Custom Servo Injection Molding Machine Solutions for High-Volume Production

Abstract:

In today's fast-paced manufacturing landscape, high-volume production demands precision, energy efficiency, and reliability. For businesses in the plastics industry, investing in the right injection molding solution can make all the difference in productivity and product consistency. A custom servo injection molding machine is engineered to meet the unique demands of mass production while offering flexibility, efficiency, and cost control.

In today's fast-paced manufacturing landscape, high-volume production demands precision, energy efficiency, and reliability. For businesses in the plastics industry, investing in the right injection molding solution can make all the difference in productivity and product consistency. A custom servo injection molding machine is engineered to meet the unique demands of mass production while offering flexibility, efficiency, and cost control.

What Is an Injection Molding Machine?

An injection molding machine is a manufacturing system designed to shape plastic materials by injecting molten resin into a mold. This process is widely used across various industries such as automotive, consumer electronics, medical devices, packaging, and more. The machine comprises key components like an injection unit, a clamping unit, a mold, and a control system.

But when production scales up, the choice of machine type becomes even more critical. That’s where servo injection molding machines enter the spotlight.

Servo Injection Molding Machine Manufacturer

Why Choose a Servo Injection Molding Machine?

A servo injection molding machine uses servo motors to control hydraulic flow or all-electric movements. Unlike traditional hydraulic machines, servo models deliver precise, energy-efficient, and quiet operation. They adjust motor output based on load demand, significantly reducing energy consumption—often by up to 60%.

Key Benefits:

- Energy Efficiency: Servo motors consume energy only when needed, cutting down electricity costs.

- Precision Control: They ensure repeatability and consistency in complex molding operations.

- Faster Cycle Times: Improved responsiveness leads to shorter cycles and higher throughput.

- Lower Operating Noise: Quieter operations help improve the working environment.

- Reduced Maintenance: Fewer moving parts and adaptive control systems lead to less wear and longer machine life.

The Role of Customization in High-Volume Production

High-volume production is rarely a one-size-fits-all process. Different industries require different molding techniques, materials, clamping forces, and shot sizes. Customized servo injection molding machines offer tailored solutions that align with specific product designs, tolerances, and production goals.

Customization Options May Include:

- Clamping Force Ranges: Optimized for thin-wall or high-pressure applications.

- Multi-component Molding: For producing parts with multiple materials or colors.

- Integrated Automation: Including robotic arms, conveyors, and in-mold labeling systems.

- Advanced Control Interfaces: Touchscreen HMIs with AI-powered production monitoring.

- Smart Manufacturing Compatibility: Integration with MES, SCADA, or ERP systems.

By customizing a servo injection molding machine, manufacturers can achieve a more streamlined process, lower material waste, and reduce cycle time—all of which contribute to a more competitive production line.

Plastic Injection Molding For Bucket Lids

Why Servo Injection Molding Machines Are Ideal for High-Volume Production

When operating at large scales, every second saved in a cycle, and every gram of material conserved, can result in significant cost reductions. Servo injection molding machines deliver on three critical fronts:

1. Efficiency at Scale

In high-volume environments, energy savings translate directly into profitability. Servo machines precisely manage motor speed and torque, ensuring energy is used only when necessary.

2. Consistent Quality

Part-to-part consistency is vital in sectors like medical, packaging, and automotive. Servo control systems provide better stability in pressure and temperature, minimizing defects and improving product uniformity.

3. Lower Total Cost of Ownership

While initial investment might be higher than traditional hydraulic models, the lower operating costs, reduced downtime, and minimized scrap rate result in a significantly lower total cost over the machine’s lifecycle.

Choosing the Right Servo Injection Molding Machine

Before selecting a machine, consider:

- Your part size and geometry.

- Required shot weight and cycle time.

- Type of resin or materials used.

- Degree of automation and integration with existing systems.

- Budget and ROI timeframe.

Working with a professional injection molding machine manufacturer like YIZUMI ensures you receive expert consultation, machine testing, and production optimization support.

A5-EU Series High-End Servo Injection Molding Machine: Engineered for Precision & Performance

For manufacturers seeking a robust and reliable solution for high-volume plastic part production, the A5-EU Series high-end servo injection molding machine delivers outstanding performance, repeatability, and energy efficiency. With clamping forces ranging from 300 to 7,000 kN, this advanced model is purpose-built to meet the evolving needs of industries such as automotive, packaging, consumer goods, and medical.

Key Features at a Glance:

- Precise and Stable: Optimized for consistent part quality and process repeatability.

- Reliable and Durable: Designed with a high-rigidity frame and quality components.

- High Efficiency and Energy Saving: Equipped with Yizumi’s third-generation servo system.

- User-Friendly Operation: Powered by the KEBA control system with an intuitive interface.

High-end Servo Injection Molding Machine

Clamping Unit: Stability Reinvented

The A5-EU series high-end servo injection molding machine features a stable, high-rigidity clamping system designed with European-standard T-slot platens. This structure enhances parallelism and minimizes platen deformation, significantly improving the repeatability of clamping force. The rigid machine frame and high-grade manufacturing processes further contribute to long-term operational stability.

- EUROMAP 2 Compliant: Ejector hole patterns and mold location holes conform to EUROMAP 2 standards for enhanced mold compatibility.

- Enhanced for High-Speed, High-Pressure Molding: Designed to support demanding injection molding applications, especially where dimensional accuracy and cycle consistency are critical.

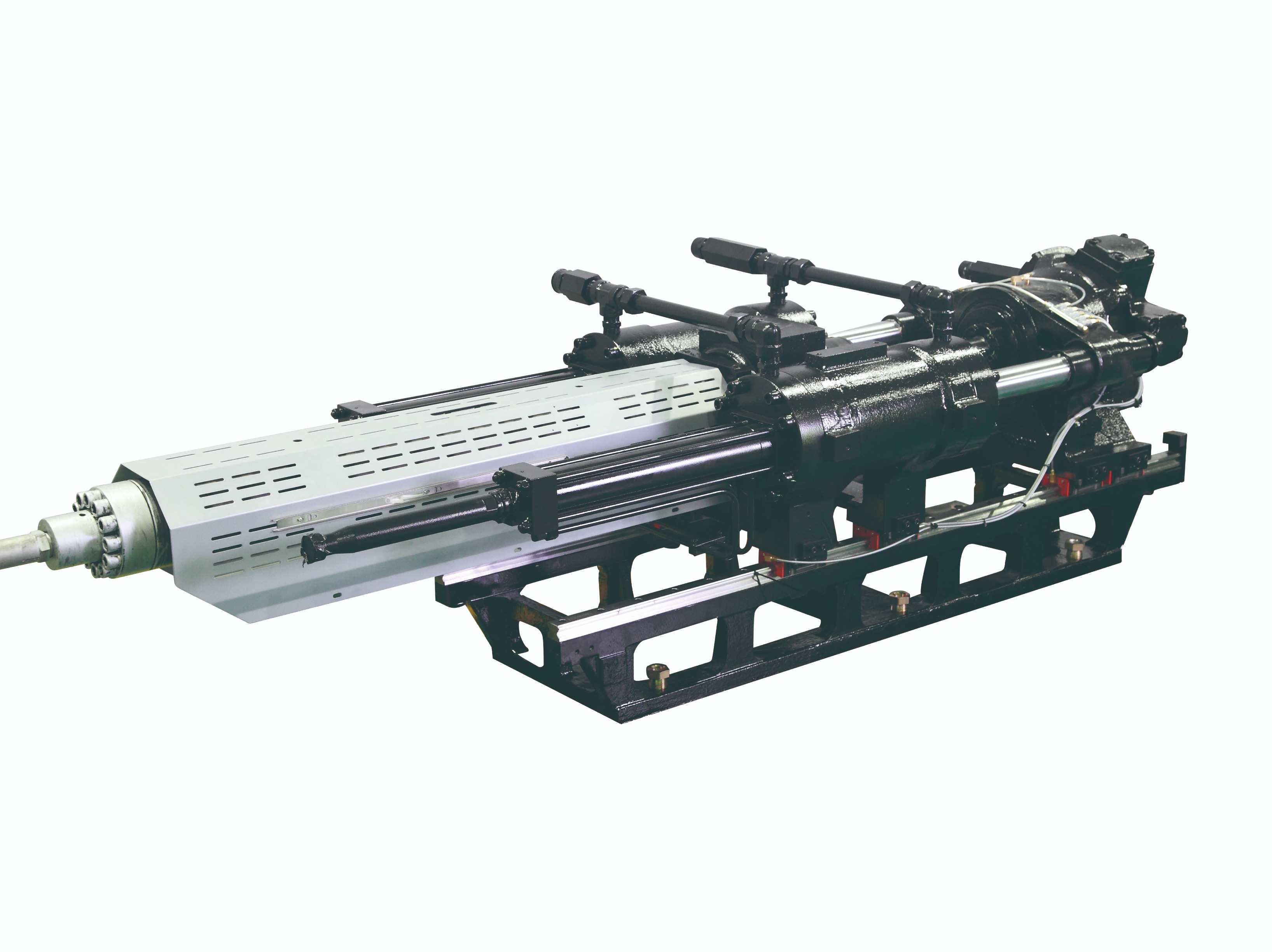

Injection Unit: Built for Accuracy

The A5-EU adopts an integrated linear guide rail support system and a dual-cylinder injection structure to ensure smooth and precise movements. This configuration minimizes friction and supports consistent, high-speed injection.

- Proportional Back Pressure Control: Enables accurate control during plasticizing for better material flow and part consistency.

- Injection Frame Compatibility: The machine can be equipped with injection units of varying sizes, thanks to pre-drilled mounting points—offering flexibility for different molding requirements.

Injection Unit For Plastic Injection Molding

Advanced Servo System: Performance Meets Efficiency

The third-generation energy-saving servo technology in the A5-EU series high-end servo injection molding machine has been extensively refined. Upgrades in motor structure, magnetic materials, oil pump selection, and drive software result in superior control and performance.

- Energy Savings: Uses 30% to 80% less energy compared to conventional hydraulic machines.

- Low Noise and High Durability: Engineered for long-term use with reduced operating sound levels and minimal maintenance needs.

High-Precision Control System

The A5-EU is powered by Austria’s KEBA control system, delivering responsive control and advanced process management.

- 10” True Color Touchscreen: With a user-friendly interface and fast processing speeds.

- Flexible Connectivity: USB ports for mold data backup, CF card storage, and expandable I/O modules for temperature and valve control.

- Smart Integration: Interfaces for printers, auxiliary equipment, and automation components enable seamless factory integration.

Injection Molding For Automotive Light Guide Block

Industry Applications of Servo Injection Molding Machines

YIZUMI's servo injection molding solutions are used across various industries that rely on high-volume precision manufacturing:

- Automotive: Complex components such as bumpers, dashboards, and connectors.

- Medical: High-precision parts for syringes, IV components, and diagnostics equipment.

- Consumer Electronics: Housings for phones, laptops, and wearable devices.

- Packaging: Thin-wall containers, closures, and biodegradable packaging solutions.

- Household Appliances: Durable plastic enclosures, knobs, and fasteners.

Each of these sectors demands reliability and tight tolerance control, making servo systems a preferred choice.

Conclusion

In the competitive world of high-volume plastic manufacturing, choosing the right equipment is crucial. A custom servo injection molding machine offers a smart, scalable, and cost-effective way to meet modern production challenges. With high energy efficiency, precise control, and customizability, these machines are the backbone of next-generation manufacturing.

If you're planning to upgrade your production line or launch a new product series, YIZUMI can help you design and implement the ideal servo injection molding solution for your business. Contact us today to discuss your custom requirements and take your production capabilities to the next level!