Top 5 Benefits of Integrated Die Casting in Modern Manufacturing

Abstract:

In today's highly competitive manufacturing landscape, efficiency, precision, and cost-effectiveness are critical factors for success. Integrated die casting has emerged as a leading technology driving these advantages for manufacturers worldwide. As a professional manufacturer and supplier of advanced injection molding and die casting machines, YIZUMI understands the growing demand for integrated die casting solutions. This article explores the top benefits of integrated die casting and why it is becoming a preferred method in modern manufacturing processes.

In today’s highly competitive manufacturing landscape, efficiency, precision, and cost-effectiveness are critical factors for success. Integrated die casting has emerged as a leading technology driving these advantages for manufacturers worldwide. As a professional manufacturer and supplier of advanced injection molding and die casting machines, YIZUMI understands the growing demand for integrated die casting solutions. This article explores the top benefits of integrated die casting and why it is becoming a preferred method in modern manufacturing processes.

What is Integrated Die Casting?

Integrated die casting refers to the seamless combination of die casting with additional manufacturing processes such as trimming, machining, or assembly within a single automated system. Unlike traditional die casting, where components are cast first and then sent to separate stations for finishing, integrated die casting optimizes the entire production line by consolidating these steps. This integration reduces cycle times, improves product quality, and enhances operational efficiency.

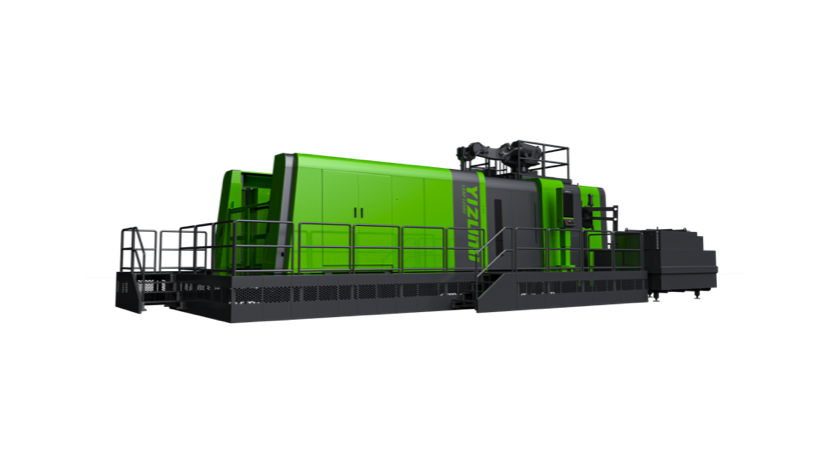

Die casting Machine Manufacturer

1. Enhanced Production Efficiency

One of the most significant advantages of integrated die casting is the improvement in production efficiency. By combining multiple stages of manufacturing into a single workflow, manufacturers can reduce the handling and transfer time of parts between processes. This not only speeds up production but also minimizes the risk of damage or defects that might occur during transportation or manual handling.

Automated integrated die casting systems can operate continuously with minimal downtime, ensuring higher throughput and more consistent output. This makes integrated die casting ideal for high-volume manufacturing environments where meeting tight deadlines is crucial.

2. Superior Product Quality and Precision

Integrated die casting machines are engineered to deliver high precision and consistent quality. The integration of secondary processes such as trimming or machining within the die casting machine ensures that each component is finished accurately and uniformly. This reduces variability and defects caused by manual interventions or multiple setups.

The controlled environment within integrated systems also allows better management of temperature, pressure, and other critical parameters, resulting in stronger, more dimensionally stable parts. Manufacturers benefit from lower scrap rates and enhanced performance of final products, especially in industries like automotive, aerospace, and electronics, where quality is paramount.

3. Cost Savings Across the Manufacturing Process

While integrated die casting systems may require a higher initial investment, the long-term cost savings are significant. Reduced labor costs, lower scrap rates, and shortened production cycles all contribute to improved cost-efficiency.

Additionally, integrated die casting reduces the need for multiple pieces of equipment and extensive floor space, lowering overhead costs. The consolidation of processes also simplifies workflow management and decreases the likelihood of production delays or errors, resulting in better overall cost control.

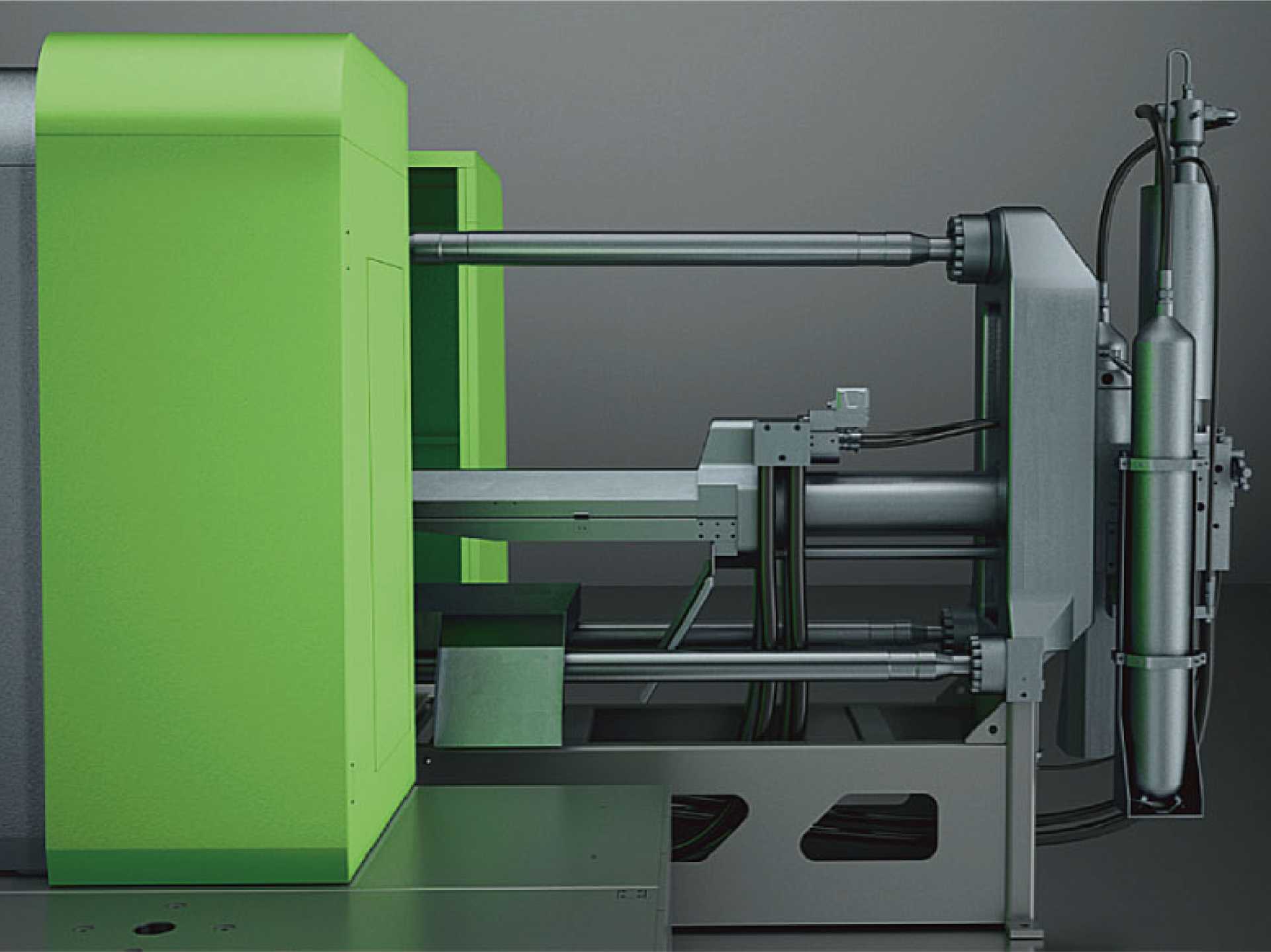

LEAP Series Die Casting Machine Injection Unit

4. Flexibility and Customization

Modern integrated die casting machines come with advanced control systems that allow for quick changeovers and easy customization. Manufacturers can adjust parameters or switch between different molds and production setups without extensive downtime.

This flexibility is especially valuable for producing complex parts or limited production runs where traditional die casting might be less efficient. Integrated die casting machines enable manufacturers to respond rapidly to changing market demands or customer specifications without compromising quality or efficiency.

5. Environmental and Energy Benefits

Integrated die casting technology supports sustainable manufacturing practices by reducing waste and energy consumption. The streamlined process minimizes material usage and rejects, which translates to less scrap metal and lower raw material costs.

Moreover, integrated systems are designed to be energy-efficient, with optimized heating and cooling cycles that reduce electricity consumption. Many modern integrated die casting machines comply with international environmental standards, helping manufacturers meet increasingly stringent regulatory requirements.

LEAP Series Die Casting Machine: Precision, Efficiency, and Innovation

The LEAP Series Die Casting Machine by YIZUMI represents the pinnacle of modern die casting technology, combining advanced engineering with user-centric design to meet the evolving demands of industries such as automotive, aerospace, and electronics. Designed to deliver superior casting precision and repeatability, the LEAP series is engineered for high-performance applications requiring complex and large-scale components.

LEAP Series Die Casting Machine

Key Features and Benefits

1. Advanced Injection Control with Yi-Cast Technology

At the heart of the LEAP Series is the Yi-Cast real-time closed-loop injection system. This proprietary technology offers self-learning capabilities that adapt to process variations, ensuring consistent shot-to-shot quality. By dynamically adjusting injection parameters, Yi-Cast minimizes defects such as flash and cold shuts, enhancing the overall quality of the castings.

2. ORCA Control System: Intuitive and Efficient

The ORCA control system provides an intuitive human-machine interface (HMI) that simplifies machine operation and process monitoring. Its graphical display and multi-touch functionality enable operators to easily set parameters, monitor performance, and troubleshoot issues, reducing training time and improving operational efficiency.

3. Energy-Efficient Hydraulic Drive

The LEAP Series incorporates an innovative two-stage hydraulic drive system that reduces energy consumption by up to 40% compared to conventional systems. This energy efficiency not only lowers operational costs but also contributes to a more sustainable manufacturing process. The system's design also extends the service life of hydraulic components, ensuring long-term reliability.

4. High-Speed Clamping System

Equipped with a reinforced toggle system, the LEAP Series achieves faster closing and opening times, enhancing cycle time efficiency. The system's rigidity ensures stable die locking, even under high-pressure conditions, which is crucial for producing complex and large components without deformation.

5. Versatility Across Applications

The LEAP Series is available in clamping forces ranging from 380T to 5000T, making it suitable for a wide range of applications, from small precision parts to large structural components. Its versatility allows manufacturers to produce a variety of products with consistent quality and efficiency.

YIZUMI LEAP Series Die Casting Machine

Applications

The LEAP Series is ideal for producing complex aluminum and magnesium die castings, including:

Automotive Components: Structural parts, engine blocks, and transmission housings.

Aerospace Parts: Lightweight structural components and housings.

Electronics Enclosures: Heat sinks and protective casings.

Industrial Machinery: Frames and housings requiring high strength and precision.

The LEAP Series Die Casting Machine by YIZUMI sets a new standard in die casting technology, offering manufacturers a solution that combines precision, efficiency, and versatility. With its advanced features and robust design, the LEAP Series is an investment that drives productivity and quality in modern manufacturing environments.

Conclusion

Integrated die casting is transforming modern manufacturing by enhancing efficiency, improving product quality, and reducing costs. Its ability to combine multiple manufacturing steps into a single, automated process makes it a smart investment for manufacturers seeking to stay competitive in the global market.

For companies looking to adopt integrated die casting, partnering with an experienced die casting machine supplier like YIZUMI ensures access to the latest technology and expert support. Explore how integrated die casting can elevate your manufacturing capabilities and drive business growth.