Machine Introduction Video

Home

Products & Solutions

Polymer Process

Injection Molding Solutions

Product

Two-platen Injection Molding Machine

DP Series Two-platen Injection Molding Machine

Specialized solutions for diverse applications. This Two-platen Injection Molding Machine features injection compression molding (ICM), FoamPro microcellular foam technology, precision mold-open/close, carbon fiber lightweighting, long glass fiber (LGF) injection molding, and multi-material micro injection molding. Available with clamping forces from 5,50 to 4,000 tons.

Precise

Efficient

Energy-saving

Machine Introduction Video

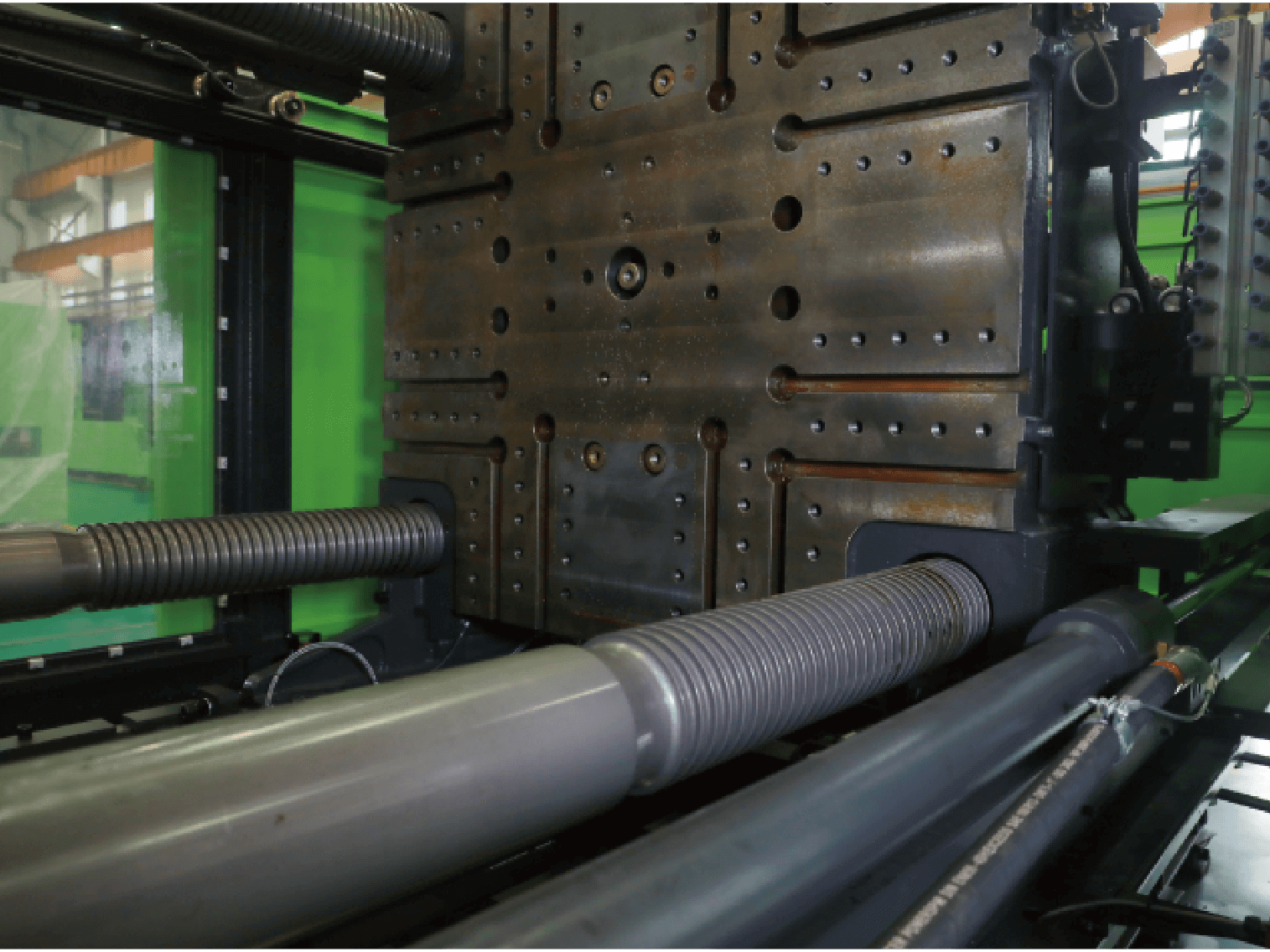

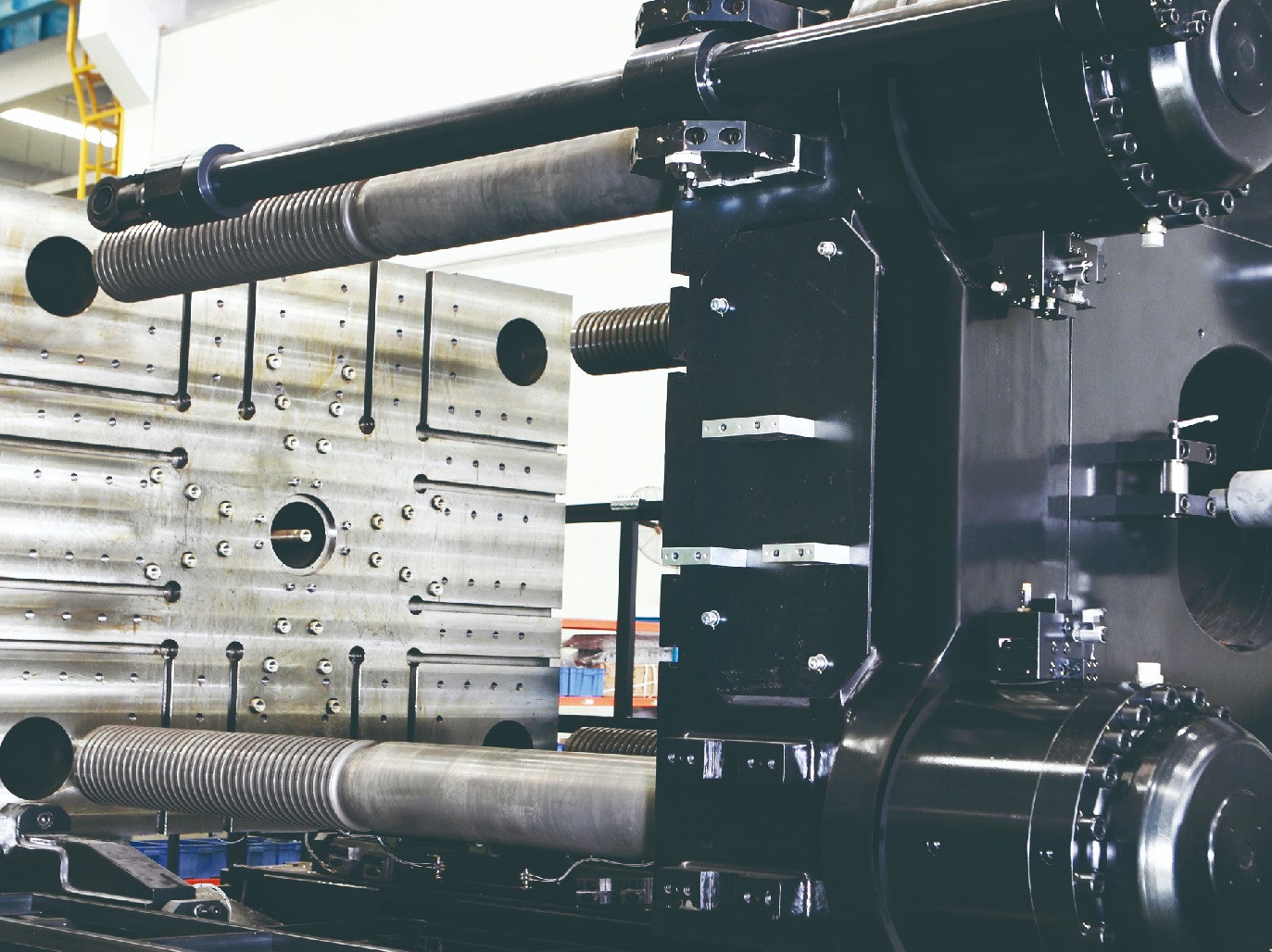

Clamping Unit

Synchronous locking nut mechanism

The fast, reliable and durable synchronous locking nut mechanism is driven by patented impact-cushioning cylinders and performs movements accurately.

Highly-rigid extended platen supports

The movable platen is supported by exceptionally long, rigid

sliding shoes with the function of tilt adjustment and L-shape guide design, providing steady support and precise guidance for large molds.

sliding shoes with the function of tilt adjustment and L-shape guide design, providing steady support and precise guidance for large molds.

Automatic tie bar retraction

The automatic tie bar retraction function is optional and

designed with stability and reliability. It can remove the

restriction of factory ceiling height

designed with stability and reliability. It can remove the

restriction of factory ceiling height

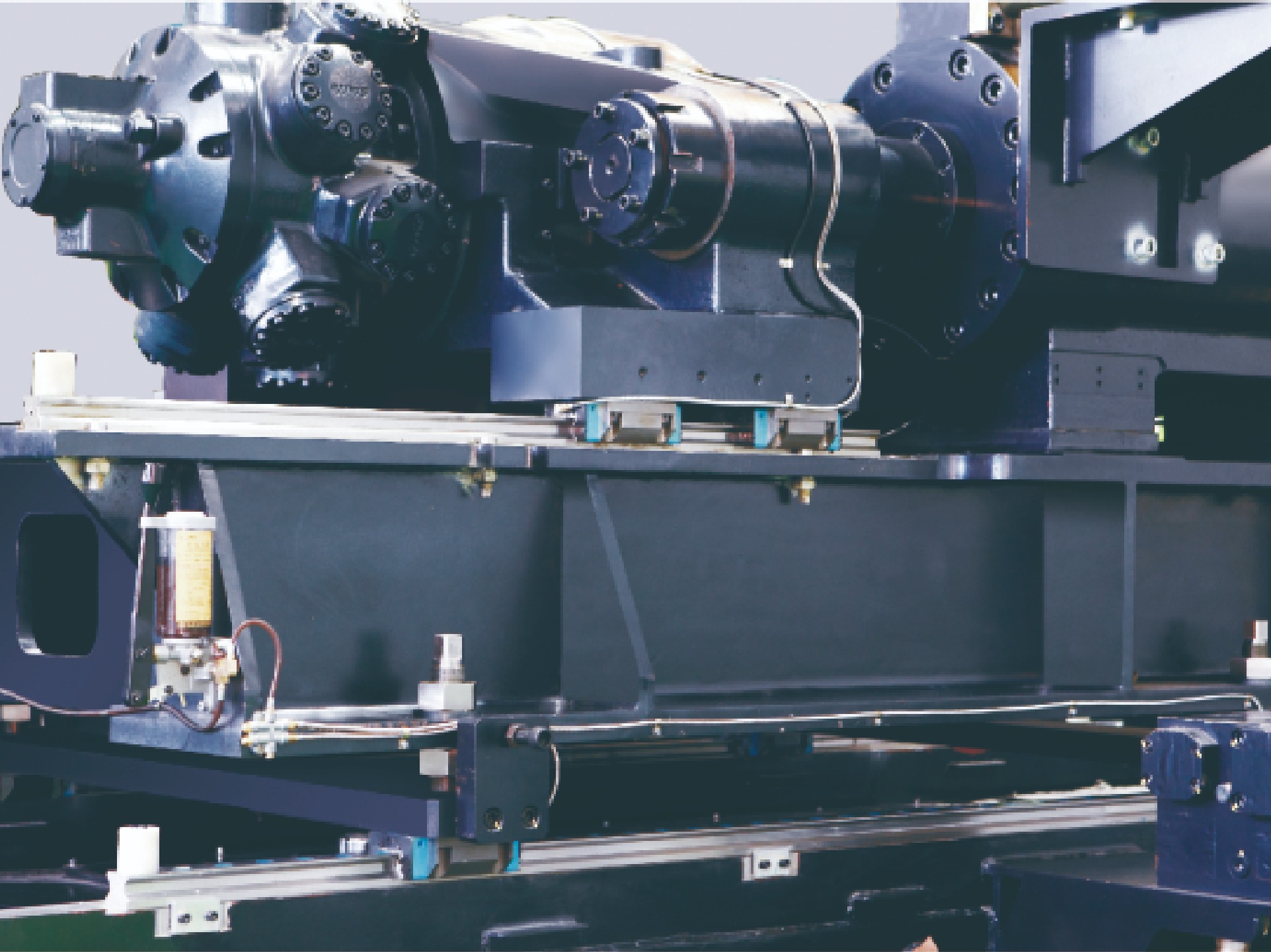

Injection Unit

Carriage supports and linear guide rails

High-rigidity carriage supports and double-deck guide rails are designed with low resistance and ensure high injection precision.

Ultrasonic digital displacement sensor

Injection and injection carriages are equipped with ultrasonic displacement sensors which are resistant to interference and durable, with measurement accuracy up to 0.001%/F.S

Injection carriage cylinder

Two injection carriages are parallel located. The universal coupling used for connection ensures stable nozzle contact and no plastic leak.

Hydraulic System

- The excellent performance of the DP series benefits from the high-performance Ecoservo drive technology and the piston variable pump, which has strong power, fast response, little internal leak, and significant energy savings.

- The drive system and injection unit will be matched in the form of modules so as to customize the power for the machine and minimize energy loss.

- Mold opening during plasticizing, ejection, or core pulling is a standard feature that reduces cycle time.

- The drive system and injection unit will be matched in the form of modules so as to customize the power for the machine and minimize energy loss.

- Mold opening during plasticizing, ejection, or core pulling is a standard feature that reduces cycle time.

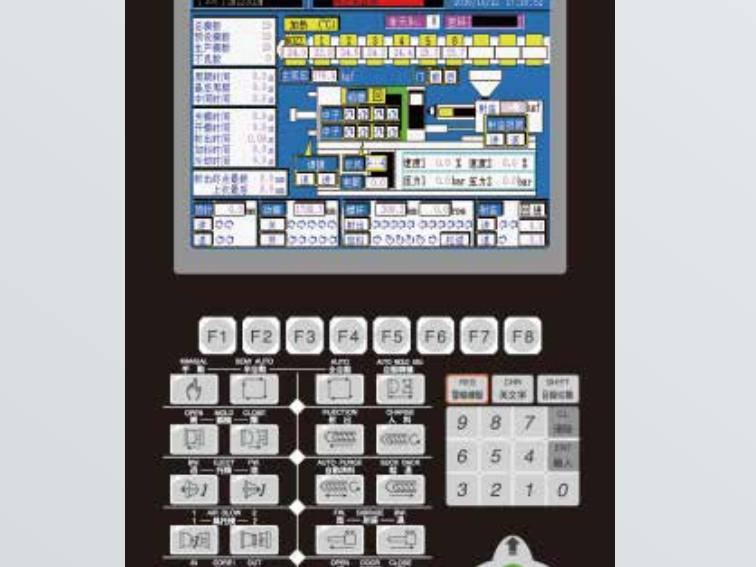

European KEBA Controller

- DP series employs Austria's KEBA control system with user-friendly interface and higher processing speed. It is also powerful and capable of providing multiple control software solutions for special processes.

- 15” TFT color touch screen, visualized graphic parameter setting, actual parameter values recorded and displayed with curves, more accurate online process analysis.

- Free programming is available to meet the needs of special molds and processes. The sequence of machine movements also can be freely edited.

- Extensible I/O modules can integrate with more functions, including temperature control and sequence valve as needed.

- Communication ports for printer, auxiliary equipment and automation.

- 15” TFT color touch screen, visualized graphic parameter setting, actual parameter values recorded and displayed with curves, more accurate online process analysis.

- Free programming is available to meet the needs of special molds and processes. The sequence of machine movements also can be freely edited.

- Extensible I/O modules can integrate with more functions, including temperature control and sequence valve as needed.

- Communication ports for printer, auxiliary equipment and automation.

Product Video

Industry Application

Relevant Recommendation

Relevant Products

Relevant Technologies

Service Process

01

Process/Mold Analyse and Design

- Raw materials selection

- Product design

- Mold flow analysis

- Mold design suggestion

02

Equipment Selection Suggestions

- Product performance

- Product quality

- Ease of use

- Safety requirements

03

Whole Plant Planning Advice

- Planning of production line

- Arrangements for people, machines, and materials according to process flow

- Peripheral automation

- Smart connection

04

Delivery Solutions

- Professional installation and debugging

- On-site operation training

- Molding process training

05

After Sales Solutions

- YFO services

- Preventive maintenance

- Device upgrade

Download

Contact Us

Please leave your message, and we will contact you soon!

I hereby give my consent for my personal data, collected and processed by YIZUMI in relation to my inquiry.

Contact Us

Please leave your message, and we will contact you soon!

I hereby give my consent for my personal data, collected and processed by YIZUMI in relation to my inquiry.