How to Optimize Two-Platen Injection Molding Machine Cycle Time for Mass Production

Abstract:

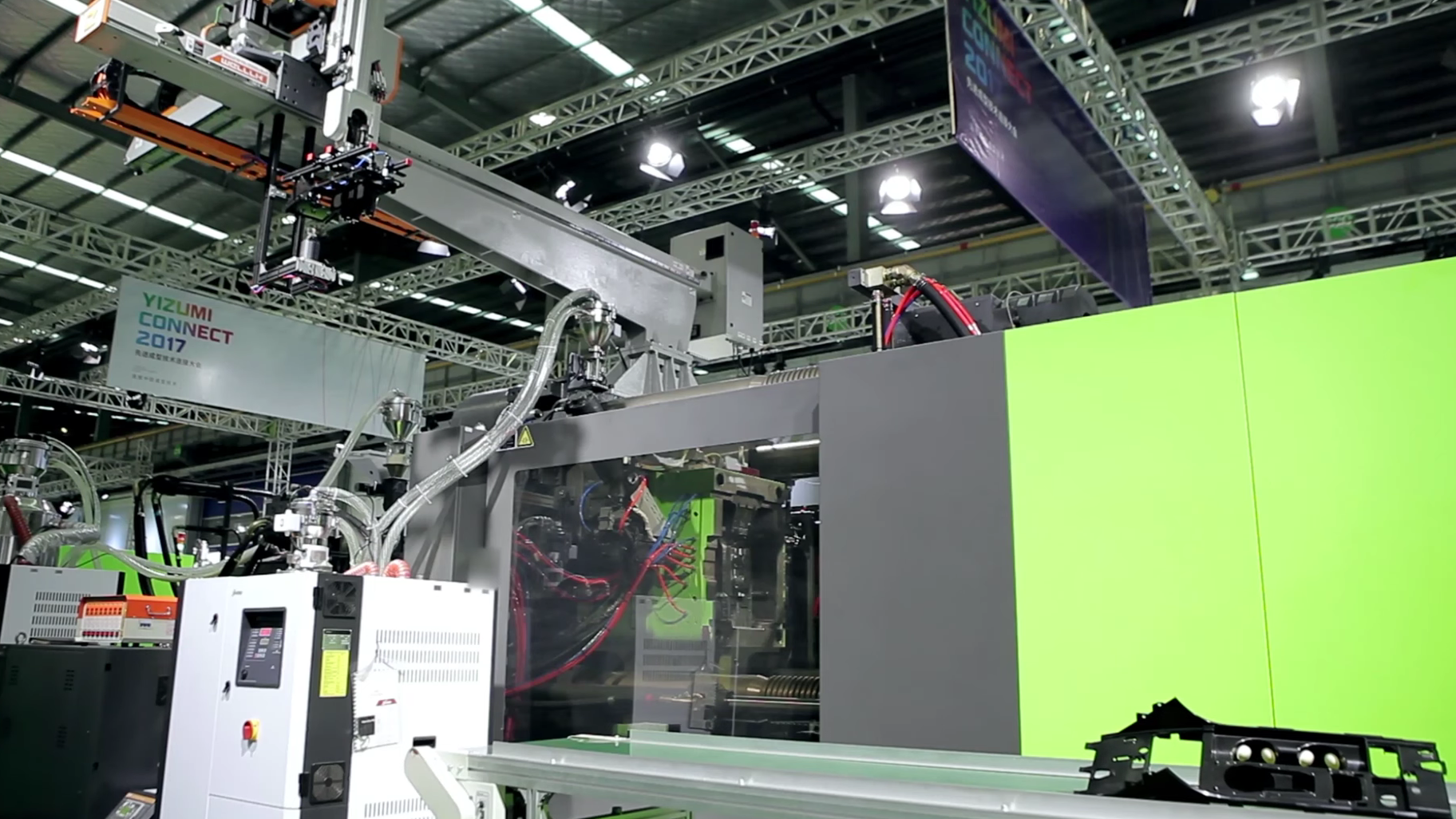

Learn how to optimize two-platen injection molding machine cycle time with YIZUMI solutions and automated robotic integration.

In the fast-paced world of mass manufacturing, efficiency?is everything. When high-volume production meets stringent quality requirements, manufacturers must rely on powerful and reliable equipment to maintain competitiveness. Among the most important tools in large-scale plastic part production is the two-platen injection molding machine. These machines offer unmatched advantages in space-saving, energy efficiency, and mold flexibility. However, without proper optimization, even the most advanced machine may fail to reach its full potential.

For companies looking to streamline processes, reduce cycle times, and increase overall profitability, mastering YIZUMI two-platen machine optimization?is essential. Especially in industries like automotive, home appliances, and logistics packaging—where the demand for precision and speed is constant—optimizing cycle time can directly impact cost-efficiency and market responsiveness.

Why Cycle Time Optimization Matters in Mass Production

The term “cycle time” refers to the total duration required to produce one molded part, including:

1. Mold closing

2. Injection

3. Cooling

4. Mold opening

5. Part ejection

Every second saved per cycle translates to thousands of additional parts produced annually—without extra labor, space, or overhead. In mass production, this directly improves profitability and throughput. Reducing cycle time also enhances machine availability and allows businesses to scale faster, especially when integrated with automated robotic integration?systems for part handling, in-mold labeling, or post-processing.

But optimizing the cycle time for two-platen injection molding machines?requires more than just speeding up operations. It demands a balance between speed, precision, safety, and energy consumption.

Core Strategies for Two-Platen Machine Cycle Time Optimization

1. Analyze and Minimize Dry Cycle Time

Dry cycle time (mold opening and closing without injection) is often overlooked. However, optimizing it brings immediate benefits. Advanced machines like YIZUMI’s D1 Series already offer up to 55% shorter dry cycle, making them ideal for time-sensitive operations. You can further enhance this by:

l Adjusting clamping speed parameters

l Reducing unnecessary mold stroke

l Calibrating mold open/close sensor positions

2. Use High-Speed Injection Settings with Control

The injection phase is crucial to cycle time. But simply increasing injection speed can lead to issues like short shots or flash. Instead, rely on:

l Servo-driven injection systems

l Ultrasonic displacement sensors for accurate positioning

l Real-time pressure monitoring and feedback loops

Advanced servo systems like those in the YIZUMI two-platen machine?range use fully oil-cooled two-headed motors. This not only boosts performance but ensures long-term stability in demanding environments.

3. Optimize Cooling with Mold Design and Temperature Control

Cooling usually consumes the largest portion of the cycle. Consider:

l Conformal cooling channel design

l Optimized water flow circuits

l Use of mold temperature controllers with adaptive PID control

With automated robotic integration, you can even initiate cooling cycles while parts are being removed or secondary processes are running, reducing idle times.

4. Integrate Intelligent Controls for Real-Time Adjustments

Modern production thrives on data. Smart control systems like the European KEBA Controller?on YIZUMI’s D1 Series support:

l Unlimited alarm and process logs

l SPC and PDP data tracking

l Customizable programming for unique applications like MuCell or IMC

This allows technicians to fine-tune settings instantly based on performance feedback, helping avoid downtime and maintain optimal cycle consistency.

Introducing the YIZUMI D1 Series Two-Platen Injection Molding Machine

When optimizing cycle time and performance is your goal, the YIZUMI D1 Series Two-Platen Injection Molding Machine?is the solution of choice. Designed for high-output manufacturing environments, this advanced equipment combines German engineering principles with our proprietary innovation in molding and automation.

What Makes the D1 Series Stand Out?

Unmatched Clamping Precision and Speed

l Our impact-proof synchronized lock nut mechanism?ensures fast and quiet mold closing.

l With ≤3% variation of force on the tie bar, you can trust your mold to maintain tight tolerances across millions of cycles.

l Shorter mold stroke and high-rigidity guide devices deliver reliable performance with minimal wear.

High-Precision Injection System

l Equipped with ultrasonic digital displacement sensors, the D1 Series minimizes signal interference while ensuring high-accuracy positioning.

l Our servo system, driven by a fully oil-cooled two-headed motor, ensures responsive movement, energy savings, and low thermal distortion.

l The adaptive PID temperature control supports consistent processing of various resins and complex part geometries.

Smart Automation-Ready Controls

l With the European KEBA controller, we offer robust process traceability, open integration capability for automated robotic integration, and full support for advanced molding processes.

l Whether you're managing multi-cavity molds, integrating in-mold assembly, or adapting to MuCell foaming or IMC decorative techniques, the D1 Series offers flexibility without cycle time trade-offs.

Our two-platen machines are engineered not only to reduce cycle time, but also to maintain stable output across 24/7 production schedules. When you choose YIZUMI, you’re choosing a partner committed to the complete molding solution—from machine to automation to service.

The Role of Robotic Integration in Cycle Time Optimization

Integrating robots into your two-platen injection molding line is no longer optional—it’s a competitive necessity. Robotic systems can:

l Extract parts faster than manual labor

l Handle hot parts with zero error

l Perform in-mold labeling or assembly

l Reduce human error and injury risk

Automated robotic integration?with machines like the D1 Series ensures seamless movement between stages, allowing for overlapping processes such as cooling and ejection or inspection and packaging.

Our machines are designed for easy robot arm installation and control integration, eliminating downtime during transitions and providing synchronized operations across all production stations.

Common Mistakes to Avoid When Reducing Cycle Time

While it’s tempting to speed up every function, this can lead to problems such as:

l Increased wear on mechanical parts

l Mold damage or flash

l Part warping or short shots

l Overheating of hydraulic systems

That’s why YIZUMI two-platen machine optimization?focuses on intelligent calibration rather than brute force. Our smart systems help users find the perfect balance between speed and precision—safeguarding both the equipment and product quality.

Smarter Optimization for Sustainable Manufacturing

In mass production, time truly is money. Optimizing your two-platen injection molding machine cycle time?isn’t just a way to produce more—it’s a strategy for staying ahead in an ultra-competitive manufacturing landscape.

With YIZUMI two-platen machine optimization?strategies, supported by advanced control systems and automated robotic integration, you gain the ability to maximize efficiency while minimizing risk. Our D1 Series?machines offer unmatched speed, precision, and digital integration, making them the ideal solution for businesses ready to scale and innovate.

At YIZUMI, we don’t just sell machines—we provide complete solutions. Our expertise in rubber, die casting, and injection molding allows us to support you at every step of the production journey. If your goal is smarter, faster, and more reliable mass production, we're ready to help you achieve it.