Home

Products & Solutions

Polymer Process

Injection Molding Solutions

Product

Multi-component Injection Molding Machine

CE-P Series High-end Electric Multi-component Injection Molding Machine

The CE-P Series electric multi-component injection molding machine is ideal for auto parts, medical, and 3C electronics, and offers advanced technology and efficiency. With refined control, quiet operation, and energy efficiency, it maintains YIZUMI's versatility and reliability. Clamping forces: 1,500-5,500 kN.

Low carbon

Flexibility

Clamping Unit

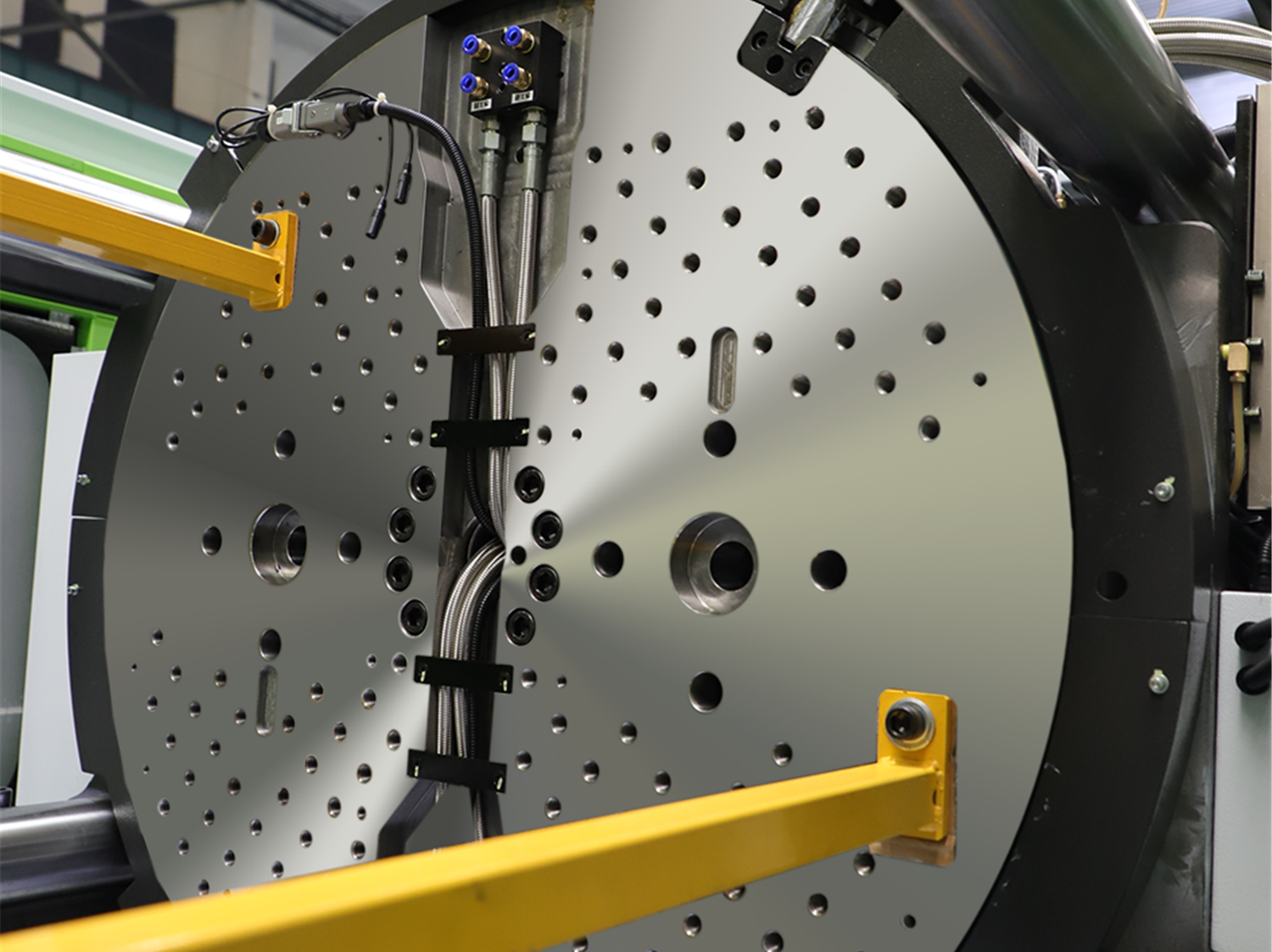

Reliable and stable with fast rotating speed, accurate turntable positioning

- Based on the European platen design concept, platens are designed with higher rigidity and more accurate force analysis. The BFC (balanced force clamping) technology can adjust the clamping force transmission direction so that the force is applied to the mold more evenly, and injection molding is more precise and stable;

- Third-generation intelligent control technology on the turntable, faster rotating speed, more accurate positioning, and more durable and reliable.

- Third-generation intelligent control technology on the turntable, faster rotating speed, more accurate positioning, and more durable and reliable.

Balanced force clamping technology

- The BFC technology delivers high platen rigidity, long mold life.

- Easily-adjustable processes and minimized possible flashes, and better ensure molding accuracy and stability.

- Easily-adjustable processes and minimized possible flashes, and better ensure molding accuracy and stability.

Third-generation intelligent digital closed-loop positioning control (DCPC) technology

With the digital closed-loop positioning technology, turntable positioning is faster, more stable, and accurate.

Injection Unit

High injection repeatability

- The use of the world’s leading position sensors with 2 million CPR resolution provides reliable support for ultra-high precision position and speed control.

- High-precision linear guide support significantly reduces the friction of the plasticizing unit, providing improved pressure stability of plasticizing and injection.

- Combined with special screws for different materials and precise temperature control, it further improves the stability of injection and allows the product weight repeatability to reach 1‰.

- High-precision linear guide support significantly reduces the friction of the plasticizing unit, providing improved pressure stability of plasticizing and injection.

- Combined with special screws for different materials and precise temperature control, it further improves the stability of injection and allows the product weight repeatability to reach 1‰.

Advanced LGS (Linear Guide Support) technology

- Integrated design enhances the overall rigidity of the injection unit.

- No unnecessary friction. Fast forward and backward.

- No unnecessary friction. Fast forward and backward.

Low-carbon temperature control technology

Scientific low-carbon insulation technology, combined with precise temperature control and shear heating control of materials, offers remarkable energy savings.

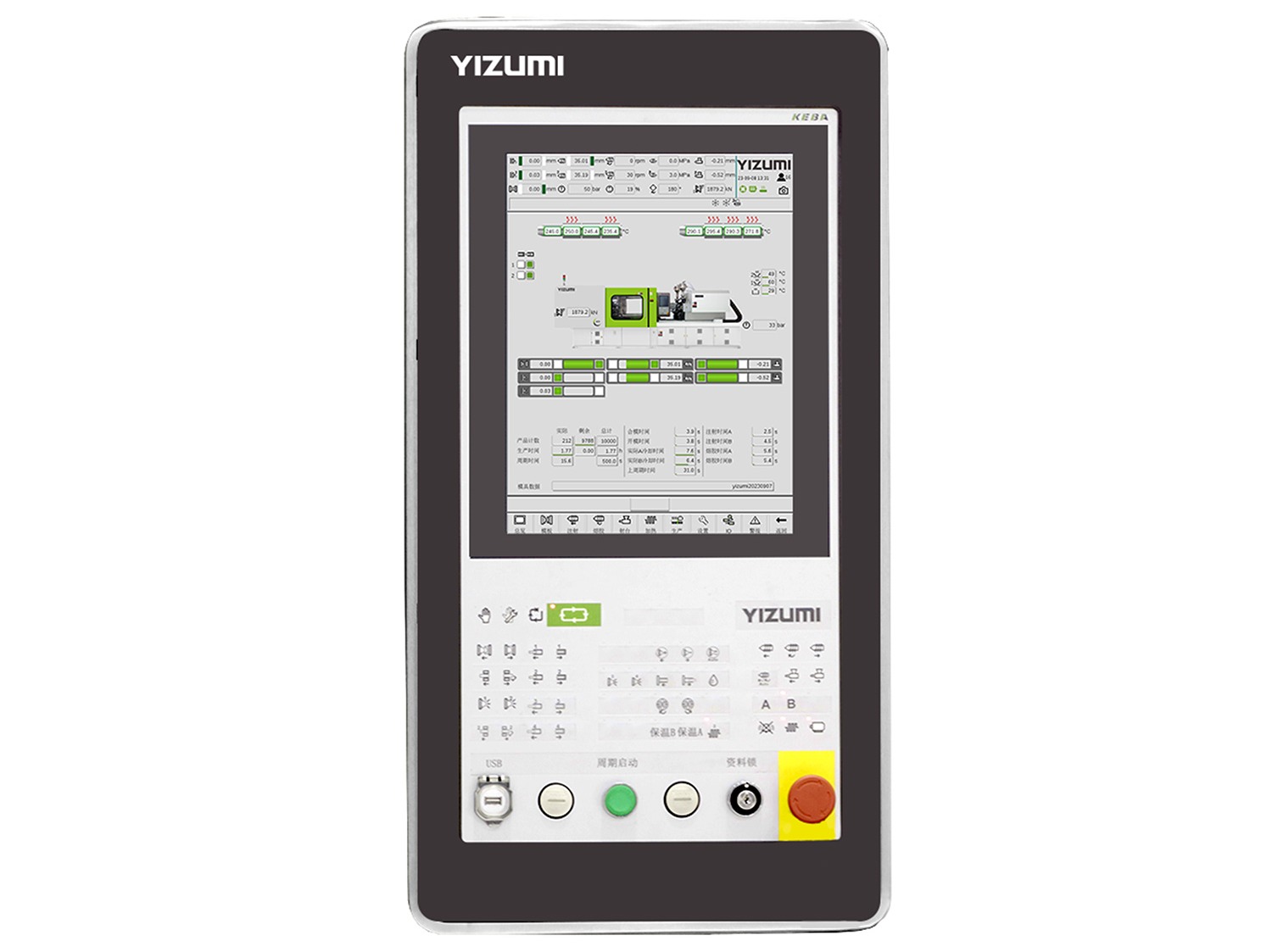

Intelligent, integrated, user-friendly HMI control system

Intelligent clamping management system

- Optional intelligent clamping force function allows real-time display and optimization of the machine's actual clamping force, helping save energy, improve product stability, and protect molds.

- Automatic optimization of process parameters is available.

- Automatic optimization of process parameters is available.

Flexible, interconnected, integrated

Through OPC UA, RS485, or other international standard interfaces to realize seamless connection with robots, mold temperature controllers, MES, and other auxiliary machines or management systems, providing an open, compatible, integrated system for IoE.

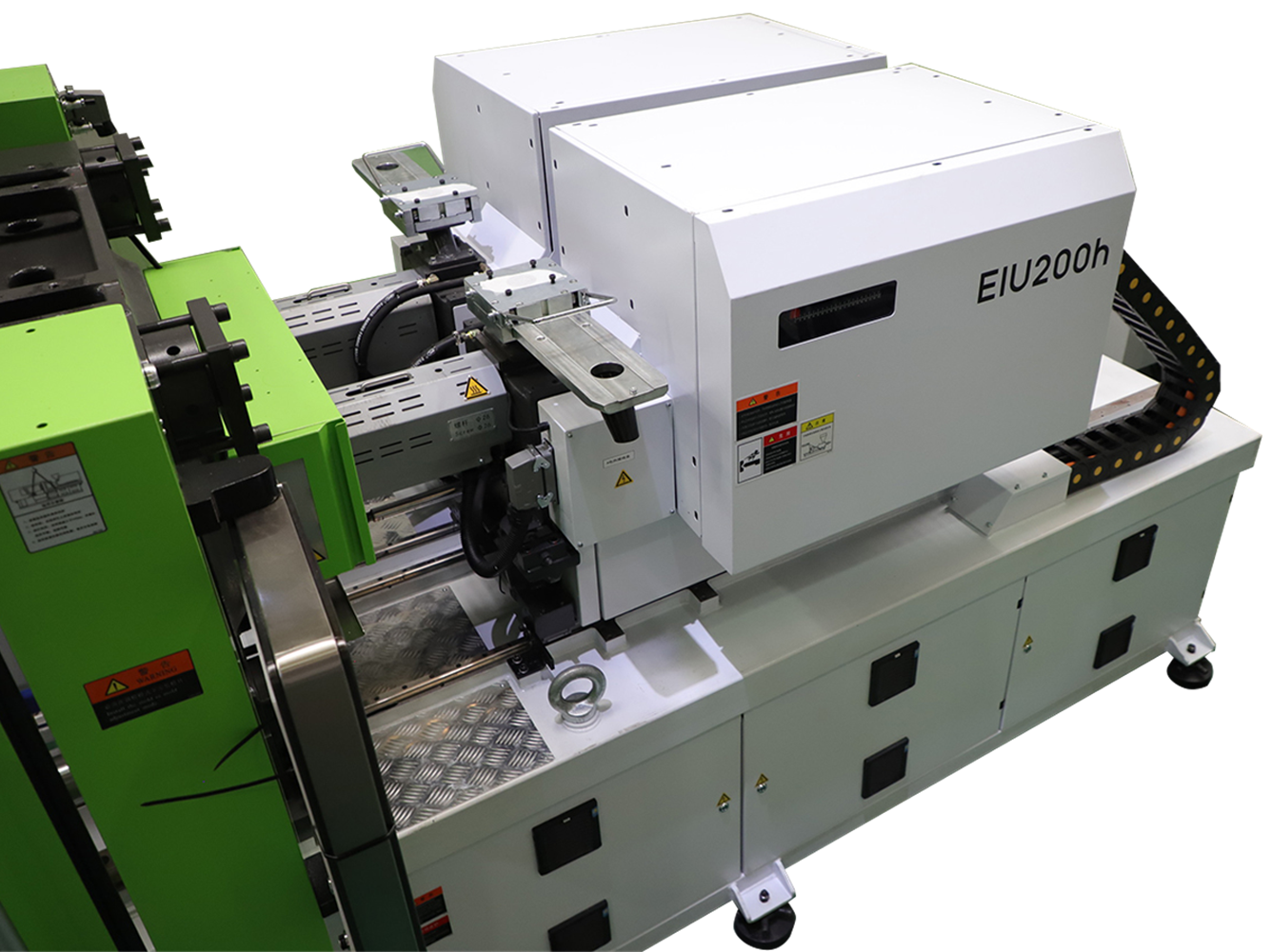

L/V Independent Injection Unit

Independent V injection unit

- Independent V-type injection unit adopts an independent modular design to meet the combination needs of injection molding machines of different tonnages.

- With YIZUMI's optimization design, the removal of the injection unit provides more mold height for convenient installation and disassembly.

- With YIZUMI's optimization design, the removal of the injection unit provides more mold height for convenient installation and disassembly.

Independent L injection unit

- Independent L-type injection unit adopts an independent modular design to meet the combination needs of injection molding machines of different tonnages and different brands.

- The flexible injection unit is convenient for use, providing a series of functions including core pulling, sequential valve, hot runner, and synchronous action.

- The flexible injection unit is convenient for use, providing a series of functions including core pulling, sequential valve, hot runner, and synchronous action.

Product Video

Industry Application

Relevant Recommendation

Relevant Products

Relevant Technologies

Relevant Automation

Service Process

01

Process/Mold Analyse and Design

- Raw materials selection

- Product design

- Mold flow analysis

- Mold design suggestion

02

Equipment Selection Suggestions

- Product performance

- Product quality

- Ease of use

- Safety requirements

03

Whole Plant Planning Advice

- Planning of production line

- Arrangements for people, machines, and materials according to process flow

- Peripheral automation

- Smart connection

04

Delivery Solutions

- Professional installation and debugging

- On-site operation training

- Molding process training

05

After Sales Solutions

- YFO services

- Preventive maintenance

- Device upgrade

Download

Contact Us

Please leave your message, and we will contact you soon!

I hereby give my consent for my personal data, collected and processed by YIZUMI in relation to my inquiry.

Contact Us

Please leave your message, and we will contact you soon!

I hereby give my consent for my personal data, collected and processed by YIZUMI in relation to my inquiry.