Why Choose Multi-Component Injection Molding Machines for Complex Parts

Abstract:

Choosing a multi-component injection molding machine is more than an equipment upgrade—it’s a step toward higher efficiency, lower costs, and greater design possibilities. For manufacturers in automotive, medical, and consumer electronics, investing in the right solution ensures competitiveness in a demanding global market.

Nowadays, manufacturers across industries are under increasing pressure to deliver products that are lighter, stronger, and more sophisticated in function—all while controlling production costs. Traditional single-material molding can be limiting when designing complex parts that require multiple materials, colors, or functions. This is where the multi-component injection molding machine proves its value.

By allowing two or more materials or colors to be molded in a single process, multi-component injection molding offers a solution for producing high-precision, durable, and aesthetically refined parts. For businesses in automotive, medical, and consumer electronics, these machines open the door to design flexibility and higher productivity.

Multi-Component Injection Molding: Take A Closer Look

A multi-component injection molding machine is designed to process multiple materials or colors into a single molded part. Also known as two-shot molding or multi-material injection molding, the process involves sequential or simultaneous injection of different plastics to form a finished component.

Instead of molding separate parts and assembling them later, manufacturers can integrate multiple materials in a single cycle. This saves time, improves structural integrity, and ensures seamless bonding between materials. The result is complex products with reduced defects and improved performance.

Multi-component Injection Molding Solutions

Why Businesses Are Choosing Multi-Component Injection Molding Machines

1. Improved Product Design and Functionality

With the ability to mold different materials into one part, designers can combine hard and soft plastics, transparent and opaque layers, or multiple colors. This enables functional enhancements like built-in seals, ergonomic grips, or transparent windows—without secondary processes.

2. Reduced Production Costs

By eliminating post-molding assembly, manufacturers cut down on labor, adhesive usage, and quality inspection time. Fewer process steps translate into faster lead times and a more efficient production cycle.

3. Consistency and Precision

Because all materials are molded in one cycle, dimensional accuracy is greatly improved. This ensures better repeatability, less material waste, and reduced chances of misalignment or part failure.

4. Durability and Stronger Bonding

Multi-component molding creates a molecular bond between materials, resulting in longer-lasting and more reliable products compared to those joined through adhesives or mechanical fasteners.

5. Sustainability Advantages

With fewer secondary operations and energy-efficient production, businesses can reduce their carbon footprint and align with green manufacturing initiatives.

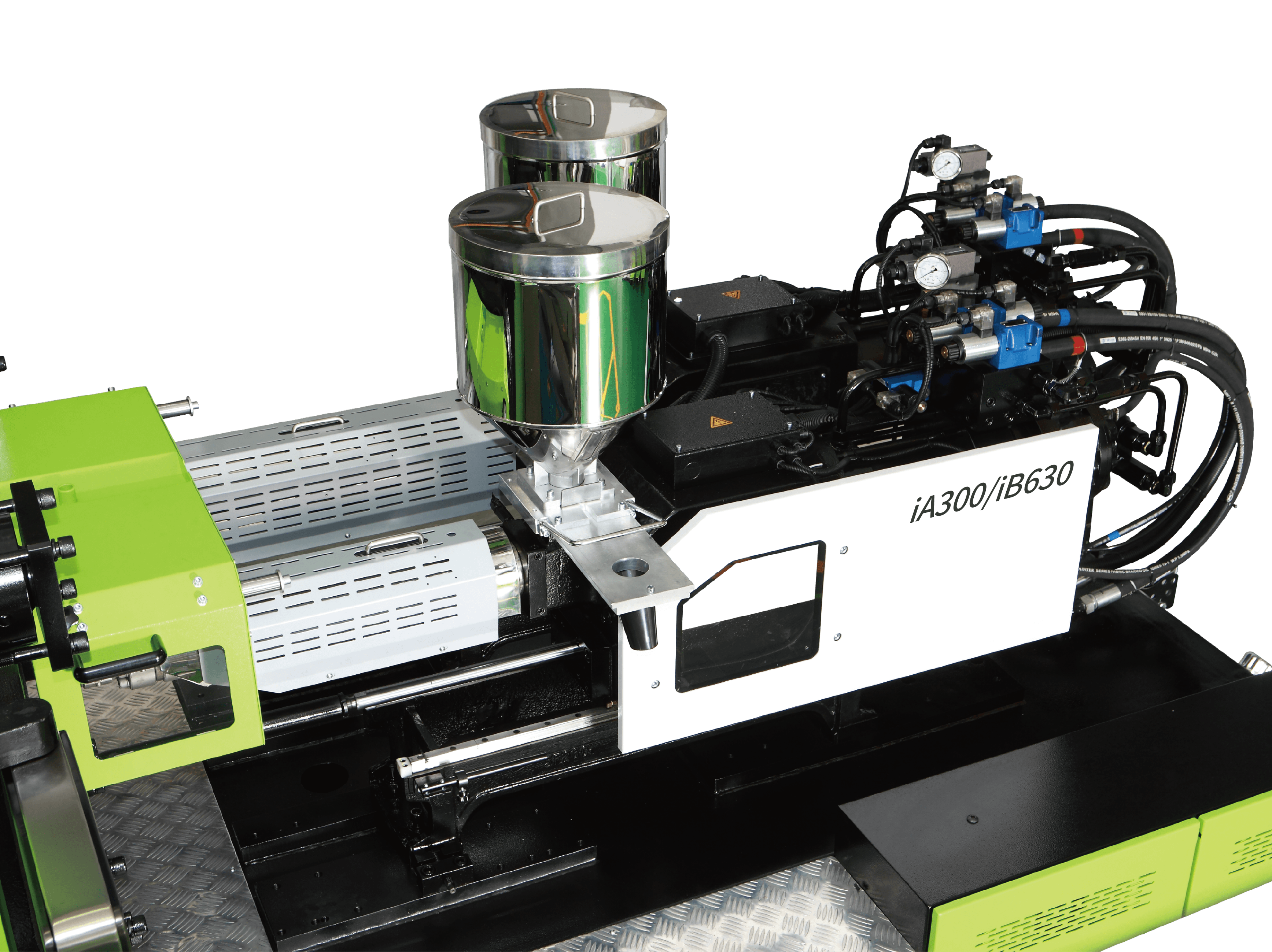

Modular injection unit combination

Applications of Multi-Component Injection Molding Machines

Multi-component injection molding is being rapidly adopted across industries where complex, high-performance parts are required, addressing critical challenges such as design flexibility, cost efficiency, and product durability:

Automotive: With the push for lighter, safer, and more stylish vehicles, automakers need seamless integration of soft-touch trims, durable seals, multi-color dashboards, and functional switches. Multi-component molding eliminates secondary assembly, reducing costs and improving reliability.

Medical Devices: In healthcare, precision and safety are paramount. Multi-material syringes, ergonomic surgical grips, and housings with transparent covers ensure biocompatibility, functionality, and user comfort—all in a single molding process that minimizes contamination risks.

Consumer Electronics (3C): Devices like smartphones and wearables demand compact, sleek designs with high durability. Multi-component injection molding enables the precise production of casings, connectors, and buttons that combine aesthetics, strength, and functionality in one process.

Home Appliances: Consumers expect modern appliances to combine performance with user-friendly design. Handles, control panels, and functional parts made with multi-material molding provide durability, better tactile feel, and enhanced product appeal.

These applications highlight how multi-component injection molding machines not only improve product quality but also solve industry-specific pain points such as cost reduction, safety compliance, miniaturization, and design innovation—making them indispensable in modern manufacturing.

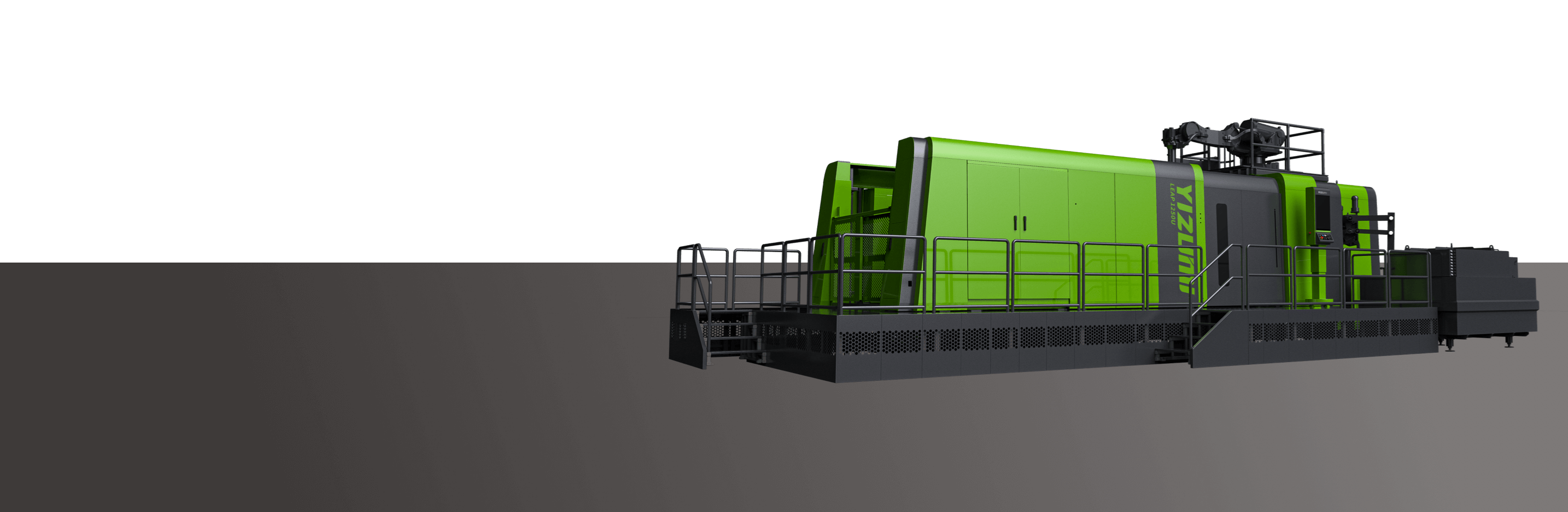

YIZUMI Multi-Component Injection Molding Machines

When businesses evaluate an investment in advanced molding equipment, they look for reliability, precision, flexibility, and long-term value. YIZUMI’s CE-P Series high-end electric multi-component injection molding machine addresses all of these needs while supporting industries where performance cannot be compromised.

YIZUMI Multi-component Injection Molding Machine

Advanced Clamping Technology

The CE-P Series is built on a European platen design concept, offering higher rigidity and precise force analysis. With YIZUMI’s Balanced Force Clamping (BFC) technology, force is evenly distributed across the mold, ensuring longer mold life, stable molding quality, and fewer flashes.

Intelligent Turntable Control

Featuring the third-generation digital closed-loop positioning control (DCPC) technology, the machine’s turntable operates with fast speed and exceptional accuracy. This reduces cycle times, enhances reliability, and improves overall molding stability.

High-Precision Injection Performance

Equipped with world-class position sensors and Linear Guide Support (LGS) technology, the injection unit minimizes friction and provides unmatched repeatability. Weight consistency reaches up to 1‰, meeting the high standards of industries such as medical and electronics.

Energy Efficiency and Low-Carbon Design

The machine integrates low-carbon insulation and precise temperature control systems, which not only reduce energy consumption but also maintain stable processing. This aligns with the growing demand for sustainable production methods.

Two-color Molding Solution For Electroplated Car Interior Trim

Smart, User-Friendly System

With an intelligent clamping management system, operators can monitor and optimize clamping force in real time, saving energy and improving mold protection. The machine also supports seamless integration with robots, MES, and other automation systems, ensuring compatibility with Industry 4.0 environments.

Flexible Injection Units

The independent L and V injection units provide the flexibility to combine modules based on production needs and machine tonnage. This modular approach supports a wide range of applications, from small medical components to large automotive parts.

In short, the CE-P Series multi-component injection molding machine embodies YIZUMI’s strengths: advanced technology, reliability, and adaptability for industries that demand high-performance molding.

Conclusion

Choosing a multi-component injection molding machine is more than an equipment upgrade—it’s a step toward higher efficiency, lower costs, and greater design possibilities. For manufacturers in automotive, medical, and consumer electronics, investing in the right solution ensures competitiveness in a demanding global market.

YIZUMI’s CE-P Series high-end electric multi-component injection molding machine offers the technology, precision, and flexibility businesses need to manufacture complex parts with confidence. If you’re looking for a partner to support your molding projects with advanced, reliable, and efficient solutions, YIZUMI is ready to help!