Home

Products & Solutions

Polymer Process

Injection Molding Solutions

Product

Special-usage Injection Molding Machine

LSR Series Liquid Silicone Injection Molding Machine

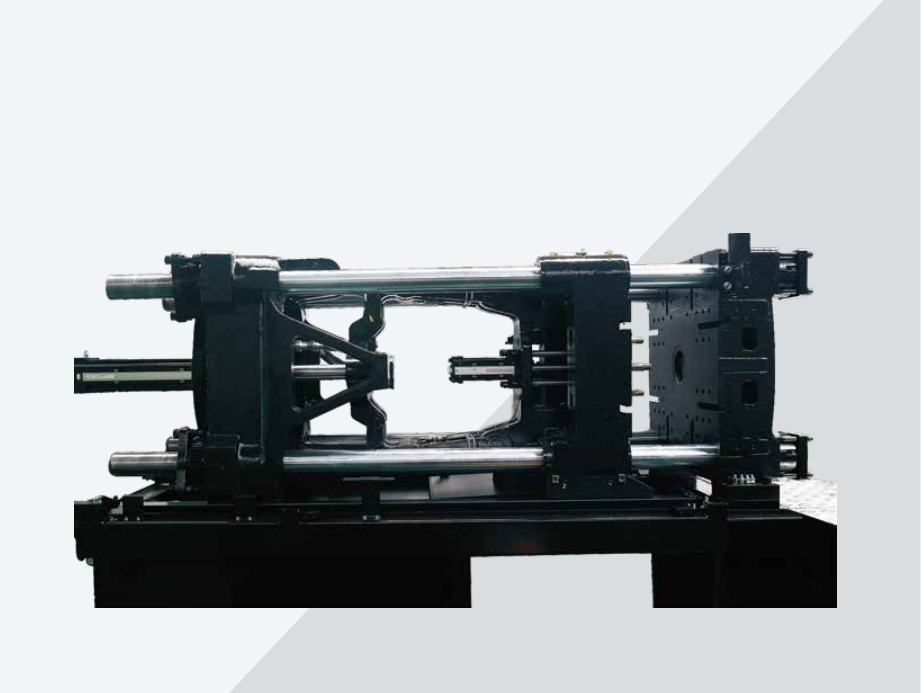

LSR Series represents a shift from traditional thermoplastics to advanced thermoset plastics, encompassing both hard (bakelite/BMC) and soft (liquid silicone) processes. This liquid silicone injection molding machine integrates a specialized liquid silicone injection unit with the SKII platform, offering high precision and stability. This special-usage injection molding machine is designed for efficient, precise material blending, vulcanization, and solidification, meeting the dynamic needs of modern markets with improved product yield.

More Efficient

More Professional

Customized Design

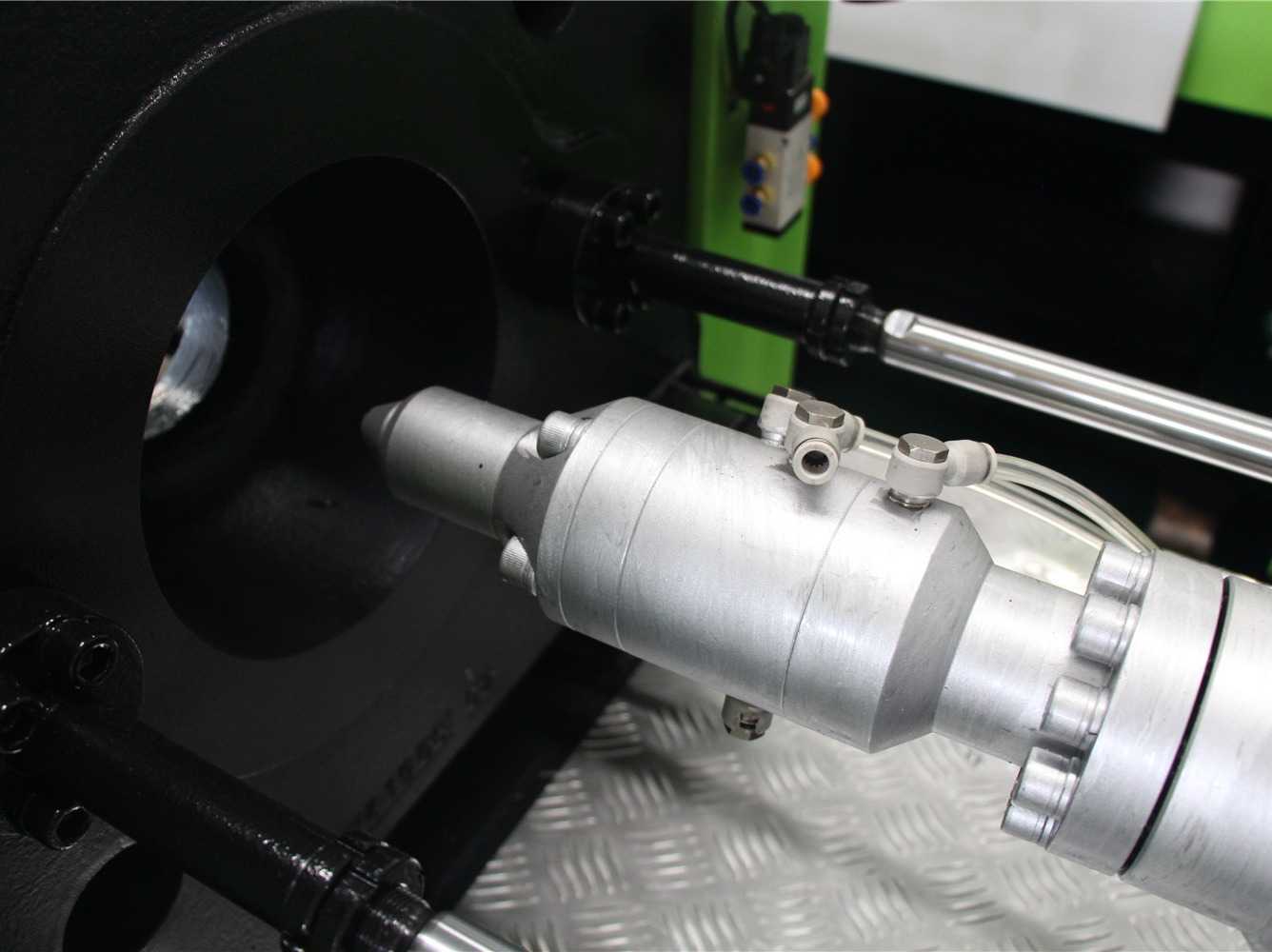

Standard pneumatic injection nozzle

Water-cooled pneumatic injection nozzle - prevents liquid silicone leakage, and prevents the mold temperature from being transmitted to nozzle and resulting in curing reaction of mixed LSR in the nozzle.

Mixing screw for silicone

- Mixed compounds at the front end of the screw to ensure the fully blending of components A and B while eliminating phenomena such as adhesion, yellowing, or blackening;

- Sensitive seal rings are used as an adaptation to the high liquidity of silicone resin to reduce leakage during injection start-up and injection.

- Sensitive seal rings are used as an adaptation to the high liquidity of silicone resin to reduce leakage during injection start-up and injection.

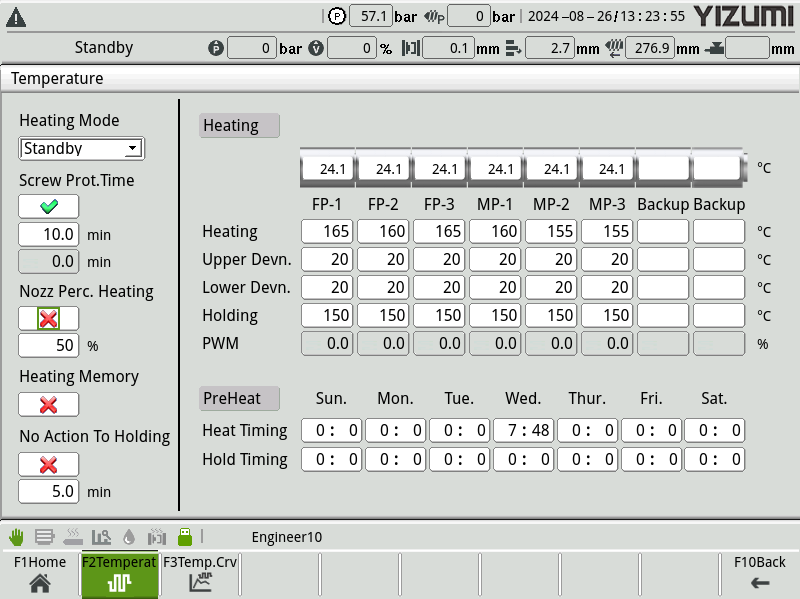

Temperature control for mold heating

- Visualized built-in mold temperature control to facilitate temperature adjustment.

- Separate connecting socket for each set of heating units for the convenience of customers.

- Separate connecting socket for each set of heating units for the convenience of customers.

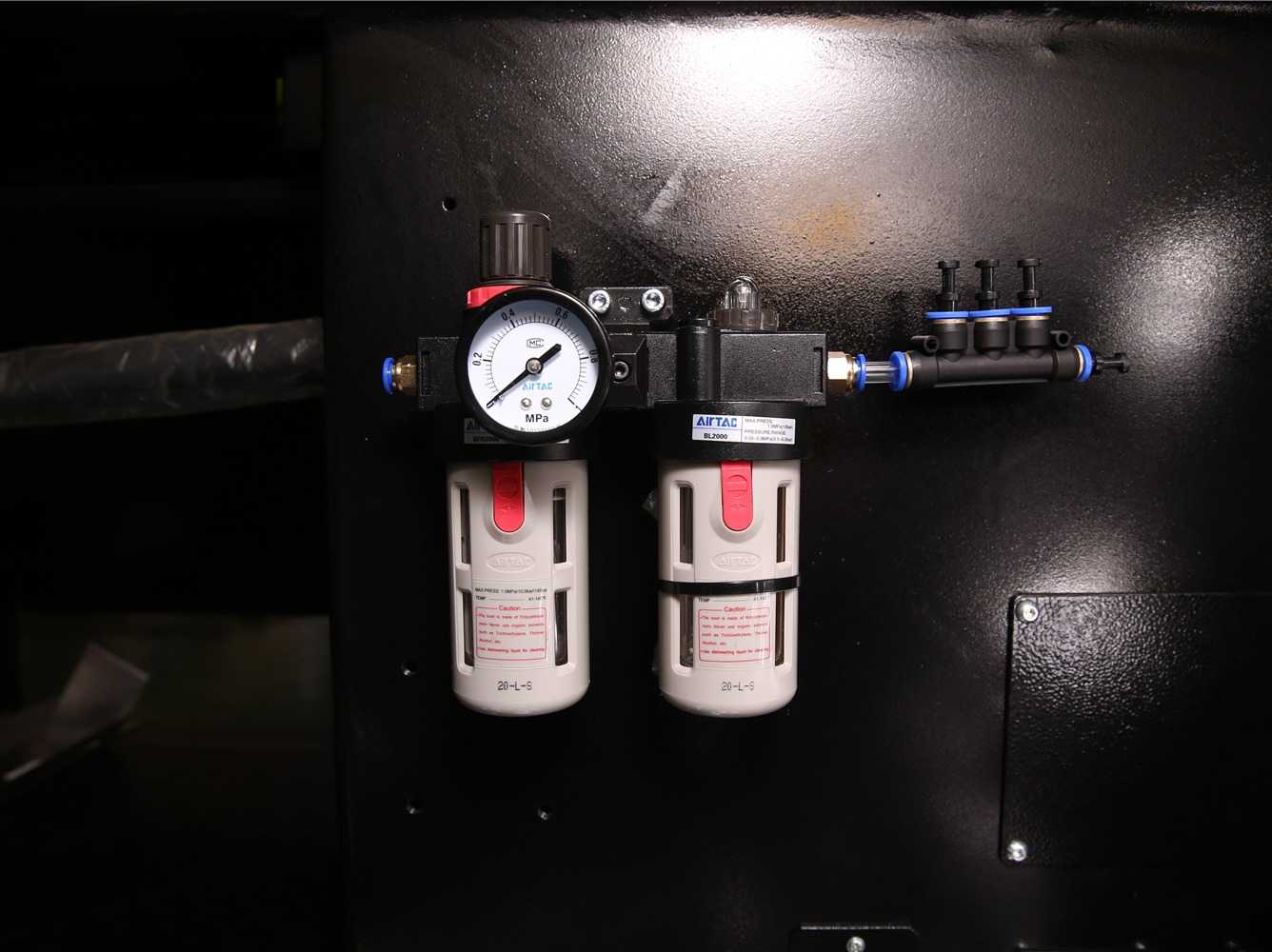

Standard pneumatic 2-piece filter and air gun fittings

User friendly design for easy connection to the air gun and silicone feeder on site

Auxiliary Equipment - YIZUMI liquid silicone feeder

- Fully pneumatic secondary metering system, energy efficient and pollution-free;

- Manual correction of A/B material component ratio. The ratio error is less than 3%;

- Maintenance-free design - silicone leakage free, less waste;

- Uniform color mixing with no flow marks, high repetition accuracy.

- Manual correction of A/B material component ratio. The ratio error is less than 3%;

- Maintenance-free design - silicone leakage free, less waste;

- Uniform color mixing with no flow marks, high repetition accuracy.

Product Video

Industry Application

Relevant Recommendation

Relevant Products

Relevant Technologies

Service Process

01

Process/Mold Analyse and Design

- Raw materials selection

- Product design

- Mold flow analysis

- Mold design suggestion

02

Equipment Selection Suggestions

- Product performance

- Product quality

- Ease of use

- Safety requirements

03

Whole Plant Planning Advice

- Planning of production line

- Arrangements for people, machines, and materials according to process flow

- Peripheral automation

- Smart connection

04

Delivery Solutions

- Professional installation and debugging

- On-site operation training

- Molding process training

05

After Sales Solutions

- YFO services

- Preventive maintenance

- Device upgrade

Download

Contact Us

Please leave your message, and we will contact you soon!

I hereby give my consent for my personal data, collected and processed by YIZUMI in relation to my inquiry.

Contact Us

Please leave your message, and we will contact you soon!

I hereby give my consent for my personal data, collected and processed by YIZUMI in relation to my inquiry.