Exploring the Strengths of 3D Printing and Injection Molding

Abstract:

The manufacturing industry has witnessed remarkable advancements over the past few decades, with 3D printing and injection molding emerging as two of the most transformative technologies. Both have revolutionized how products are designed, prototyped, and produced, each offering distinct advantages depending on the specific requirements of a project.

The manufacturing industry has witnessed remarkable advancements over the past few decades, with 3D printing and injection molding emerging as two of the most transformative technologies. Both have revolutionized how products are designed, prototyped, and produced, each offering distinct advantages depending on the specific requirements of a project. 3D printing, with its ability to create complex, custom designs quickly and without the need for costly molds, excels in rapid prototyping and small-batch production. It allows for unparalleled flexibility, making it ideal for intricate, highly personalized products and one-off designs, often used in industries like aerospace, healthcare, and consumer goods.

On the other hand, injection molding continues to be the cornerstone of high-volume manufacturing. Known for its precision, repeatability, and ability to produce large quantities of identical parts, injection molding is indispensable in industries where consistent quality and efficiency are paramount. It is particularly suited for producing complex shapes with tight tolerances, such as those found in automotive, electronics, and medical device manufacturing. While 3D printing shines in customization and prototyping, injection molding is often the go-to solution when high-volume production is required, offering cost-effectiveness at scale and superior material properties.

Ultimately, the choice between 3D printing and injection molding depends on your production needs. For low-volume, intricate designs with high customization, 3D printing may be the best fit. For large-scale production of durable, high-precision parts, injection molding remains the preferred option. Understanding the strengths of each technology will enable manufacturers to make informed decisions based on their specific product goals and production constraints.

At YIZUMI, we integrate both technologies to provide tailored solutions for every project. Our SpaceA C-Line Industrial Pellet 3D Printing?and FF Series Electric Injection Molding Machine?represent the pinnacle of innovation, ensuring superior quality and efficiency.

3D Printing vs. Plastic Injection Molding

3D printing and plastic injection molding?are two key manufacturing technologies, each with unique advantages. 3D printing excels in rapid prototyping, customization, and producing complex designs without the need for molds, making it ideal for low-volume and intricate parts. In contrast, plastic injection molding is best suited for high-volume production, offering precision, repeatability, and cost-effectiveness in manufacturing identical parts. While 3D printing is favored for flexibility and innovation, injection molding remains the go-to choice for large-scale production with consistent quality. The decision between the two depends on factors such as volume, complexity, and material requirements.

Key Differences

Speed

1. 3D Printing: Suitable for rapid prototyping but slower for mass production.

2. Injection Molding: Ideal for high-speed, large-scale production runs.

Cost

1. 3D Printing: Low upfront cost, but higher per-unit cost for large quantities.

2. Injection Molding: Higher initial tooling investment but economical for mass production.

Precision

1. 3D Printing: Good for intricate designs but may lack the tight tolerances of injection molding.

2. Injection Molding: Excels in precision, repeatability, and consistency.

YIZUMI bridges these differences by offering advanced solutions in both fields. Whether you prioritize precision or flexibility, our products meet your unique requirements.

3D Printing Applications

3D printing?is revolutionizing industries by enabling:

· Rapid Prototyping: Quickly iterate designs without the need for molds.

· Complex Geometries: Create shapes that are difficult or impossible with traditional methods.

· Customization: Produce one-off or highly customized items with ease.

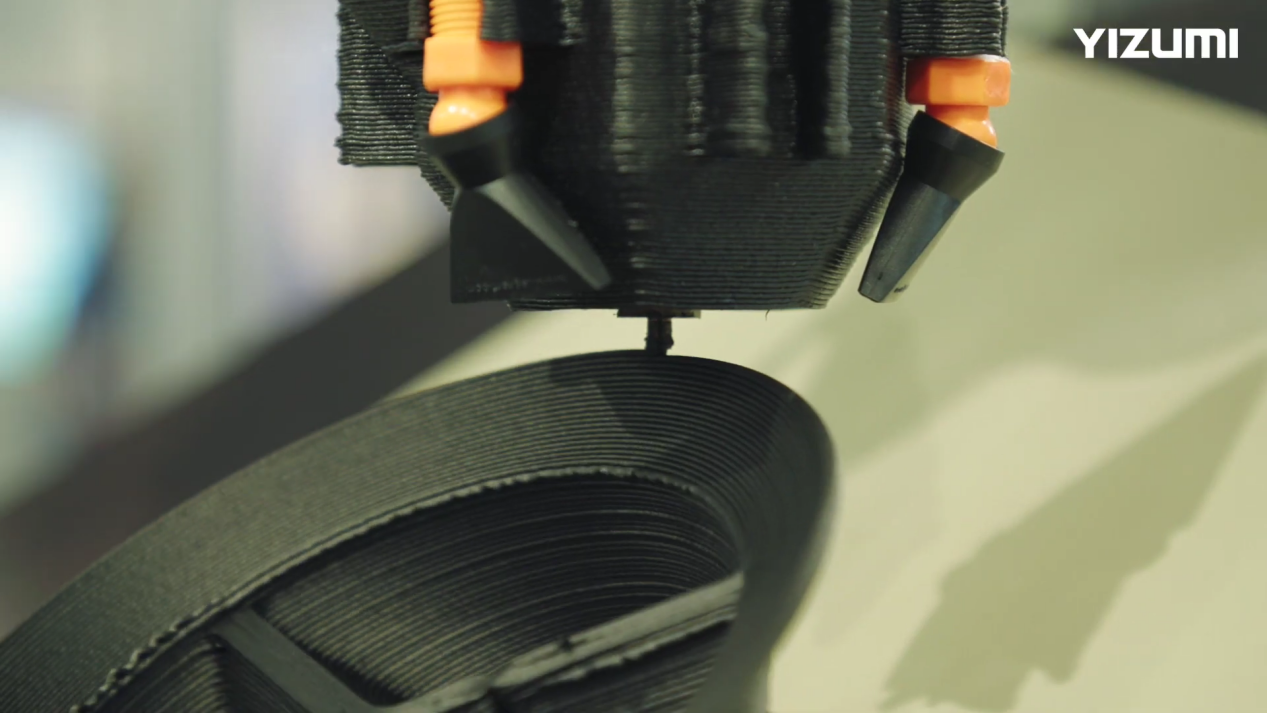

YIZUMI’s SpaceA C-Line Industrial Pellet 3D Printing?stands out for its:

· Integration of Printing and Milling: Enables hybrid production for enhanced versatility.

· Automation: Features like sensor integration and camera monitoring streamline industrial-level production.

· Precision: Positioning repeatability error ≤0.05mm ensures exceptional accuracy.

These capabilities make the SpaceA C-Line perfect for applications like functional prototypes, intricate components, and small-batch production.

Injection Molding Applications

Injection molding?remains a dominant technology for:

· Mass Production: High-volume manufacturing of uniform parts.

· Durability: Producing strong, reliable components with consistent quality.

· Precision: Ideal for complex parts requiring tight tolerances.

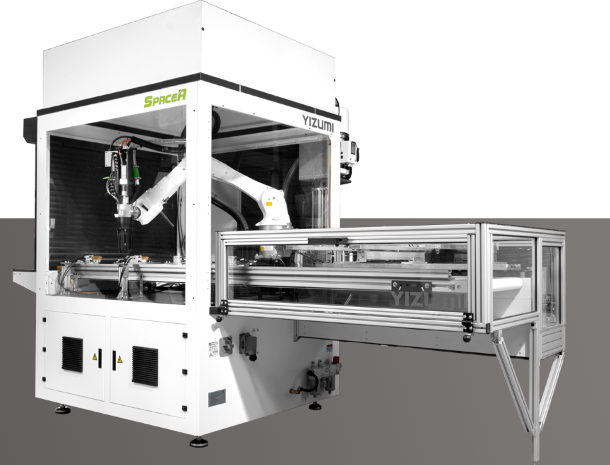

The FF Series Electric Injection Molding Machine?by YIZUMI takes this technology to the next level with:

· Dual-Cylinder Clamping Unit: Ensures uniform force application for precise mold release.

· Advanced Servo Control: Independent control of injection, clamping, and ejection for superior accuracy.

· Energy Efficiency: Up to 80% less energy consumption compared to traditional machines.

· European KEBA2000 Controller: Offers real-time monitoring, remote operation, and programmable features for seamless automation.

These features make the FF Series ideal for industries like automotive, electronics, and medical devices.

Advantages of Injection Molding Over 3D Printing

While 3D printing advantages?are undeniable, injection molding?offers distinct benefits:

1. Scalability: Injection molding is unbeatable for large-scale production.

2. Cost Efficiency: Lower cost per unit for mass manufacturing.

3. Material Versatility: Compatible with a wide range of plastics and composites.

4. Durability: Produces parts with superior strength and reliability.

YIZUMI’s FF Series Electric Injection Molding Machine?exemplifies these advantages, ensuring that manufacturers achieve maximum productivity and minimal waste.

Choose Custom Injection Molding or 3D Printing with YIZUMI

At YIZUMI, we recognize that no two projects are the same. Our dual expertise in 3D printing?and injection molding technology?allows us to provide tailored solutions:

For Prototyping and Customization

The SpaceA C-Line Industrial Pellet 3D Printing?system offers unmatched flexibility, making it ideal for creating prototypes or customized components.

For High-Volume Production

The FF Series Electric Injection Molding Machine?is perfect for mass-producing durable and precise components with tight tolerances.

Integrated Solutions

By combining the strengths of both technologies, we deliver hybrid solutions for complex manufacturing challenges.

Conclusion

So, is 3D printing better than injection molding? The answer depends on your needs. For customization, prototyping, or complex geometries, 3D printing advantages?are hard to beat. For scalability, cost-efficiency, and durability, the advantages of injection molding over 3D printing?are clear.

YIZUMI stands at the forefront of innovation, offering cutting-edge solutions in both technologies. Whether you need the flexibility of SpaceA C-Line Industrial Pellet 3D Printing?or the precision of the FF Series Electric Injection Molding Machine, we have the expertise and technology to meet your demands.

Reach out to YIZUMI?today to discover how we can help you achieve your manufacturing goals with our state-of-the-art equipment.