Unlocking Manufacturing Potential How 3D Printing is Revolutionizing Production Floors

Abstract:

Discover how 3D printing is transforming manufacturing with enhanced efficiency, cost savings, and new possibilities. Explore YIZUMI’s industrial 3D printing solutions.

The Evolving Landscape of Manufacturing and the Rise of 3D Printing

The manufacturing industry is undergoing a profound transformation, driven by advancements in 3D printing?technology. As industrial demands shift towards greater efficiency, customization, and cost-effectiveness, industrial 3D printing?has emerged as a game-changer. Traditional manufacturing methods, while effective, often involve high material waste, extended lead times, and costly tooling. 3D printing?overcomes these limitations by enabling direct digital fabrication, reducing dependency on molds and minimizing material waste.

Over the past decade, 3D printing?has evolved from a prototyping tool to an integral part of large-scale manufacturing. Companies across various industries—automotive, aerospace, healthcare, and consumer goods—are integrating 3D printing solutions?into their production workflows to streamline operations and unlock new possibilities.

Deep Dive into Different 3D Printing Methods

To fully understand the impact of industrial 3D printing, it is essential to explore the different printing technologies available today. Each method offers unique advantages and applications:

Fused Deposition Modeling (FDM)

FDM is one of the most widely used 3D printing methods in both industrial and personal applications. This technique works by extruding thermoplastic filaments through a heated nozzle, which deposits the material layer by layer to gradually build up the final part or object. The process allows for precise control over the shape and structure of the printed object, making it ideal for creating complex geometries. Due to its affordability and ease of use, FDM is particularly popular in prototyping, where rapid iterations and testing are essential. Additionally, it is also used for low-cost manufacturing, especially in the production of small batches or custom components, where traditional manufacturing methods might be too expensive or time-consuming.

Stereolithography (SLA)

SLA utilizes a liquid resin that is hardened by a UV laser. This method is known for its high precision and smooth surface finish, making it ideal for detailed prototypes and medical applications.

Selective Laser Sintering (SLS)

SLS employs a high-powered laser to fuse powdered materials, creating durable and complex parts. This method is often used for functional prototypes and low-volume production.

Metal 3D Printing

For industries requiring high-strength components, metal 3D printing?methods such as Direct Metal Laser Sintering (DMLS) and Electron Beam Melting (EBM) provide excellent mechanical properties and design flexibility.

Applications in Manufacturing

The adoption of 3D printing?in manufacturing is rapidly expanding, with key applications including:

l Rapid Prototyping:?Manufacturers can develop prototypes quickly, testing and refining designs without costly tooling.

l Tooling and Fixtures: 3D printing?enables the production of lightweight, customized tools and jigs, enhancing efficiency on the production floor.

l Low-Volume Manufacturing:?Small-batch production is now cost-effective, allowing companies to produce custom parts without large-scale investments.

l Spare Parts Production:?Instead of maintaining vast inventories, manufacturers can use industrial 3D printing?to create replacement parts on demand.

l Complex Geometries: 3D printing?enables the production of intricate designs that would be impossible with traditional methods, reducing weight while maintaining strength.

YIZUMI's 3D Printing Solutions

As a leader in advanced manufacturing solutions, YIZUMI?has developed cutting-edge 3D printing solutions?that address the challenges of industrial production. Our SpaceA S-Line Industrial Pellet 3D Printing?system offers a revolutionary approach to industrial 3D printing, providing unparalleled efficiency, material flexibility, and production scalability.

Lower Cost with General Injection Molding Materials

Unlike traditional 3D printing?methods that require expensive proprietary materials, YIZUMI’s?SpaceA S-Line can utilize standard thermoplastic pellets, significantly reducing production costs while maintaining high-quality output.

Superior Surface Quality and Dimensional Accuracy

With an integrated CNC machining automation?process and insert molding technology, our solution ensures excellent surface finish and precise dimensional accuracy, essential for industrial applications.

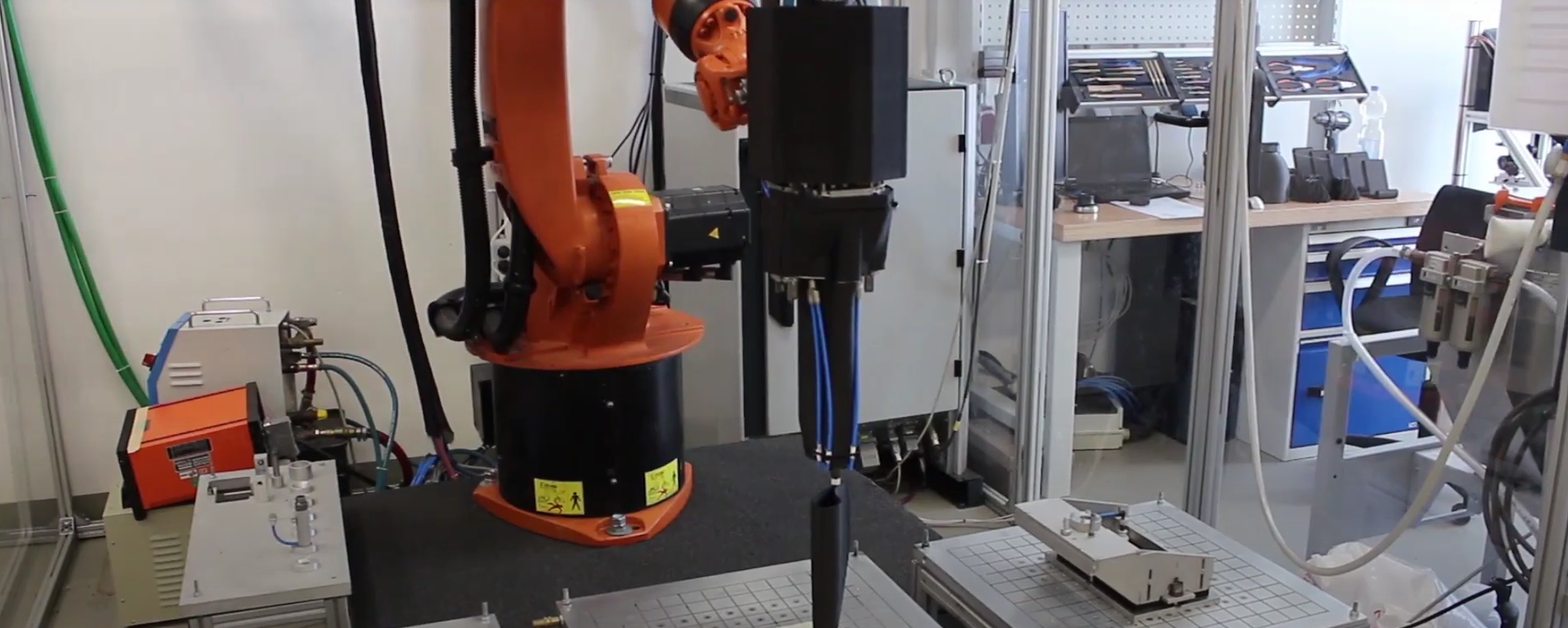

3D Reinforcement with Robotic Precision

The SpaceA S-Line employs a 6-axis robotic system, enabling complex product structures?with enhanced mechanical strength. This innovation expands the possibilities of industrial 3D printing, making it suitable for structural applications and lightweight component manufacturing.

High Output for Large-Scale Manufacturing

Capable of processing over 500g/h, the SpaceA S-Line?meets the demands of high-volume production, bridging the gap between traditional manufacturing and 3D printing.

Modular Design for Seamless Integration

YIZUMI's modular system?allows for easy integration with existing manufacturing processes, including injection molding?and image recognition technologies. This adaptability ensures that manufacturers can implement YIZUMI’s 3D printing solution?without overhauling their production lines.

Advanced Control and Automation

Equipped with an ergonomic human-machine interface, YIZUMI’s?SpaceA S-Line provides real-time monitoring, precise movement control, and an intuitive operation experience, enhancing efficiency and reducing human error.

By leveraging YIZUMI's industrial 3D printing?expertise, manufacturers can achieve new levels of efficiency, cost reduction, and production flexibility, ensuring they stay ahead in a rapidly evolving market.

FAQ

Q1: How does YIZUMI's 3D printing solution compare to traditional 3D printing?

A: YIZUMI’s SpaceA S-Line?differs from conventional 3D printing?by utilizing thermoplastic pellets instead of filaments or resins. This allows for lower material costs, higher throughput, and greater material selection.

Q2: Is the SpaceA S-Line suitable for large-scale manufacturing?

A: Yes. With a high output rate (>500g/h) and seamless integration capabilities, our solution is ideal for both prototyping and industrial-scale production.

Q3: What industries can benefit from YIZUMI's 3D printing technology?

A: Industries such as automotive, aerospace, consumer goods, and healthcare can leverage our industrial 3D printing?technology to streamline manufacturing processes, reduce costs, and enhance product innovation.

Q4: How does YIZUMI ensure the quality and precision of printed parts?

A: Our 3D printing?system integrates CNC machining automation?and insert molding technology?to deliver high surface quality and dimensional accuracy, making it suitable for industrial applications.

Conclusion

3D printing?is revolutionizing the manufacturing industry, offering unparalleled flexibility, efficiency, and cost savings. As the technology advances, industrial manufacturers must adopt innovative solutions to stay competitive.

At YIZUMI, we are committed to providing industry-leading 3D printing solutions?that bridge the gap between traditional manufacturing and the future of digital fabrication. With our SpaceA S-Line Industrial Pellet 3D Printing?system, manufacturers can achieve lower costs, higher output, and greater precision, unlocking new opportunities for innovation and efficiency.

For those looking to enhance their production capabilities with cutting-edge industrial 3D printing, YIZUMI?stands ready to deliver the technology and expertise needed to drive the future of manufacturing.