Energy-Saving Solutions for Rubber Injection Molding

Abstract:

Explore YIZUMI energy-saving rubber injection machine tech and rubber scrap recycling for sustainable manufacturing.

In today’s manufacturing landscape, energy efficiency is more than a cost-saving strategy—it’s a necessity for survival and sustainability. The rubber molding industry, traditionally known for high-temperature processing and long cycle times, is now under increasing pressure to adopt energy-saving technologies. For factories involved in rubber part manufacturing, from automotive seals to industrial gaskets, integrating YIZUMI energy-saving rubber injection machine?solutions can significantly improve profitability and sustainability.

Whether you’re looking to reduce energy costs, minimize environmental impact, or meet global green standards, upgrading your processes with advanced machinery and rubber scrap recycling technology?can help your factory remain competitive and forward-thinking.

The Need for Energy Efficiency in Rubber Injection Molding

Rubber injection molding is inherently energy-intensive. From the heating of molds and rubber materials to the operation of hydraulic systems, power consumption remains a major contributor to overhead costs. Additionally, rubber waste and material scrap generated during molding add to both environmental impact and financial loss.

Common energy-related challenges in rubber molding include:

l Long heating cycles

l Inconsistent temperature control

l Frequent machine downtime

l Excessive scrap due to material or dimensional inconsistency

The result? Increased electricity bills, more downtime, and wasted material that can no longer be ignored in a cost-conscious and eco-aware marketplace.

This is where the latest YIZUMI energy-saving rubber injection machine?innovations and rubber scrap recycling technology?become essential.

Five Energy-Saving Strategies for Rubber Injection Molding

1. Optimize Temperature and Pressure Control

Rubber molding requires precise control over both temperature and pressure. Any fluctuation results in defective products or longer cycle times. Advanced control systems such as PID-based feedback loops and real-time sensor monitoring ensure consistent mold temperature while reducing the energy required to maintain it.

Machines equipped with intelligent energy and temperature control—such as those offered by YIZUMI—can deliver up to 50% energy savings, thanks to more efficient heating and optimized hydraulics.

2. Integrate Servo-Hydraulic Systems

Traditional hydraulic systems waste energy during idle and low-load phases. By switching to servo-hydraulic or hybrid systems, energy is only consumed on-demand. This dynamic control dramatically reduces heat generation and electricity use.

For rubber molding, which requires forceful but infrequent hydraulic actuation, servo systems are particularly effective in reducing energy consumption while maintaining performance.

3. Minimize Rubber Waste Through Scrap Recycling

Rubber scrap is a significant concern in manufacturing. Without an effective recycling strategy, it adds to both disposal costs and environmental pollution. With modern rubber scrap recycling technology, manufacturers can reprocess leftover rubber into usable compounds, significantly improving material yield.

Rubber recycling systems often include:

l De-flashing units

l Waste collection conveyors

l Re-compounding systems

l Closed-loop rubber regeneration

By combining scrap management with precision molding, waste rates can be reduced to near zero—supporting sustainable manufacturing targets.

4. Implement Modular Machine Design

Modular machines allow the use of interchangeable components and custom setups for different mold requirements. This flexibility allows manufacturers to fine-tune machines for specific applications, improving cycle time and reducing energy consumption for jobs that don’t require full-capacity operation.

YIZUMI Energy-Saving Rubber Injection Machine: YL2-VL/F Asian Series

To truly optimize your energy efficiency goals, it’s essential to invest in machinery built from the ground up with sustainability and performance in mind. At YIZUMI, we’ve combined our core expertise in rubber, die-casting, and injection molding technology?with advanced energy management systems to create the YL2-VL/F Asian series.

Why Choose the YL2-VL/F Asian Series?

1. Designed for Compatibility and Efficiency

The high-bed structure of the YL2-VL/F Series aligns perfectly with traditional Asian mold designs. This means no costly mold redesigns and a smoother transition to newer, more energy-efficient machines.

2. Up to 50% Energy Savings

Our 3rd generation energy and temperature control system?enables energy savings of up to 50% for the entire machine. Whether you’re running large-batch industrial parts or custom automotive seals, this translates directly to cost reductions and greener operations.

3. Modular Flexibility

The modular design allows easy switching between different injection units and demolding devices. This is especially useful for rubber parts with varying complexity. It helps shorten setup times and makes operations more energy-efficient by avoiding unnecessary idle periods.

4. User-Friendly Operation and Maintenance

Every detail of the machine is built for convenience. The layout features a rear-mounted oil tank for better accessibility and more efficient use of floor space. The optimized piston installation structure?allows for quick disassembly and compound changes, minimizing downtime.

5. Cost-Effective and Industry Versatile

The YL2-VL/F Asian Series offers a high return on investment due to its cost-effectiveness, long operational life, and adaptability across multiple sectors, from automotive to industrial components.

With our focus on YIZUMI energy-saving rubber injection machine?development, we enable manufacturers to cut costs, improve uptime, and reduce their environmental footprint—all without compromising on molding precision or part quality.

The Future of Rubber Manufacturing: Automation + Recycling

Sustainable rubber manufacturing doesn’t stop at energy-efficient machines. Integrating automated handling?and rubber scrap recycling technology?is the next step toward achieving zero-waste production floors.

Automation in rubber molding can include:

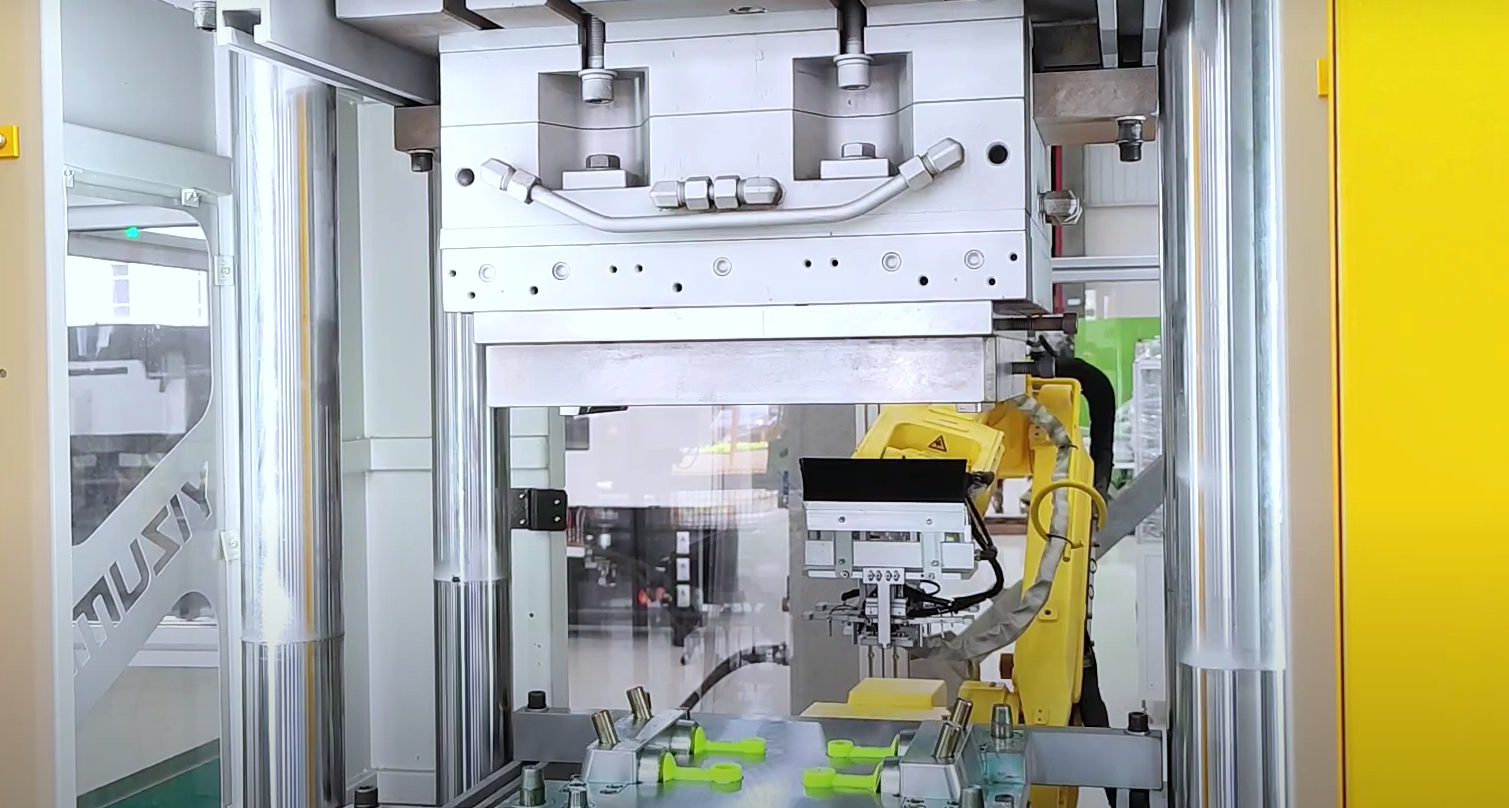

l Robotic part extraction

l Automated mold lubrication

l Vision-based quality inspection

l Smart part sorting

When paired with scrap handling and rubber re-compounding systems, this creates a closed-loop production system. Such systems not only reduce waste disposal but allow for material re-entry into the molding process—boosting overall resource efficiency.

FAQs

Q1: What kind of energy savings can I expect from switching to YIZUMI rubber injection machines?

A1: Our YL2-VL/F Asian Series delivers up to 50% energy savings, depending on production scale, material, and cycle configuration.

Q2: Is the machine compatible with existing molds?

A2: Yes. The high-bed structure of the YL2-VL/F Series is designed to work seamlessly with typical Asian molds, ensuring quick transition and reduced startup costs.

Q3: How does modular design benefit my operation?

A4: Modular components enable fast changes in tooling, injection units, or demolding systems—cutting downtime and improving adaptability for different rubber parts.

Q4: What industries use YIZUMI rubber injection machines?

A5: Our equipment is widely used in the automotive, electrical insulation, household appliances, and industrial sealing?sectors.

Smarter Energy Use for a More Sustainable Industry

As the manufacturing world evolves, energy efficiency, automation, and sustainability are no longer optional—they’re required. With rising costs and increasing environmental regulations, investing in efficient, modular, and reliable rubber injection solutions is the best move forward.

By choosing YIZUMI energy-saving rubber injection machine?solutions like the YL2-VL/F Asian Series, you are not only improving your factory’s profitability—you’re contributing to a greener and smarter manufacturing future. Combined with rubber scrap recycling technology, we provide you with a complete, future-proof solution tailored for long-term performance.

At YIZUMI, our mission is to offer integrated forming solutions that deliver on performance, innovation, and responsibility. We are more than a machine provider—we are your partner in transformation.