Home

Products & Solutions

Polymer Process

Injection Molding Solutions

Product

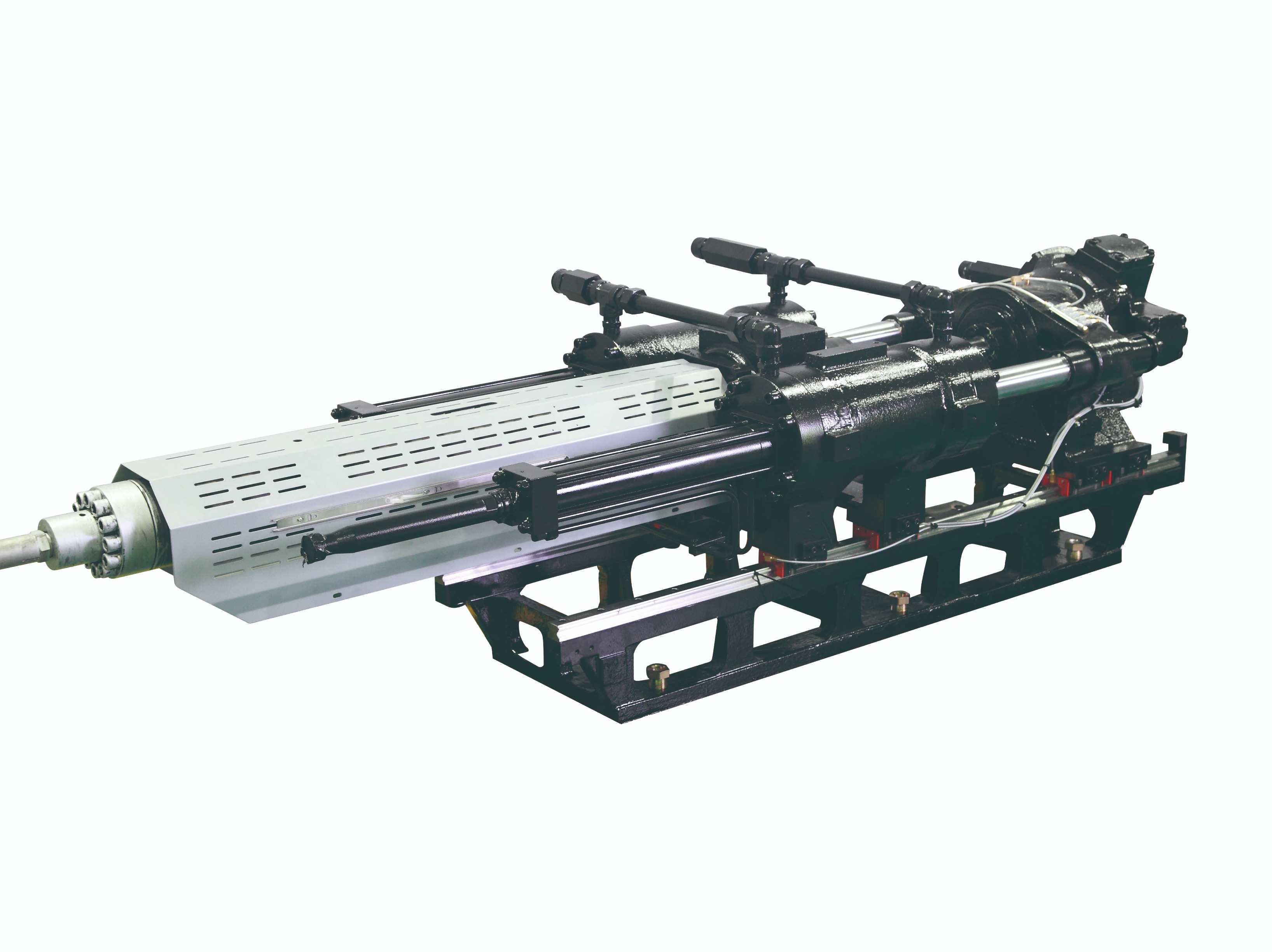

Toggle-clamping Hydraulic Injection Molding Machine

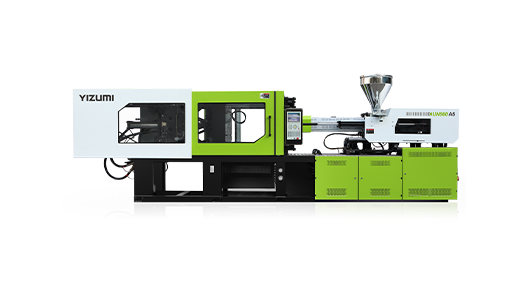

A5-EU Series High-end Servo Injection Molding Machine

Yizumi's new high-end servo injection molding machine, A5-EU series, offers precision, stability, and durability. Clamping forces range from 300 to 7,000 kN.

Precise and stable

Reliable and durable

High-efficiency and energy-saving

User-friendly

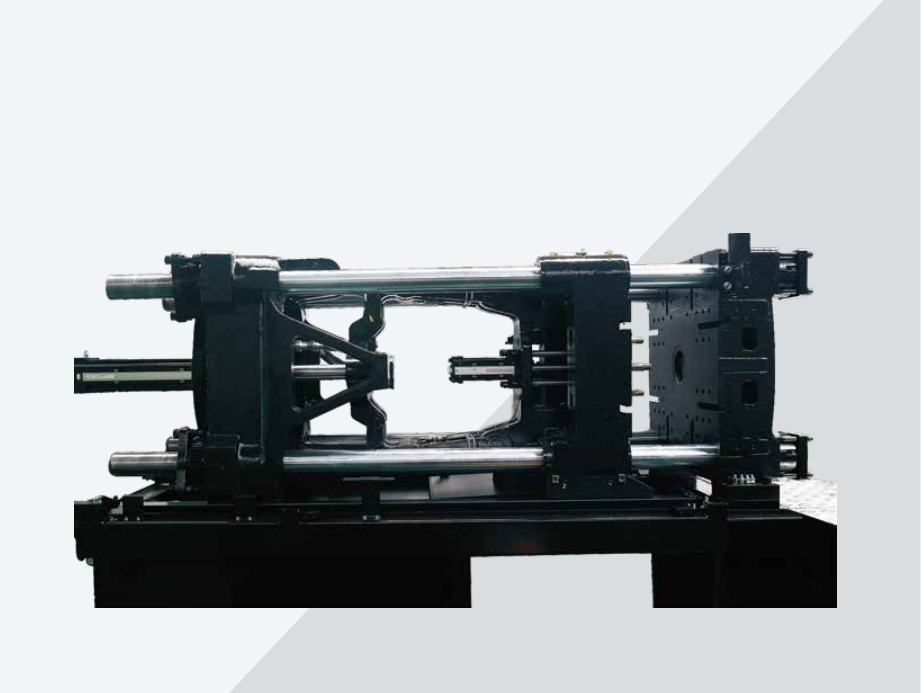

Clamping Unit

Stable and high-rigidity mechanical structure

- The T-slot platens are designed with a European-style structure and completely optimized with higher durability, less deformation, and better parallelism, so that the repeatability of clamping force is higher.

- Rigid materials and sophisticated processes are applied to the manufacturing of machine frame to ensure the machine is robust, stable, and reliable.

- Rigid materials and sophisticated processes are applied to the manufacturing of machine frame to ensure the machine is robust, stable, and reliable.

EUROMAP 2-based ejector hole pattern and mold location hole

- Layout of the ejector holes in the movable platen is adjusted according to EUROMAP 2.

- Mold location holes in the movable platen and fixed platen are designed according to EUROMAP 2.

- Mold location holes in the movable platen and fixed platen are designed according to EUROMAP 2.

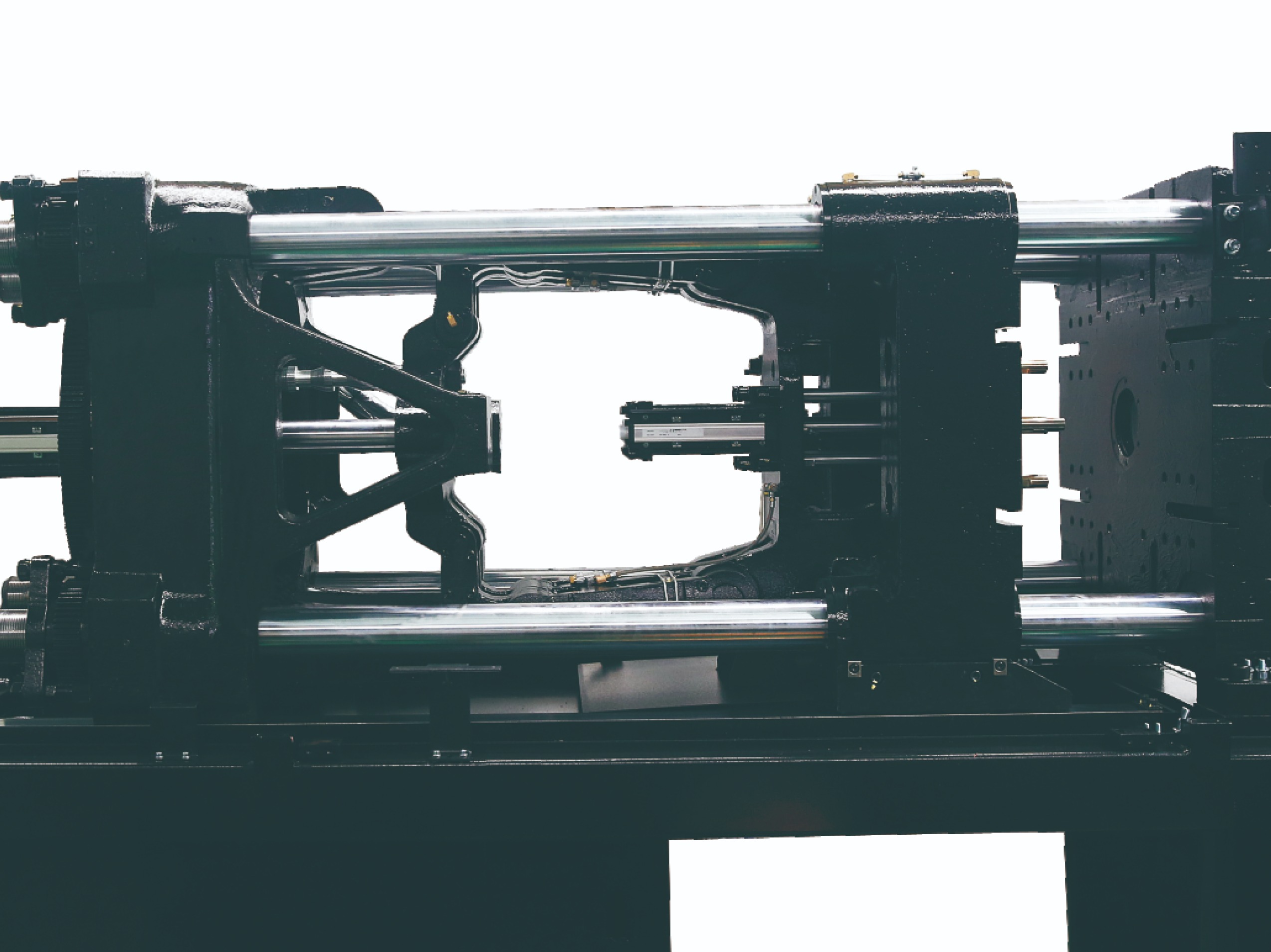

Highly rigid clamping unit

- The platens have little deformation and better parallelism. There is less stress variation on tie bars, and the repeatability of clamping force is higher.

- The machine is geared to high-speed and high-pressure special injection molding processes, effectively improving the precision of molded parts.

- The machine is geared to high-speed and high-pressure special injection molding processes, effectively improving the precision of molded parts.

Injection Unit

Integrated linear guide rail support

- The machine adopts integrated linear guide rail, horizontal double carriage design and double-cylinder injection to ensure injection is reliable and stable.

- Integrated linear guide rail support reduces the friction between injection unit and linear guide rail or tie bar and enhances production repeatability.

- Integrated linear guide rail support reduces the friction between injection unit and linear guide rail or tie bar and enhances production repeatability.

Proportional back pressure for plasticizing

Proportional back pressure facilitates accurate control by industrial computer and enhances the stability of injection.

Injection frame compatible with three types of injection unit

Pre-drilled mounting holes in the machine frame are fit for one size larger or smaller injection unit.

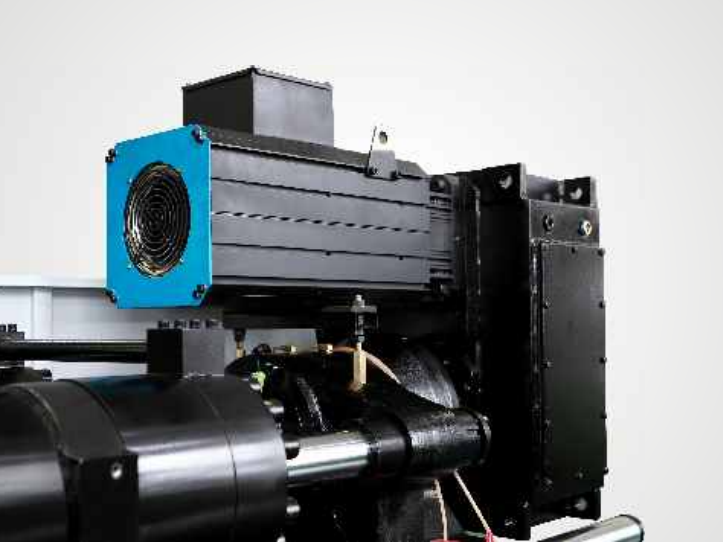

Yizumi third generation of energy saving servo technology

- The third-generation servo system has been improved and optimized in the internal structure of the motor, the standard of magnetic steel, the selection of oil pump, and the development of drive software to achieve superior performance in stability, reliability, durability, energy conservation, efficiency, and low noise.

- The servo system uses 30%-80% less energy than conventional hydraulic machines.

- The servo system uses 30%-80% less energy than conventional hydraulic machines.

High-precision control system

- A5-EU series is equipped with Austria's KEBA control system with a user-friendly interface and higher processing speed. It is also powerful and capable of providing multiple control software solutions for special processes.

- 10" TFT true color display with touch screen, film-covered buttons, and five open round interfaces.

- Multiple sets of mold data storage with USB ports that facilitate easy and simple operation.

- Program storage with an independent CF card, which is maintenance-friendly.

- Extensible I/O modules can integrate with more functions, including temperature control and sequence valve, as needed.

- Communication ports for printer, auxiliary equipment, and automation.

- 10" TFT true color display with touch screen, film-covered buttons, and five open round interfaces.

- Multiple sets of mold data storage with USB ports that facilitate easy and simple operation.

- Program storage with an independent CF card, which is maintenance-friendly.

- Extensible I/O modules can integrate with more functions, including temperature control and sequence valve, as needed.

- Communication ports for printer, auxiliary equipment, and automation.

Product Video

Industry Application

Relevant Recommendation

Relevant Products

Relevant Technologies

Relevant Automation

Service Process

01

Process/Mold Analyse and Design

- Raw materials selection

- Product design

- Mold flow analysis

- Mold design suggestion

02

Equipment Selection Suggestions

- Product performance

- Product quality

- Ease of use

- Safety requirements

03

Whole Plant Planning Advice

- Planning of production line

- Arrangements for people, machines, and materials according to process flow

- Peripheral automation

- Smart connection

04

Delivery Solutions

- Professional installation and debugging

- On-site operation training

- Molding process training

05

After Sales Solutions

- YFO services

- Preventive maintenance

- Device upgrade

Download

Contact Us

Please leave your message, and we will contact you soon!

I hereby give my consent for my personal data, collected and processed by YIZUMI in relation to my inquiry.

Contact Us

Please leave your message, and we will contact you soon!

I hereby give my consent for my personal data, collected and processed by YIZUMI in relation to my inquiry.