Home

Products & Solutions

Polymer Process

Injection Molding Solutions

Product

High-speed Injection Molding Machine

P-E Series High-speed Injection Molding Machine

The P-E Series High-speed injection molding machines feature servo motors and efficient transmission, offering 30-50% energy savings compared to standard models (depending on conditions). With a built-in hydraulic pump station, they provide flexibility for various mold processes. The fast dry cycle time of 2-2.6 seconds ensures enhanced production efficiency. Clamping forces range from 200 to 350 tons.

More accurate control

More stable operation

More energy-saving control system

More highly-efficient production

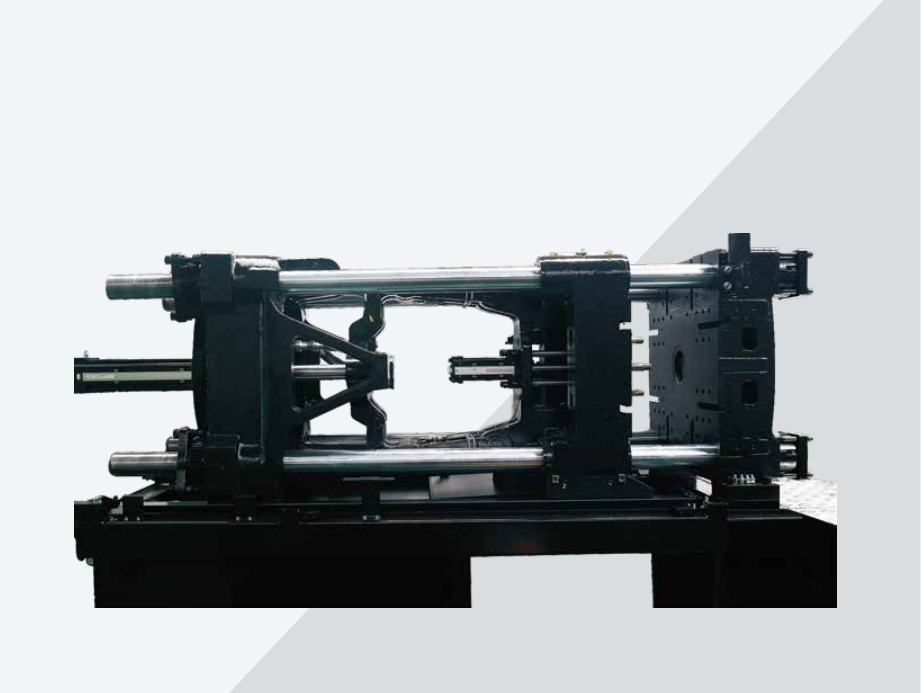

Clamping Unit

High stability of the tie-bar free (TBF) technology

- The clamping unit adopts the TBF (Tie Bar Free) technology for easy operation and maintenance.

- Keep the mold area clean to prevent product contamination.

- Keep the mold area clean to prevent product contamination.

Unique large beveled crosshead toggles design

- A large beveled structure can better transfer force from the tail toggle hole to the center of the platen to minimize the platen deformation.

- The overall optimization of toggle strength and rigidity.

- The overall optimization of toggle strength and rigidity.

Unique “SMART” mold protection feature

- Can detect very small obstacles and resistance.

- Reduce the extent of mold damage when there are foreign objects in the mold cavity or faulty operation occurs.

- Reduce the extent of mold damage when there are foreign objects in the mold cavity or faulty operation occurs.

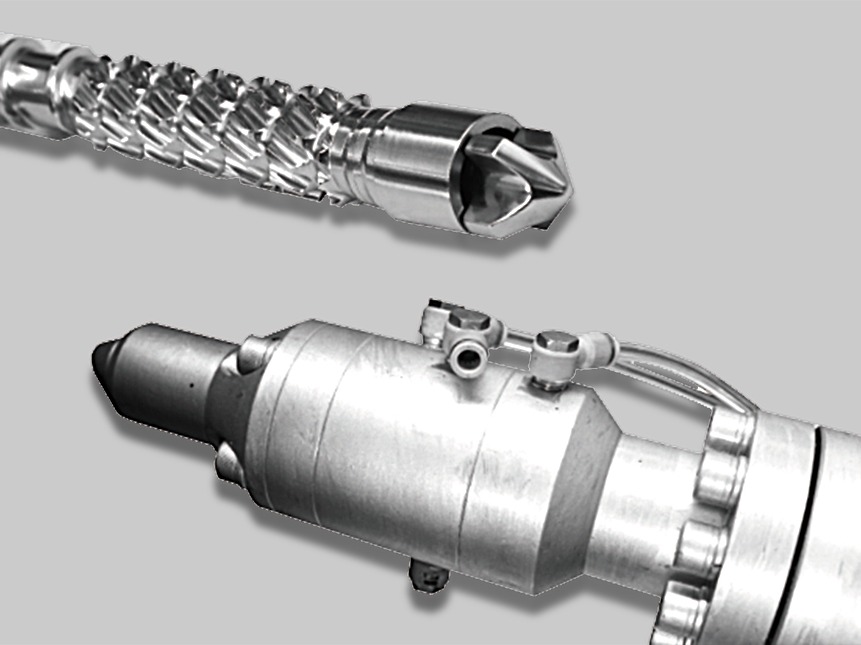

Injection Unit

Appropriate screw and barrel components

Professional screw and barrel components will be selected according to the characteristics of different raw materials and production processes to ensure the plasticizing quality.

Horizontal double-carriage design

- Effectively eliminate rotary torque to ensure a reliable and stable injection.

- No unnecessary friction. Fast forward and backward.

- No unnecessary friction. Fast forward and backward.

Closed-loop injection pressure control technology

- Provide more accurate control for more stable, reliable, and precise molding.

- The stability precision of injection pressure and holding pressure is at ±0.02Mpa.

- The stability precision of injection pressure and holding pressure is at ±0.02Mpa.

European KEBA2000 controller

- The powerful system is easy to operate and ideal for high-performance solutions for electric injection molding machines;

- 15-inch HD color touchscreen display with clear and neat screen layout;

- Standard features: Process Quality Control (PDP) and Statistical Process Control (SPC);

- Oscilloscope with chart display function to record the curve of process data change;

- Centralized (networked) real-time remote operation and control;

- Advanced HW and SW systems to support Industry 4.0;

- 1ms scan cycle;

- 16 levels of user access management to ensure data security.

- 15-inch HD color touchscreen display with clear and neat screen layout;

- Standard features: Process Quality Control (PDP) and Statistical Process Control (SPC);

- Oscilloscope with chart display function to record the curve of process data change;

- Centralized (networked) real-time remote operation and control;

- Advanced HW and SW systems to support Industry 4.0;

- 1ms scan cycle;

- 16 levels of user access management to ensure data security.

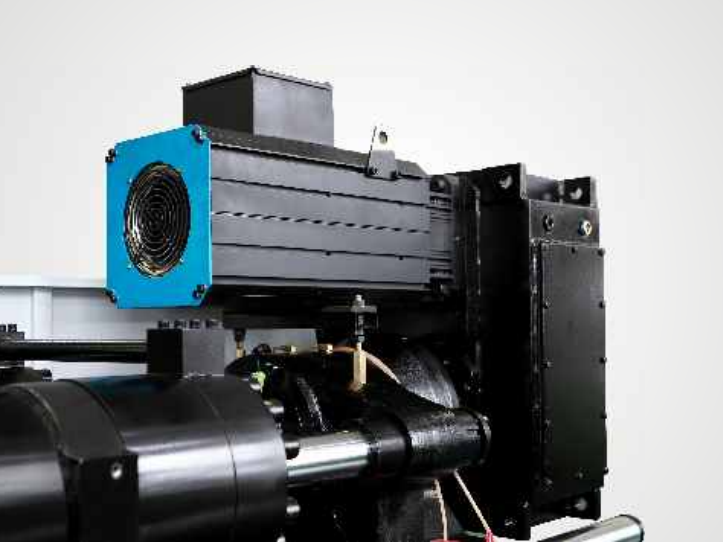

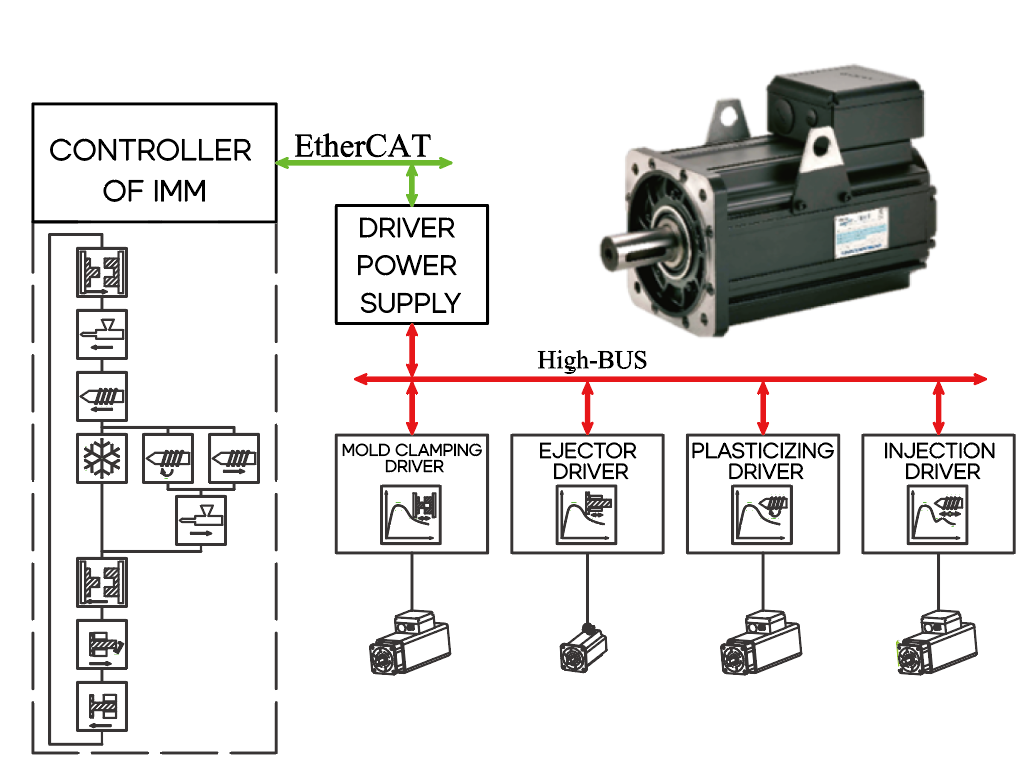

Unique servo direct control (SDC) technology

- Process algorithm independently developed by YIZUMI for the servo drive;

- Servo motor controls injection, plasticizing, and clamping independently, allowing faster feedback, more responsive control, and improved control accuracy;

- More precise control of speed, position, and pressure to meet the requirements of precision equipment.

- Servo motor controls injection, plasticizing, and clamping independently, allowing faster feedback, more responsive control, and improved control accuracy;

- More precise control of speed, position, and pressure to meet the requirements of precision equipment.

Product Video

Industry Application

Relevant Recommendation

Relevant Products

Relevant Technologies

Relevant Processes

Service Process

01

Process/Mold Analyse and Design

- Raw materials selection

- Product design

- Mold flow analysis

- Mold design suggestion

02

Equipment Selection Suggestions

- Product performance

- Product quality

- Ease of use

- Safety requirements

03

Whole Plant Planning Advice

- Planning of production line

- Arrangements for people, machines, and materials according to process flow

- Peripheral automation

- Smart connection

04

Delivery Solutions

- Professional installation and debugging

- On-site operation training

- Molding process training

05

After Sales Solutions

- YFO services

- Preventive maintenance

- Device upgrade

Download

Contact Us

Please leave your message, and we will contact you soon!

I hereby give my consent for my personal data, collected and processed by YIZUMI in relation to my inquiry.

Contact Us

Please leave your message, and we will contact you soon!

I hereby give my consent for my personal data, collected and processed by YIZUMI in relation to my inquiry.