How 3D Printing is Accelerating Manufacturing Processes

Abstract:

Discover how industrial 3D printing is reshaping manufacturing and how YIZUMI 3D printing solution boosts speed and efficiency.

The Revolution Behind Modern Manufacturing

In today’s competitive industrial landscape, manufacturers are under pressure to produce faster, cheaper, and more sustainably than ever before. Enter 3D printing, a game-changing technology that’s doing far more than just prototyping. It’s transforming manufacturing from the ground up—making it smarter, more flexible, and more responsive to the demands of modern markets.

For manufacturers in sectors ranging from automotive to aerospace and construction, industrial 3D printing?is enabling unprecedented production agility. The ability to print end-use parts directly from digital models not only cuts down lead times but also reduces tooling costs and material waste.

At the forefront of this transformation is YIZUMI 3D printing solution, combining our legacy of excellence in injection molding, rubber, and die casting with forward-thinking additive manufacturing. In this article, we explore how 3D printing is revolutionizing production lines and how our SpaceA C-Line Industrial Pellet 3D Printing system?is enabling manufacturers to unlock the next level of performance.

The Rise of Industrial 3D Printing

From Prototyping to Full-Scale Production

While 3D printing?was once viewed primarily as a rapid prototyping tool, it has now matured into a reliable method for full-scale manufacturing. With advancements in material science, printer speed, and design software, companies can now produce functional, load-bearing parts?that rival those made using traditional subtractive or injection-based techniques.

Industries such as aerospace and medical devices are leveraging industrial 3D printing?to customize parts at scale, while reducing weight and enhancing part complexity. This is especially beneficial for low-volume, high-mix production scenarios where traditional tooling becomes a time- and cost-intensive bottleneck.

Cost Efficiency and On-Demand Flexibility

Unlike traditional manufacturing that relies on extensive molds, fixtures, and pre-planned production runs, 3D printing?allows manufacturers to print on-demand, cutting storage and inventory costs. Moreover, it dramatically reduces material wastage because it builds parts layer by layer—using only what’s necessary.

Companies adopting industrial 3D printing?are not just making things faster—they’re also cutting down operational expenses, shortening time-to-market, and becoming more responsive to design changes or urgent production needs.

How 3D Printing Enhances the Manufacturing Workflow

Design Freedom and Product Customization

Additive manufacturing enables engineers to design without constraints. Internal channels, lattice structures, lightweight geometries—everything becomes possible. With 3D printing, parts that used to require multiple assemblies can now be printed as a single, integrated component, reducing weak points and simplifying logistics.

In industries such as automotive or construction machinery, where custom parts may be needed for specialized applications, 3D printing?enables mass customization?without the need to retool the production line.

Accelerated Product Development Cycles

By eliminating the delay of mold creation, 3D printing?empowers companies to test multiple design iterations rapidly. Teams can get real-world feedback faster, make refinements instantly, and launch products with more confidence. The result is a dramatic improvement in innovation cycles—what once took months now takes days.

This agility is not only valuable for startups or niche manufacturers but also for large-scale players responding to dynamic markets or urgent client demands.

Bridging Digital and Physical Manufacturing with YIZUMI

At YIZUMI, we believe in pushing the boundaries of what’s possible with manufacturing. Our deep experience in injection molding, rubber, and die casting core technologies?has given us a clear understanding of production precision and material behavior. We’ve taken this expertise and extended it to a new frontier—industrial 3D printing.

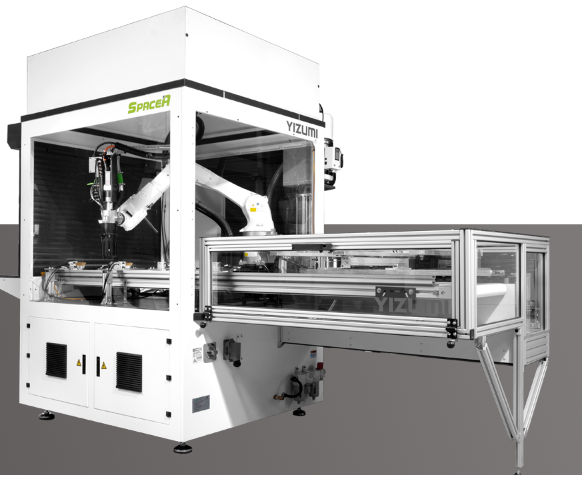

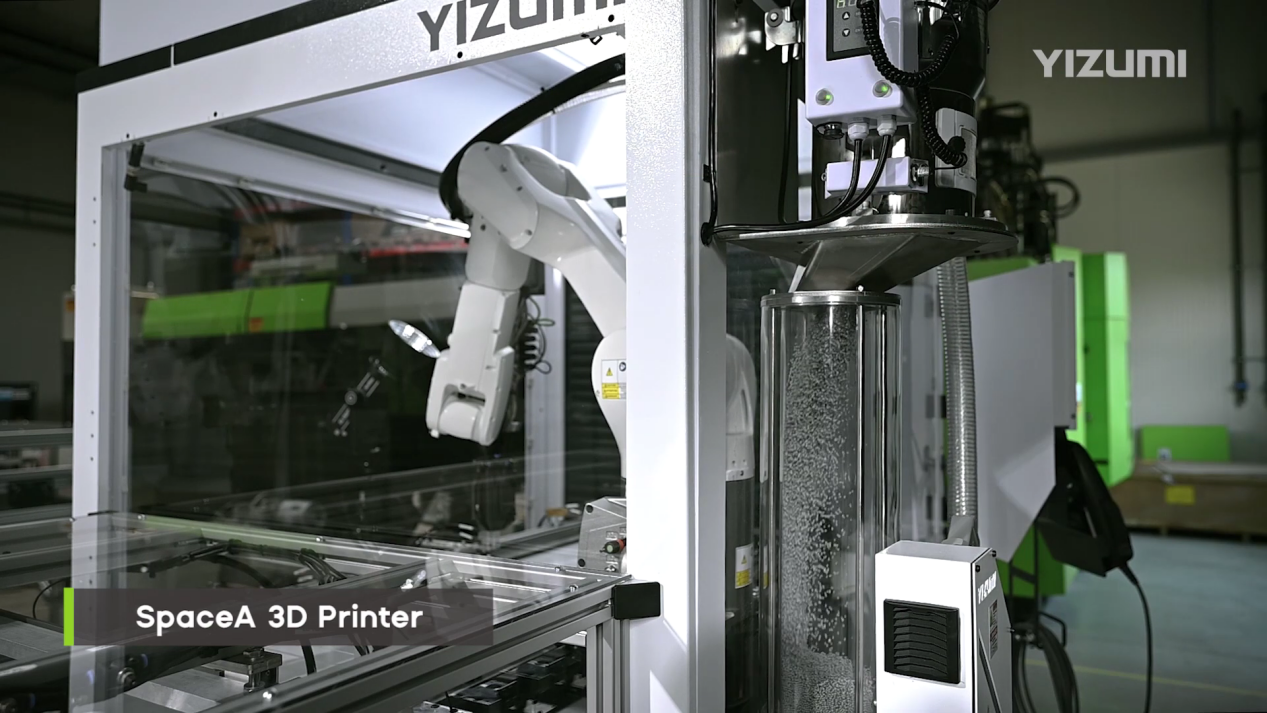

Introducing our SpaceA C-Line Industrial Pellet 3D Printing?system, designed to meet the needs of manufacturers who demand speed, reliability, and customization. This system represents the perfect bridge between traditional production and digital manufacturing.

YIZUMI SpaceA C-Line: Innovation in Every Layer

Our YIZUMI 3D printing solution?combines performance, intelligence, and flexibility—empowering industries to reshape how they design and build.

Lightweight, High-Performance Extruder

The SpaceA C-Line’s extruder?features a coaxial feeding section with an integrated storage unit, designed for minimal weight—only 6.5kg—and maximum adaptability. This allows for smooth, uninterrupted printing?across a variety of industrial thermoplastic pellets. The extruder design supports high flow rates and continuous operation for extended production runs.

Robotic Precision and Accuracy

Precision is the heart of quality in 3D printing. Our robotic arm?delivers exceptional positioning repeatability ≤0.05mm, ensuring dimensional accuracy and structural integrity of printed parts. Whether you're producing complex tooling components or custom automotive brackets, the system provides flawless layer consistency?with excellent stability.

Intelligent, User-Centric Control Panel

An intuitive user interface is critical in streamlining operations. The SpaceA C-Line’s control panel?features an ergonomic human-machine interface, presenting comprehensive system data at a glance. Operators can adjust print parameters, monitor real-time performance, and switch between print jobs seamlessly—reducing setup times and ensuring optimal control throughout the process.

With YIZUMI 3D printing solution, we’re not just offering a machine—we’re delivering a complete additive manufacturing ecosystem?that integrates with your production line and your business goals.

Why Manufacturers Are Shifting to Pellet-Based 3D Printing

Pellet-fed systems like our SpaceA C-Line provide a major advantage: material flexibility and cost efficiency. Compared to filament-based 3D printing, pellet extrusion systems offer:

l Lower material costs

l Wider material compatibility, including recycled and composite materials

l Higher output rates, ideal for large-scale industrial components

This makes pellet 3D printing a sustainable and scalable solution?for forward-thinking manufacturers who want to reduce costs while increasing design flexibility.

Use Cases Across Industries

Automotive & Transportation

Produce lightweight vehicle components with custom geometries that reduce assembly and enhance performance. SpaceA’s speed and material flexibility are ideal for producing both prototypes and functional vehicle parts.

Construction & Infrastructure

Create molds, structural connectors, or decorative elements directly from digital blueprints. Pellet-based industrial 3D printing?allows for strong, weather-resistant parts?that meet rigorous site requirements.

Industrial Tooling & Fixtures

Reduce lead time for jigs, fixtures, and tooling with fast, repeatable printing. Adjust tool designs on the fly and integrate them into your workflows without costly delays or outsourcing.

FAQs About Industrial 3D Printing

Q1: How is industrial 3D printing different from desktop 3D printing?

Industrial 3D printing is designed for large-scale production with high-speed, high-strength outputs. It uses pellets or powders, not just filaments, and integrates with automation systems for seamless manufacturing.

Q2: Why choose a YIZUMI 3D printing solution over others?

We combine deep technical knowledge?in traditional molding with innovation in 3D printing. Our SpaceA C-Line?offers precision, flexibility, and energy-efficient operation, backed by our experience in complete forming equipment solutions.

Q3: Can this solution be customized for specific materials?

Yes. The SpaceA C-Line supports a wide range of thermoplastic materials, including composites, recycled pellets, and high-performance polymers.

Q4: Is the system suitable for low-volume or mass production?

It’s ideal for both. Whether you need quick prototypes or want to produce large functional parts, SpaceA C-Line’s scalable output?and flexibility make it the right fit.

Building the Future with YIZUMI 3D Printing

3D printing?is no longer just a buzzword—it’s a practical, high-impact solution?for the challenges modern manufacturers face. As production cycles shorten and customization becomes a competitive edge, industrial 3D printing?is proving to be an essential technology.

With YIZUMI 3D printing solution, including the powerful SpaceA C-Line, we empower manufacturers to produce smarter, faster, and with greater design freedom. Backed by our core competencies in injection molding, rubber, and die casting, we deliver more than just machines—we offer a complete forming equipment solution tailored to the future of manufacturing.

Embrace the shift. Let YIZUMI help you accelerate your production journey—layer by layer.