3D Printing: A Sustainable Solution for Modern Manufacturing

Abstract:

How 3D printing supports sustainable manufacturing and how YIZUMI 3D printing solution boosts environmental responsibility.

The Growing Focus on Environmentally Responsible Manufacturing

In the face of climate change, resource scarcity, and increasing environmental regulations, sustainability has become a strategic imperative in the manufacturing industry. Companies across all sectors are searching for ways to reduce their carbon footprint, cut material waste, and create more circular production models.

3D printing, or additive manufacturing, is playing a central role in this transformation. Unlike traditional subtractive manufacturing methods that remove material from a larger block, 3D printing?builds objects layer by layer, using only the amount of material required. This approach not only enables design flexibility but also opens the door to sustainable production processes?that align with both economic and environmental goals.

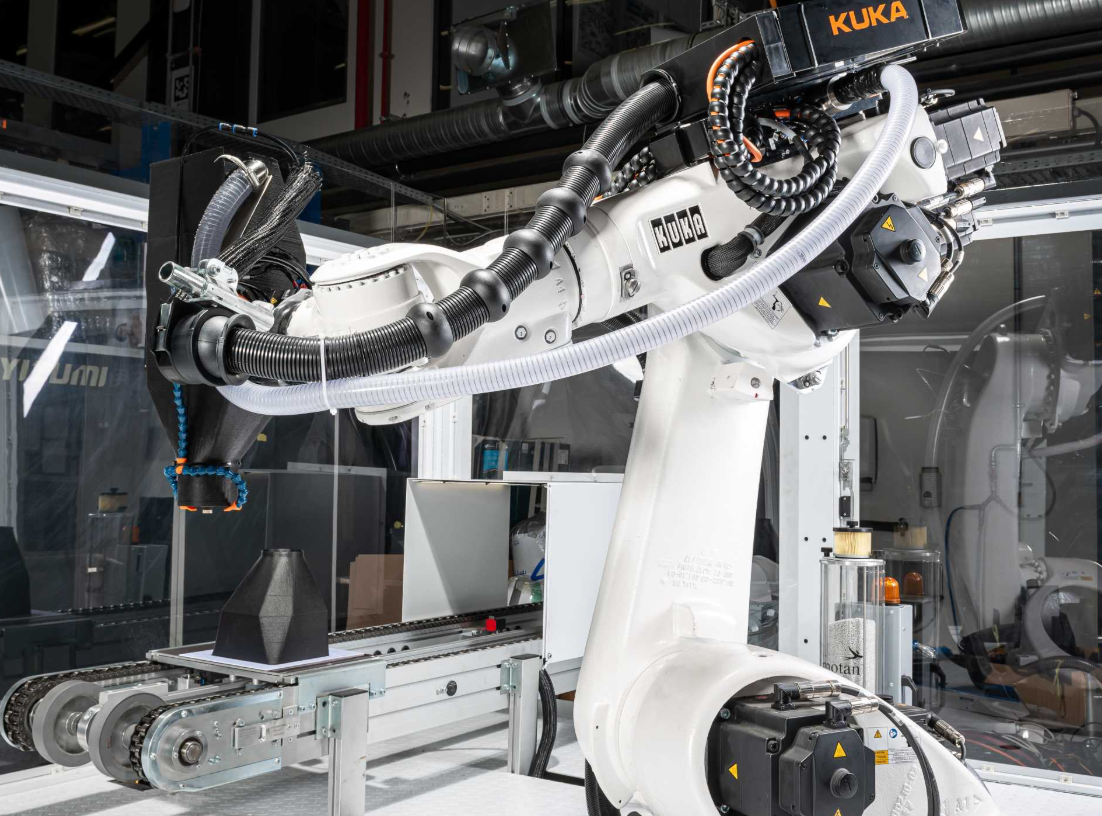

As a leading provider of molding and forming technologies, YIZUMI?integrates sustainability into the very core of our solutions. Our YIZUMI 3D printing solution, especially the SpaceA B-Line Industrial Pellet 3D Printing system, empowers manufacturers to improve efficiency, reduce waste, and transition toward greener practices.

Reducing Waste and Optimizing Material Usage

One of the biggest environmental concerns in traditional manufacturing is material waste. Whether in machining, injection molding, or stamping, a significant percentage of raw material is lost during processing—ending up as unusable scraps or requiring extensive rework.

With industrial 3D printing, manufacturers gain precise control over material usage. Since parts are built layer by layer directly from digital designs, there’s no need to cut away excess material. This leads to:

l Up to 90% material savings?compared to subtractive methods

l Lower production waste and post-processing requirements

l Improved yields from high-cost or specialty materials

Furthermore, 3D printing?encourages the use of recycled or bio-based materials. Many pellet-fed systems, including YIZUMI’s, can handle reprocessed thermoplastics and environmentally friendly composites, making the circular economy a practical reality for manufacturers.

Minimizing Transportation and Supply Chain Emissions

Traditional manufacturing often depends on global supply chains involving multiple tiers of suppliers, extended logistics routes, and high inventory levels. This complexity results in significant greenhouse gas emissions from transportation and warehousing activities.

3D printing?offers a powerful alternative by localizing production. With the ability to produce end-use parts on-site or near end-users, companies can:

l Reduce reliance on overseas suppliers

l Minimize transportation emissions

l Lower the need for warehousing and inventory holding

This on-demand manufacturing model not only improves sustainability but also enhances supply chain resilience—an essential advantage in a world of ongoing geopolitical disruptions and rising freight costs.

Sustainable Practices in 3D Printing

Sustainability in 3D printing?extends beyond waste reduction and local production. It also touches product lifecycle management, design optimization, and energy use. By enabling complex geometries and functional integration, 3D printing?allows for:

l Lighter parts, especially in the automotive and aerospace sectors, leading to fuel savings in the final product

l Fewer components per assembly, reducing resource consumption and simplifying repair and recycling

l Mass customization, eliminating overproduction and enabling just-in-time delivery of tailored goods

Additionally, industrial 3D printing?reduces tooling requirements. Traditional tools and molds, often made from high-energy-consuming materials like steel or aluminum, can be bypassed entirely. This not only cuts emissions but also reduces the environmental impact of tooling manufacturing and disposal.

Energy-Saving and Environmental-Friendly Features of YIZUMI 3D Printing Equipment

As part of our commitment to sustainable innovation, YIZUMI?has engineered our SpaceA B-Line Industrial Pellet 3D Printing?system?to support energy-efficient, low-impact manufacturing.

Modular Design with Wide Customization

The SpaceA B-Line?offers manufacturers flexible configuration options, including robotic arms from 1.6 to 3.9 meters, two extruder types, and various platform sizes. This adaptability enables efficient production tailored to different industries, from household goods to automotive parts, without the waste of one-size-fits-all equipment.

Intelligent Control Panel

Our Beckhoff-based HMI control panel?presents a harmonious human-machine interface, allowing operators to manage every stage of production with precision. The intuitive interface reduces training time, cuts energy consumption through smarter operations, and ensures consistent performance.

Robotic Precision for Reduced Rework

Our robotic system achieves a positioning repeatability error of ≤0.05mm, ensuring accuracy and stability. This precision minimizes print defects and rework, reducing material waste and improving overall resource efficiency.

Collaboration with Recozy and Biofibre

We are proud to collaborate with partners like Recozy and Biofibre, incorporating bio-based and recycled materials into our production ecosystem. This aligns with global sustainability goals and supports manufacturers looking to reduce their environmental impact through responsible material sourcing.

With YIZUMI 3D printing solution, we offer more than a machine—we offer a gateway to cleaner, smarter, and more sustainable manufacturing.

FAQ: Sustainable Manufacturing with Industrial 3D Printing

Q1: Can 3D printing really make a significant impact on sustainability?

Yes. By reducing material waste, minimizing transportation needs, and enabling local production, 3D printing?delivers meaningful environmental benefits. When combined with bio-based materials, its impact is even greater.

Q2: How does YIZUMI’s SpaceA B-Line support sustainability?

Our SpaceA B-Line?system uses energy-efficient robotics, supports recycled and bio-based pellets, and enables manufacturers to scale operations with less waste and fewer emissions. It reflects our broader expertise in sustainable equipment solutions drawn from injection molding, rubber, and die casting technologies.

Q3: Is pellet-based 3D printing more sustainable than filament-based?

Absolutely. Pellets are typically cheaper, more available in recycled form, and can be processed in larger volumes. This makes pellet 3D printing?more suitable for industrial, sustainable manufacturing.

Q4: What industries benefit most from YIZUMI’s 3D printing solution?

Industries such as automotive, home appliances, furniture, and prototyping are already benefiting. Our flexible setup allows companies to adopt additive manufacturing at different scales without compromising on quality or efficiency.

Q5: How does YIZUMI ensure consistent performance in sustainable 3D printing?

We combine deep engineering expertise, smart automation, and robust materials handling with an integrated approach to service. Our clients don’t just get equipment—they get a complete forming equipment solution?aligned with their green production goals.

Shaping a Greener Future with YIZUMI 3D Printing

Sustainability is not just a trend—it’s a necessity for the manufacturing industry. As environmental regulations tighten and consumer awareness grows, businesses must evolve their production methods. 3D printing?provides a clear, scalable path toward that transformation.

With our YIZUMI 3D printing solution, specifically the SpaceA B-Line Industrial Pellet 3D Printing system, we help manufacturers make this shift confidently and efficiently. Backed by our strong foundation in injection molding, rubber, and die casting, we provide complete forming solutions that are not only high-performance but also aligned with environmental responsibility.

From reducing waste and energy use to empowering smart, localized production, we are committed to driving a sustainable manufacturing future—layer by layer.

Now is the time to build better. And with YIZUMI, building greener is within reach.