Quality Injection Molding Leads to Better Products

Abstract:

In today's competitive manufacturing landscape, quality injection molding plays a critical role in producing superior products that meet the increasingly high expectations of consumers. As industries evolve, so too does the demand for greater precision, efficiency, and consistency in plastic molding processes.

In today's competitive manufacturing landscape, quality injection molding plays a critical role in producing superior products that meet the increasingly high expectations of consumers. As industries evolve, so too does the demand for greater precision, efficiency, and consistency in plastic molding processes. Whether for medical devices, automotive components, or consumer goods, plastic injection molding machines are the backbone of modern manufacturing, enabling the production of high-quality, complex parts at scale. These machines offer unmatched repeatability, tight tolerances, and the ability to work with a wide range of materials, making them essential for industries that require durability, reliability, and cost-effective mass production. As manufacturing continues to advance, injection molding remains a cornerstone technology for companies striving to meet the growing demands of the market.

At YIZUMI, we specialize in delivering top-tier solutions through our P-M Series High-Speed Injection Molding Machine?and LSR Series Liquid Silicone Injection Molding Machine. These machines embody innovation, offering unmatched speed, precision, and efficiency for industries that prioritize quality.

Automation and Metal-to-Plastic Conversion

Automation is rapidly transforming how industries operate, and injection molding is no exception. Automated plastic molding processes significantly improve efficiency by ensuring consistent quality, reducing labor costs, and accelerating production timelines. With advanced robotic systems, manufacturers can streamline material handling, part removal, and packaging, all while minimizing human error. Additionally, the growing trend of converting metal components to plastic is revolutionizing various industries. This shift allows companies to reduce weight, cut material costs, and improve energy efficiency without compromising strength and durability. Industries such as automotive, aerospace, and electronics are increasingly adopting this approach, driving innovation and sustainability in product design and manufacturing processes. As automation and material innovation continue to evolve, plastic injection molding will remain a pivotal technology in modern manufacturing.

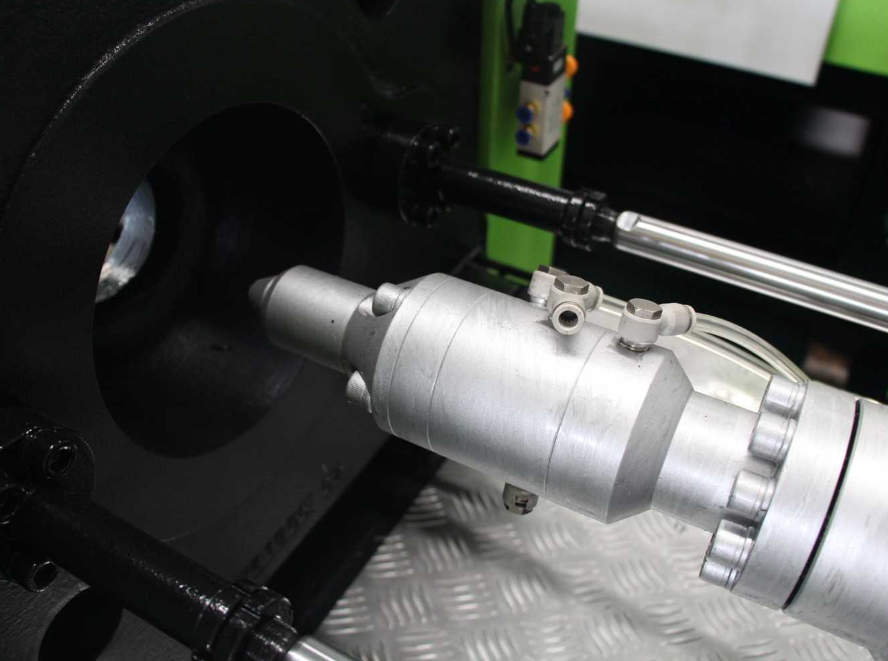

Our P-M Series High-Speed Injection Molding Machine?is designed to meet these demands. Its advanced single-cylinder injection system offers:

· High Speed: Maximum injection speeds of up to 500mm/s, ideal for demanding applications.

· Enhanced Stability: A high-strength toggle mechanism minimizes platen deformation, ensuring consistent product quality.

· Optional Electric Injection Unit: For synchronous plasticizing and improved precision.

This machine is perfect for industries undergoing metal-to-plastic conversion, enabling the production of lightweight yet durable components.

High-Quality Presses for Expertly Crafted Parts

Precision in injection molding directly impacts product quality. Superior presses like YIZUMI's LSR Series Liquid Silicone Injection Molding Machine?ensure uniformity and durability, especially for intricate and delicate parts.

The LSR Series?offers:

· Specialized Silicone Injection Unit: Precisely blends and vulcanizes materials for a flawless finish.

· Temperature Control: Built-in mold heating with visualized adjustments ensures stable curing.

· Mixing Screw for Silicone: Achieves perfect blending of silicone components A and B while minimizing issues like adhesion or yellowing.

From medical-grade silicone parts to automotive seals, the LSR Series?is designed to meet the highest standards of precision and reliability.

A One-Stop Shop for Injection Molding and Blow Molding Services

Many manufacturers today are seeking comprehensive solutions to optimize their plastic molding processes, aiming to enhance both efficiency and quality. YIZUMI offers a one-stop shop for a wide range of molding needs, providing both injection molding and blow molding technologies. By offering integrated solutions, YIZUMI enables businesses to streamline their operations, reduce lead times, and improve overall productivity. With advanced machinery and customized support, manufacturers can tackle diverse production challenges, from high-volume runs to complex, intricate designs. This holistic approach not only helps businesses reduce costs but also enhances flexibility, allowing them to meet the growing demands of the market with precision and speed.

Our P-M Series?caters to high-speed, high-precision applications, while the LSR Series?excels in handling advanced thermoset plastics like liquid silicone. With YIZUMI, you get access to cutting-edge technologies, expert guidance, and tailored solutions for your industry-specific needs.

Expert Plastic Molding Processes for Your Industry

Different industries demand specialized plastic molding processes?to meet their unique requirements.

Automotive:

o Lightweight components for fuel efficiency.

o Durable parts to withstand extreme conditions.

o Our P-M Series?ensures rapid production without compromising on strength.

Medical:

o Precision is critical for devices and implants.

o The LSR Series?provides unmatched accuracy and stability, ensuring compliance with medical-grade standards.

Consumer Goods:

o High-volume production with consistent quality.

o YIZUMI's machines reduce cycle times, enabling faster time-to-market.

Regardless of the industry, our machines are designed to optimize plastic injection molding processes, delivering superior results across a wide range of applications. Whether producing high-precision medical components, durable automotive parts, or complex consumer products, our machines offer enhanced efficiency, consistent quality, and greater flexibility. By incorporating advanced technology and innovative features, we ensure that each molding cycle is streamlined for maximum productivity, reduced waste, and improved cost-effectiveness. This results in higher-quality products that meet the specific demands of each industry, all while maintaining the ability to adapt to evolving manufacturing needs.

YIZUMI's Quality Injection Molding Machines

YIZUMI's mission is to redefine quality injection molding?through continuous innovation. Our P-M Series High-Speed Injection Molding Machine?and LSR Series Liquid Silicone Injection Molding Machine?exemplify our commitment to excellence.

Why Choose the P-M Series?

· Efficiency: Optimized for high-speed production in cleanroom environments.

· Durability: High-rigidity clamping unit extends service life and protects molds.

· Versatility: Suitable for large-diameter or deep-cavity products, offering consistent performance across various applications.

Why Choose the LSR Series?

· Precision: Tailored for liquid silicone, ensuring uniform mixing and curing.

· Innovation: Features like the pneumatic injection nozzle and auxiliary equipment improve usability and reduce waste.

· Reliability: Delivers consistent quality with low maintenance requirements.

With YIZUMI, you gain access to not only advanced machinery but also a partner committed to your success.

Conclusion

The importance of quality injection molding?cannot be overstated. As industries evolve, so do their demands for precision, efficiency, and scalability. Whether you need advanced solutions for high-speed production or intricate silicone components, YIZUMI has you covered.

Our plastic injection molding machines, including the P-M Series?and LSR Series, are engineered to meet the diverse needs of modern manufacturing.

By choosing YIZUMI, you invest in state-of-the-art technology, expert support, and unparalleled performance.

Let us help you elevate your plastic molding processes?and deliver products that set new standards of quality. Reach out today to learn more about our innovative solutions.