5 Tips for Two-platen Injection Molding Machine Operators

Abstract:

Running a Two-platen type isn't the same as running a traditional one. Here are a few tips for Two-platen Injection Molding Machine operators.

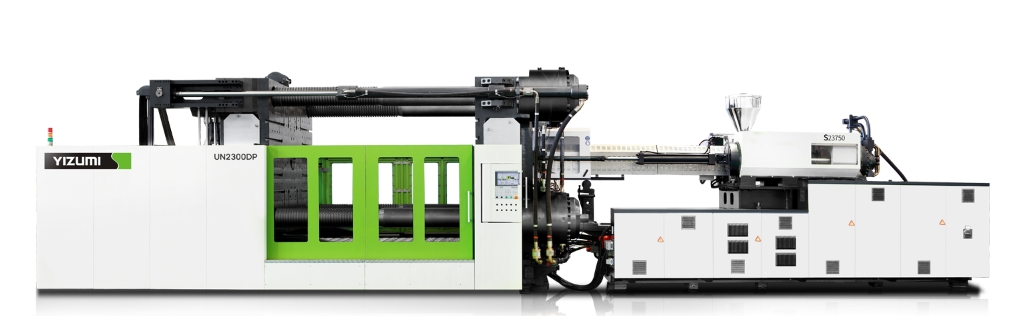

Operating a two-platen injection molding machine is a complex task that requires a deep understanding of both the machine and the materials used. For manufacturers looking to optimize their production processes, the YIZUMI DP Series Two-Platen Injection Molding Machine?offers advanced features and technology that enhance efficiency and precision. This article will outline five essential tips for operators, helping you navigate the intricacies of running these machines effectively. By following these guidelines, you can ensure high-quality output while maximizing the performance of your injection machine.

1. Know the Difference Between a Collet and a Guide Bushing

Understanding the components of your molding machine is crucial for successful operation. A collet is used to hold the tooling securely during the injection process, while a guide bushing provides a smooth path for the moving parts of the machine. When using the YIZUMI DP Series, recognizing the differences between these components can prevent misalignment and wear, which could lead to costly downtime.

Ensure that the collet and guide bushing are properly maintained. Regular checks and lubrication can extend their life and maintain the precision of the molding process. We emphasize that keeping these components in optimal condition is key to achieving the high standards associated with our injection machine.

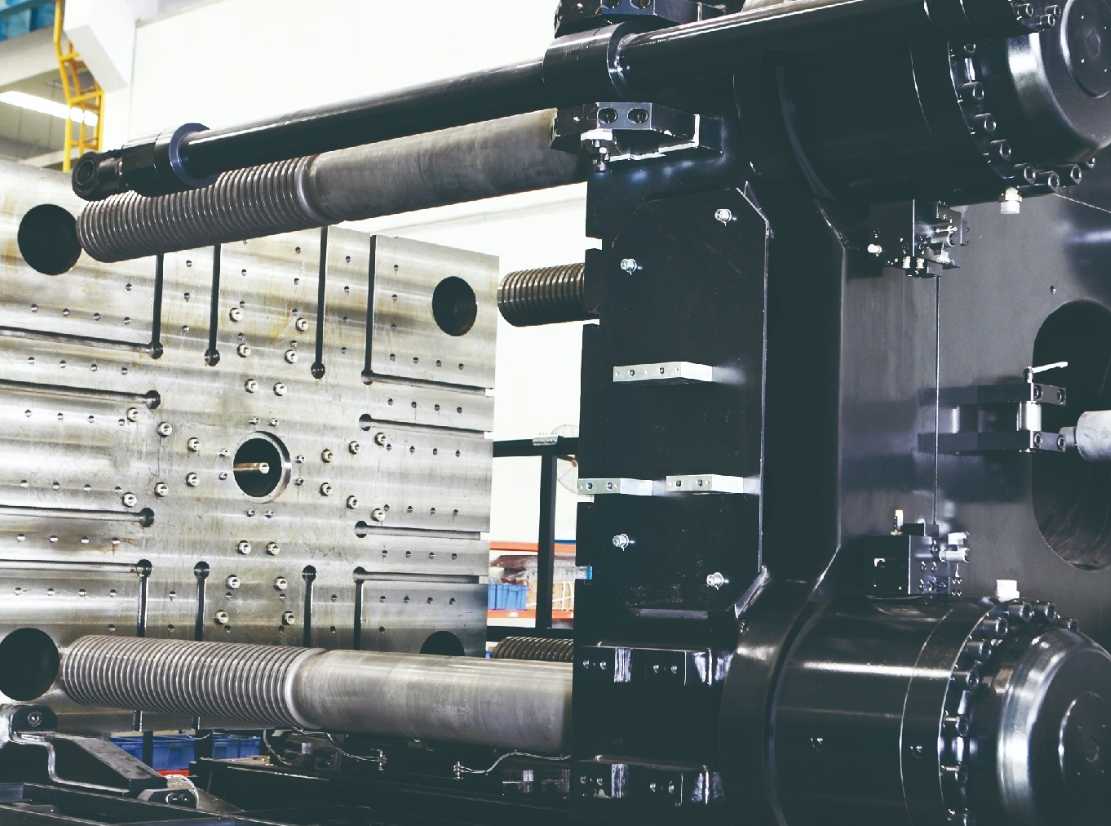

2. Measure Each Bar Before Installing

Before you begin any setup, it's essential to measure each tie bar carefully. This simple step can prevent alignment issues that can lead to poor quality parts. The YIZUMI DP Series features automatic tie bar retraction, but operators should still double-check the measurements to ensure the mold is seated correctly.

Using precise measurements not only enhances the machine's performance but also extends the life of your molds. An accurate installation means less wear and tear on the equipment and fewer defects in the final product. This attention to detail is a hallmark of effective injection machine operation and contributes to our commitment to quality as an injection machine manufacturer.

3. Take Care When Offsetting Tools

Offsetting tools can help accommodate various mold designs, but it must be done carefully. Incorrect offsets can lead to uneven pressure distribution and potentially damage the mold or the machine itself. When working with the YIZUMI DP Series, ensure that offsets are calculated precisely to maintain the integrity of both the mold and the injection machine.

Always refer to the machine's manual for guidance on how to make these adjustments safely. Our advanced systems are designed for flexibility, but they also require careful handling to maximize their benefits. By being meticulous in your approach, you will avoid unnecessary repairs and enhance production efficiency.

4. Know the Workpiece Material

Understanding the properties of the materials you are working with is vital for successful injection molding. Different materials behave differently under heat and pressure, which can affect the molding process. For instance, when using polycarbonate or other high-performance plastics, ensure that the injection temperatures and cooling times are adjusted accordingly.

The YIZUMI DP Series is equipped with features that allow for precise temperature control and monitoring, which are essential when working with diverse materials. Familiarizing yourself with the specific requirements of each material will empower you to make informed decisions during the injection process. This knowledge is a critical asset for operators aiming to produce high-quality components consistently.

5. Mind the Coolant Lines

Effective cooling is a cornerstone of successful injection molding. Coolant lines play a crucial role in regulating mold temperatures, preventing overheating, and ensuring that the cycle times remain efficient. When operating the YIZUMI DP Series, inspect the coolant lines regularly to ensure they are free from blockages and leaks.

Proper coolant management not only enhances production efficiency but also prolongs the life of both the molds and the machine. Maintaining optimal temperatures prevents warping and other defects that can arise from improper cooling. At YIZUMI, we design our machines with advanced cooling systems to support your production goals, but it is essential that operators actively manage these systems for best results. The finish of a molded part can greatly affect its functionality and aesthetic appeal. Operators should develop an understanding of how different settings affect surface finishes. For example, the speed of injection, cooling time, and mold temperature can all influence the final appearance of the part.

With the YIZUMI DP Series, you have access to advanced technology that allows for precise control over these variables. Experimenting with different settings can help you achieve the desired finish while also reducing scrap rates. By fine-tuning these aspects, you will not only meet quality standards but also enhance the overall productivity of your operations.

Conclusion

Operating a two-platen injection molding machine, particularly the YIZUMI DP Series, requires a combination of technical knowledge, attention to detail, and a deep understanding of materials and processes. By following these five essential tips—understanding components, precise measurements, careful tool offsets, material knowledge, effective coolant management, and surface finish awareness—you can significantly improve your efficiency and output quality.

As a dedicated manufacturer of injection molding machines, we are deeply committed to achieving excellence in every aspect of our business. Our primary goal is to empower our customers by providing them with not only the most advanced machinery but also the essential knowledge and support required to thrive in their molding operations. We understand that the landscape of manufacturing is constantly evolving, and to remain competitive, businesses must adapt and optimize their production processes.

By leveraging our cutting-edge technologies and innovative solutions, you can enhance the efficiency and effectiveness of your operations. Our machines are designed with precision engineering and user-friendly features that enable you to maximize output while maintaining high-quality standards. Moreover, we offer comprehensive training and resources, ensuring that your team is well-equipped to utilize our equipment to its fullest potential.

In this dynamic industry, staying ahead of the competition is crucial. Our commitment to excellence means that we continuously invest in research and development to bring you the latest advancements. By partnering with us, you gain access to a wealth of expertise and state-of-the-art solutions that will help you streamline your processes, reduce costs, and improve product quality. Together, we can navigate the challenges of modern manufacturing and achieve lasting success in your business.

For those looking to enhance their expertise in injection molding, embracing these best practices will yield significant benefits in both productivity and quality. If you want to experience more about the charm of molding equipment, please visit YIZUMI's website!