Home

Products & Solutions

Polymer Process

Injection Molding Solutions

Product

Vertical Injection Molding Machine

VM Series Vertical Plastic Injection Molding Machine

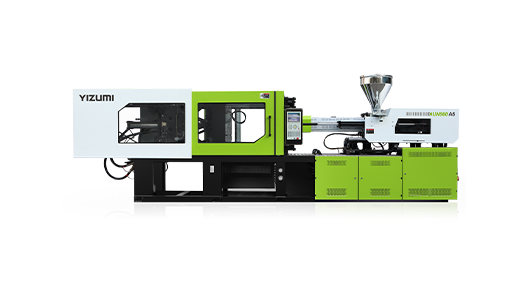

Vertical Plastic Injection Molding Machine VM Series provides precise control and stability with vertical injection. Reliable operation with direct clamping and high rigidity. Ideal for molding plastic products with inserts. Clamping forces: 600-3000 kN, perfect for versatile molding.

High precision

High efficiency

Energy saving

Optimized plasticizing screw

- The plasticizing efficiency is increased by 10%-30% and the quality of plasticizing and color mixing is improved as well.

- Four sets of standard barrel assemblies are available so that the machine has wider applicability.

- Four sets of standard barrel assemblies are available so that the machine has wider applicability.

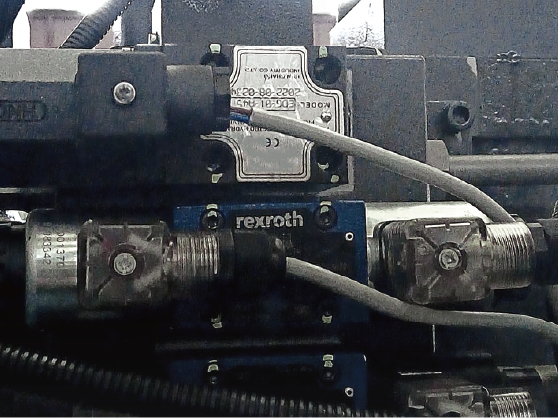

Proportional plasticizing back pressure control

Proportional back pressure facilitates accurate control of the industrial controller and enhances the stability of injection.

YIZUMi’s third-generation energy-saving servo technology

- The third-generation servo system has been improved and optimized in the internal structure of the motor, the standard of magnetic steel, the selection of the oil pump, and the development of drive software to achieve superior performance in stability, reliability, durability, energy conservation, efficiency, and low noise;

- Owing to the servo system, VM series machines use 30%-80% less energy than conventional hydraulic machines. The accuracy of closed-loop hydraulic oil temperature control, which is the new function, is ±0.5℃ with further increased stability.

- Owing to the servo system, VM series machines use 30%-80% less energy than conventional hydraulic machines. The accuracy of closed-loop hydraulic oil temperature control, which is the new function, is ±0.5℃ with further increased stability.

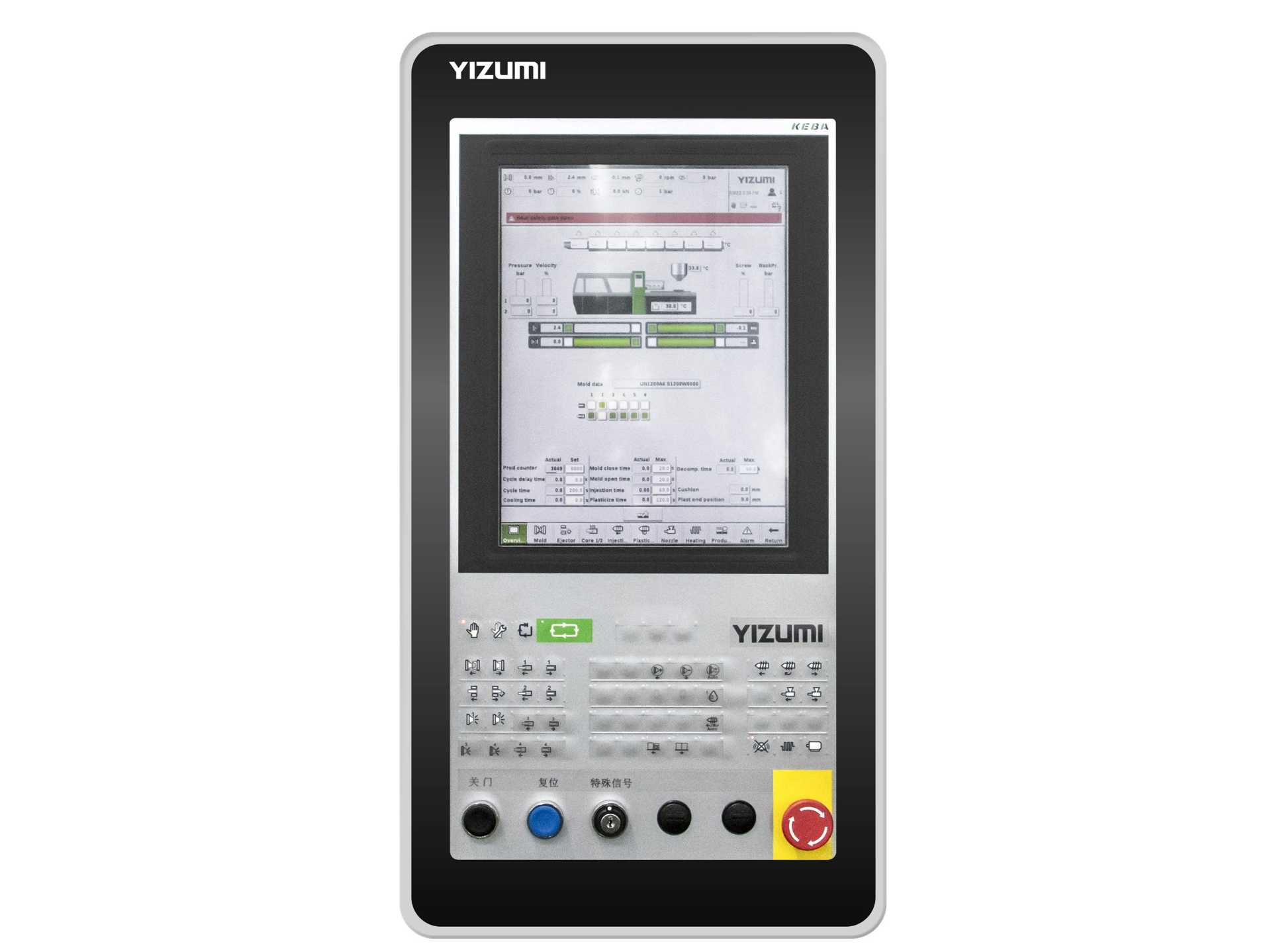

Upgraded KEBA system

- Expandable with multiple modules, including AO, AI, DO, DI, and TM, to meet more requirements;

- Real-time monitoring machine signals from sensors to coordinate corresponding movements for higher operating safety;

- Support common RS232/485 communication interface, CANOPEN, Ethernet port, temperature compensation sensor connector, and USB port.

- Real-time monitoring machine signals from sensors to coordinate corresponding movements for higher operating safety;

- Support common RS232/485 communication interface, CANOPEN, Ethernet port, temperature compensation sensor connector, and USB port.

Oil level detection

Automatic low oil level alarm prevents gas from being sucked in due to low oil level, avoiding consequent instability of hydraulic circuit.

Product Video

Industry Application

Relevant Recommendation

Relevant Products

Relevant Automation

Service Process

01

Process/Mold Analyse and Design

- Raw materials selection

- Product design

- Mold flow analysis

- Mold design suggestion

02

Equipment Selection Suggestions

- Product performance

- Product quality

- Ease of use

- Safety requirements

03

Whole Plant Planning Advice

- Planning of production line

- Arrangements for people, machines, and materials according to process flow

- Peripheral automation

- Smart connection

04

Delivery Solutions

- Professional installation and debugging

- On-site operation training

- Molding process training

05

After Sales Solutions

- YFO services

- Preventive maintenance

- Device upgrade

Download

Contact Us

Please leave your message, and we will contact you soon!

I hereby give my consent for my personal data, collected and processed by YIZUMI in relation to my inquiry.

Contact Us

Please leave your message, and we will contact you soon!

I hereby give my consent for my personal data, collected and processed by YIZUMI in relation to my inquiry.