. These systems:

· Analyze past production data?to optimize future casting processes.

· Automatically adjust injection speed and pressure?for enhanced consistency.

· Reduce human intervention, allowing operators to focus on quality control and efficiency improvements.

By integrating AI-driven technologies, die casting machines can continuously improve their performance, leading to higher-quality products and reduced waste.

YIZUMI's Contribution to Die Casting Innovation

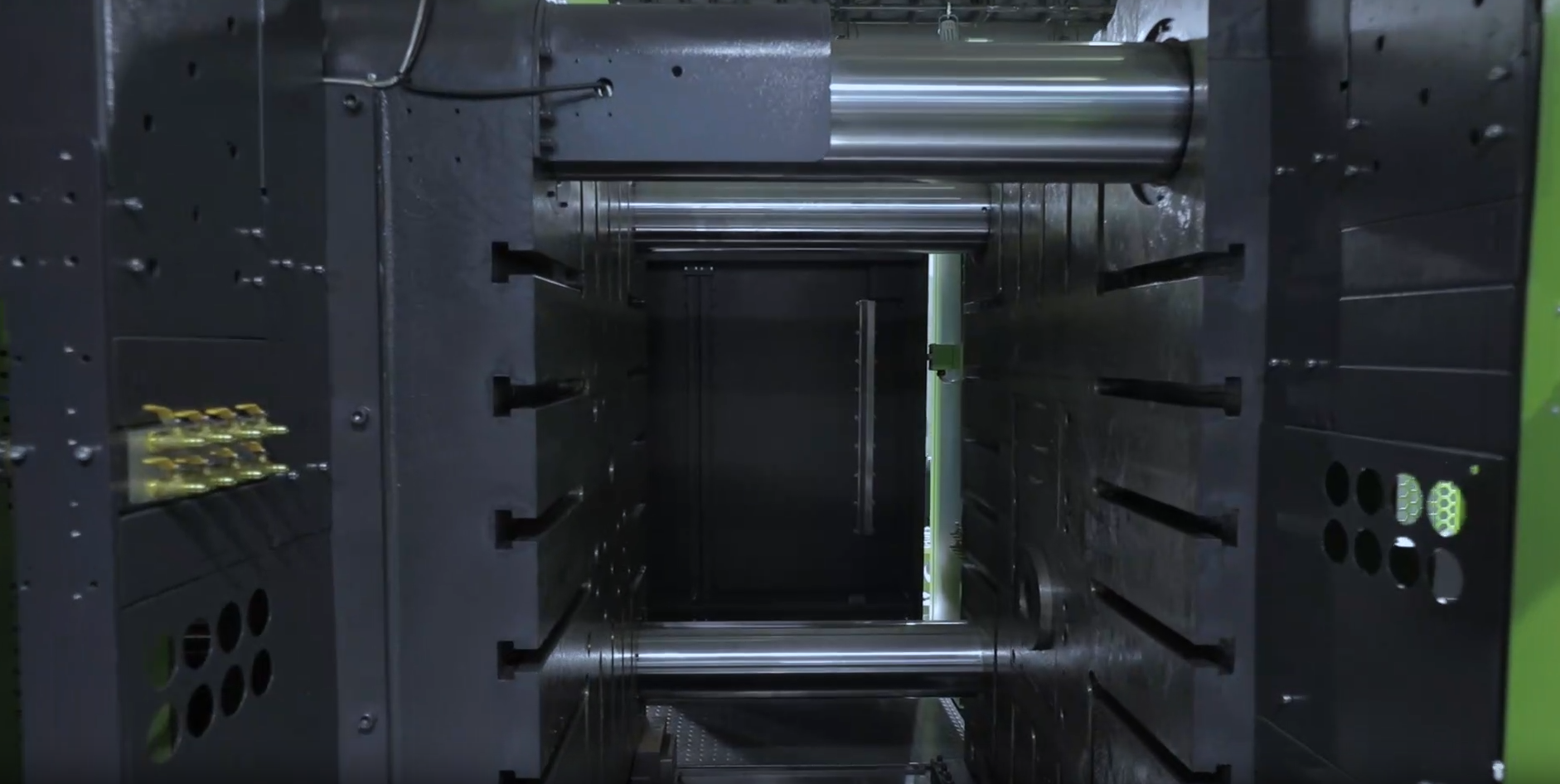

At YIZUMI, we are committed to pushing the boundaries of die casting technology. Our LEAP Series Die Casting Machine?is a prime example of how innovation can transform manufacturing. This machine integrates cutting-edge features to deliver superior performance, precision, and energy efficiency.

LEAP Series Die Casting Machine: Redefining Industry Standards

Yi-Cast Real-Time Closed-Loop Injection System

· Ensures each injection is performed with unmatched precision and quality assurance.

· Automatically adjusts speed and pressure, eliminating guesswork and improving consistency.

ORCA Control System: The Future of Digital Die Casting

· Features an intuitive 24-inch touch panel?for seamless operation.

· Utilizes advanced control algorithms?to optimize injection and clamping processes.

· Enables full digitalization, enhancing automation and traceability.

Energy-Efficient Yi-Drive Pump Unit

· Incorporates servo + feed technology, reducing energy consumption by up to 40%.

· Enhances overall equipment effectiveness (OEE), maximizing productivity.

Intelligent Die Opening and Closing System

· Ensures highly precise control of die movement, minimizing misalignment.

· Offers automatic clamping force detection and die height adjustment, improving process stability.

By integrating these advanced technologies, YIZUMI die casting machines help manufacturers achieve higher efficiency, reduced costs, and improved product quality.

FAQs

1. What makes YIZUMI's LEAP Series Die Casting Machine different from traditional machines?

YIZUMI's LEAP Series features real-time closed-loop injection control, intelligent digital systems, and energy-efficient pump technology. These advancements result in higher precision, reduced energy consumption, and improved repeatability compared to traditional die casting machines.

2. How does real-time injection control improve die casting quality?

Real-time closed-loop control ensures that each shot maintains consistent pressure and speed, minimizing defects and material waste. This leads to higher-quality castings and improved production efficiency.

3. Can YIZUMI's die casting machines be integrated into existing production lines?

Yes, our machines are designed for seamless integration with modern manufacturing systems. The ORCA control system allows for easy automation, real-time monitoring, and smart factory compatibility.

4. What industries benefit most from YIZUMI's die casting technology?

Our die casting solutions are widely used in automotive, aerospace, electronics, and industrial equipment?manufacturing. The precision and efficiency of our machines make them ideal for producing high-performance components in these industries.

5. How does YIZUMI ensure sustainability in die casting?

We prioritize energy efficiency with our servo-driven pump units, reducing power consumption by up to 40%. Additionally, our intelligent control systems optimize production processes to minimize waste and resource use.

Conclusion

The die casting industry is evolving rapidly, with innovations focused on precision, efficiency, and sustainability. YIZUMI's LEAP Series Die Casting Machine represents the future of manufacturing, integrating real-time closed-loop control, AI-driven optimization, and energy-efficient technology. As we continue to push the boundaries of die casting technology, our solutions empower manufacturers to achieve superior quality, increased productivity, and sustainable operations.

For businesses looking to stay ahead in the competitive world of manufacturing, YIZUMI die casting machines offer the perfect combination of innovation and reliability.

Contact YIZUMI?today to learn more about how our advanced die casting solutions can transform your production process.