Home

Products & Solutions

Polymer Process

Injection Molding Solutions

Product

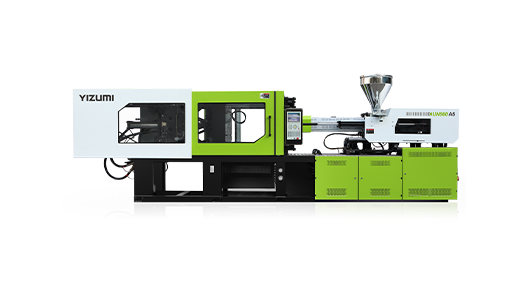

Toggle-clamping Hydraulic Injection Molding Machine

SKⅢ Series General Purpose Injection Molding Machine

General Purpose Plastic Injection Molding Machine SKⅢ series offers efficiency, energy savings, stability, and user experience. With SK/A5 platform interchangeability and continual optimization, it's the top choice for small to medium-sized machines. Clamping forces range from 900 to 10,000 kN.

More effective

More stable

More energy saving

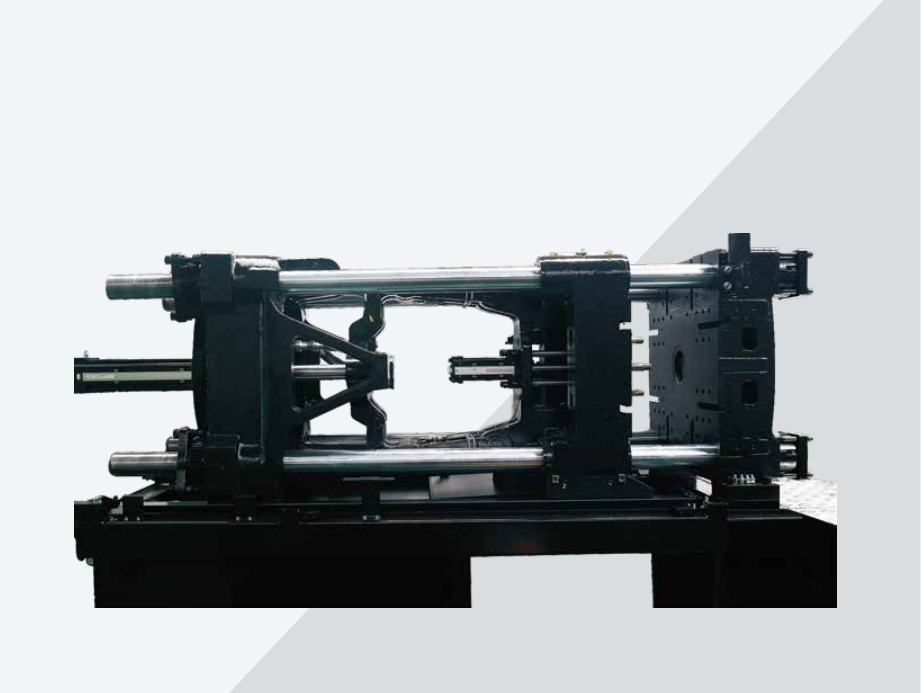

Clamping Unit

Strong central support to the movable platen structure

- Movable platen with strong central support minimizes platen deformation while achieving even distribution of clamping force;

- Use lower clamping force to reduce deformation of the mold cavity, improve product molding accuracy, and save energy.

- Use lower clamping force to reduce deformation of the mold cavity, improve product molding accuracy, and save energy.

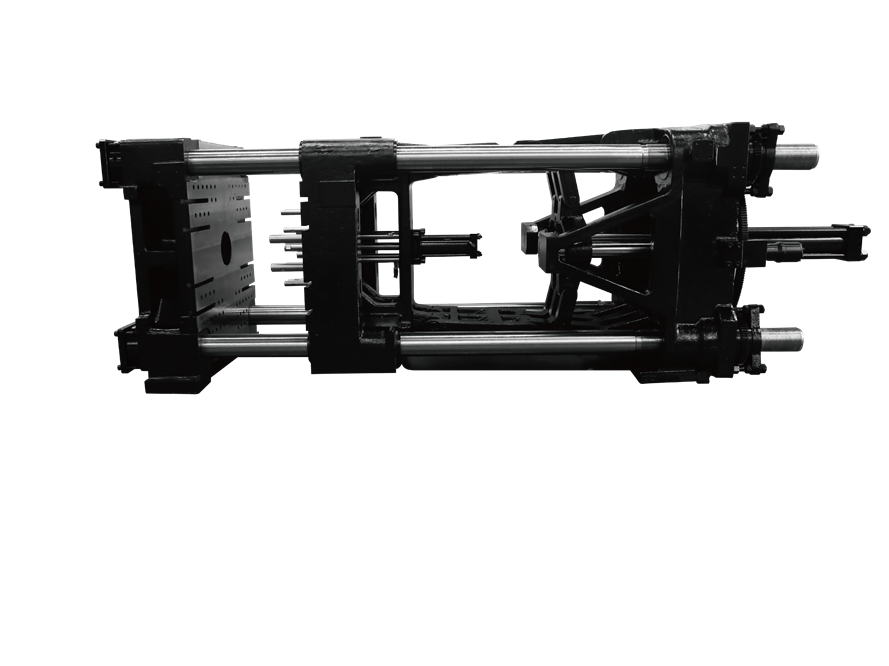

Highly rigid fixed platen and tail platen structure

Optimization of the fixed platen and tail platen structure to enhance rigidity and reduce mold deformation.

Tie bar and tie bar nut structure

The unique tie bar unloading groove design and the pitch diameter design for the tie bar and tie bar nut threads greatly reduce stress concentration, cause no damage to the tie bar and tie bar nut, and improve the reliability.

Injection Unit

Upgraded injection unit

- Injection linear guide structure: Reduce motion friction, increase injection accuracy, and enhance plasticizing efficiency;

- Linear carriage guide with dual-cylinder: Reduced motion friction resistance for easy operation and maintenance;

- Linear carriage guide with dual-cylinder: Reduced motion friction resistance for easy operation and maintenance;

Newly upgraded cooling system

Built-in cooling water circuits: Increase cooling area, improve cooling effect by more than 100%, reduce the risk of bridging raw materials, and make it easier to replace the barrel assembly.

Optimized injection unit

- Integral carriage support: Adopt integral carriage support to move forward the support points. Fixed the injection plate to improve the stability of the injection section;

- Easier injection unit change to shorten production lead time.

- Easier injection unit change to shorten production lead time.

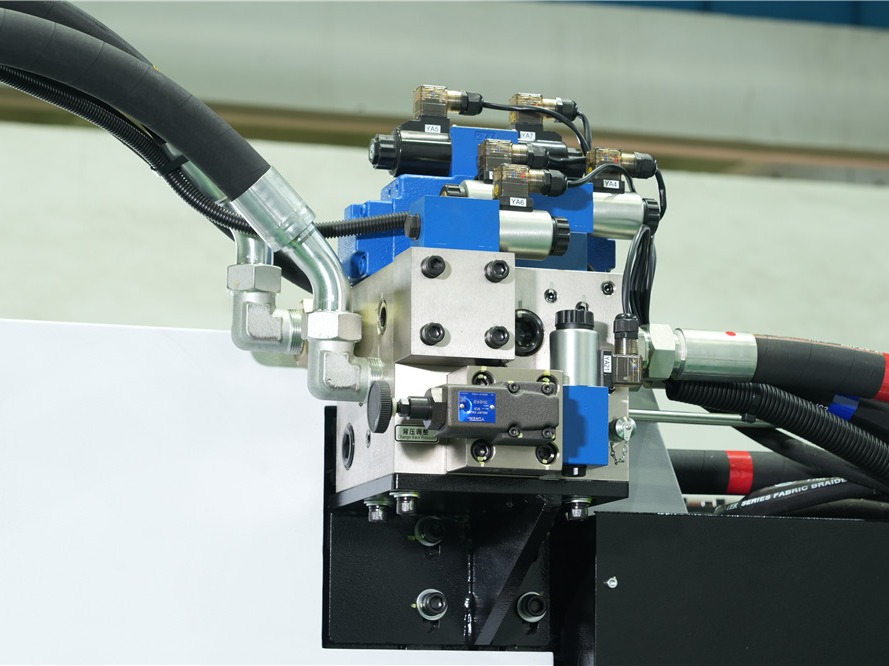

YIZUMI’s fourth-generation energy-saving servo technology

- The all-new servo drive system adopts one-piece air duct technology, offering high speed and low noise;

- Optimized oil circuit design for lower pressure loss and more energy-saving: Use optimized hydraulic principles and valve plate pipeline design to reduce oil pressure loss and improve energy-saving.

- Optimized oil circuit design for lower pressure loss and more energy-saving: Use optimized hydraulic principles and valve plate pipeline design to reduce oil pressure loss and improve energy-saving.

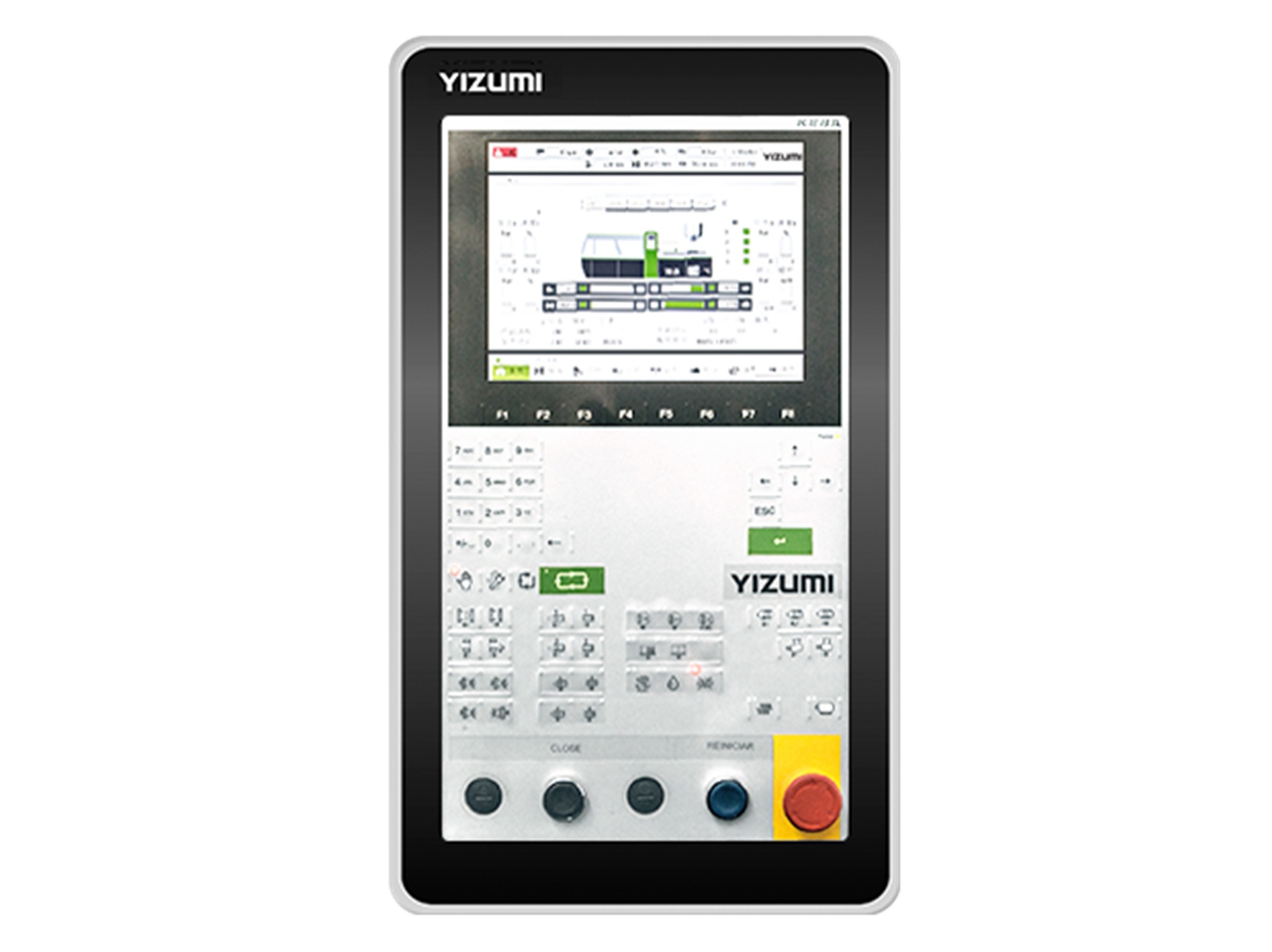

Control system with higher value

- Upgraded KEBA system;

- Expandable with multiple modules, including AO, AI, DO, DI, and T,M to meet more requirements;

- Real-time monitoring of signals from machine-equipped sensors to coordinate corresponding movements for higher operating safety;

- Support common RS232/485 communication interface, CANOPEN, Ethernet port, temperature compensation sensor connector, and USB port.

- Expandable with multiple modules, including AO, AI, DO, DI, and T,M to meet more requirements;

- Real-time monitoring of signals from machine-equipped sensors to coordinate corresponding movements for higher operating safety;

- Support common RS232/485 communication interface, CANOPEN, Ethernet port, temperature compensation sensor connector, and USB port.

Product Video

Industry Application

Relevant Recommendation

Relevant Products

Relevant Technologies

Relevant Automation

Service Process

01

Process/Mold Analyse and Design

- Raw materials selection

- Product design

- Mold flow analysis

- Mold design suggestion

02

Equipment Selection Suggestions

- Product performance

- Product quality

- Ease of use

- Safety requirements

03

Whole Plant Planning Advice

- Planning of production line

- Arrangements for people, machines, and materials according to process flow

- Peripheral automation

- Smart connection

04

Delivery Solutions

- Professional installation and debugging

- On-site operation training

- Molding process training

05

After Sales Solutions

- YFO services

- Preventive maintenance

- Device upgrade

Download

Contact Us

Please leave your message, and we will contact you soon!

I hereby give my consent for my personal data, collected and processed by YIZUMI in relation to my inquiry.

Contact Us

Please leave your message, and we will contact you soon!

I hereby give my consent for my personal data, collected and processed by YIZUMI in relation to my inquiry.