Top Four Common Defects in High-Pressure Die Casting Process

Abstract:

High-pressure die casting is an efficient manufacturing process used to create precise, durable metal components, especially in industries like automotive and aerospace. In this process, molten metal (such as aluminum, zinc, or magnesium) is injected into a steel mold under high pressure (1,000 to 25,000 psi).

High-pressure die casting is an efficient manufacturing process used to create precise, durable metal components, especially in industries like automotive and aerospace. In this process, molten metal (such as aluminum, zinc, or magnesium) is injected into a steel mold under high pressure (1,000 to 25,000 psi). This pressure ensures the metal fills every detail of the mold, producing complex shapes with high accuracy. The metal solidifies quickly, and the mold is opened to eject the finished part, often with minimal post-processing required. The process results in strong, durable parts with smooth surfaces, ideal for high-volume production.

However, defects like porosity, cold shuts, flash, and incomplete filling can occur, affecting the quality and efficiency of production. These issues may arise from factors such as poor mold design, incorrect metal temperature, or improper injection speed. Defects can lead to rework, increased scrap rates, and delays. To avoid this, manufacturers must carefully control process variables and maintain molds to ensure high-quality results and optimize production efficiency.

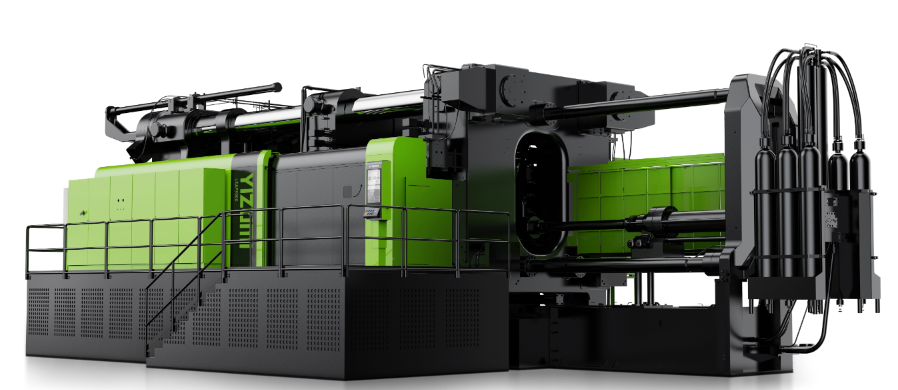

In this article, we'll explore the top four high-pressure die casting defects, their causes, and effective solutions. We'll also highlight how YIZUMI's LEAP Series Ultra-Large Die Casting Machine?addresses these challenges, ensuring superior results for manufacturers.

1. Porosity

Porosity?is one of the most common die casting problems, characterized by small voids or air pockets within the metal. This defect can weaken the structural integrity of the component and affect its surface finish.

Causes of Porosity:

· Trapped Air: During the injection phase, air may become trapped in the molten metal.

· Inadequate Venting: Improper design of venting systems prevents gases from escaping.

· Metal Shrinkage: Rapid cooling causes the material to shrink unevenly, leading to voids.

Solution:

YIZUMI's LEAP Series Ultra-Large Die Casting Machine?is equipped with the Yi-Cast real-time closed-loop injection system, ensuring precise control over the injection speed and pressure. By maintaining consistent parameters, this system minimizes air entrapment and ensures optimal metal flow, significantly reducing porosity defects.

2. Flash

Flash?occurs when excess metal escapes between the die halves, creating a thin layer of material on the edges of the component. While it can often be removed, flash increases post-processing costs and time.

Causes of Flash:

· Excessive Injection Pressure: High pressure forces molten metal out of the die cavity.

· Misaligned Die Halves: Poor alignment allows metal to seep through gaps.

· Worn Die Surfaces: Overused dies may lose their sealing capability.

Solution:

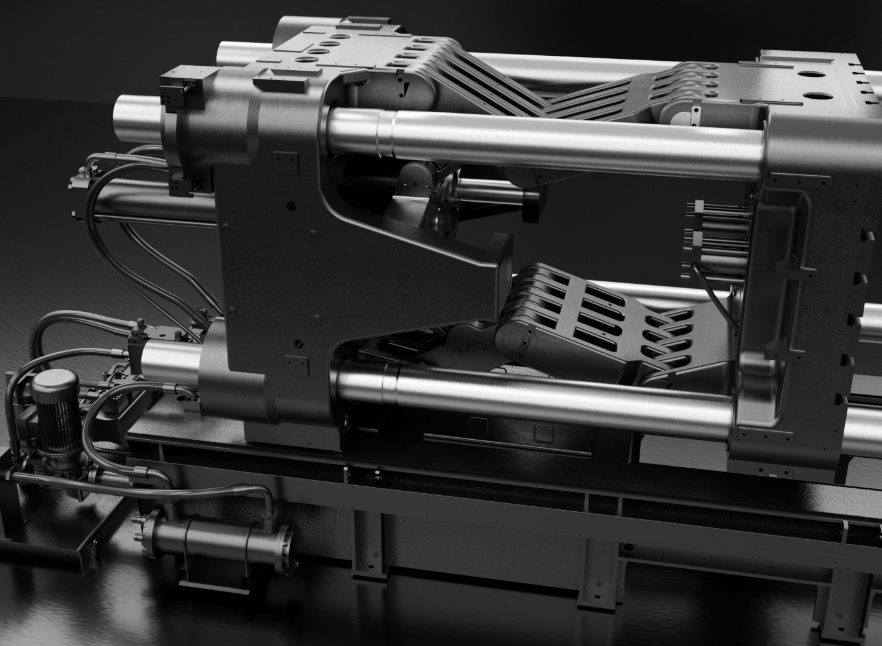

The Intelligent Die Opening/Closing System?in the LEAP Series offers accurate control of die opening and closing positions with repeatability accuracy up to ±1mm. This ensures proper alignment and clamping force, preventing metal leakage. Moreover, automatic clamping force detection helps detect and correct issues in real-time, effectively addressing this common defect.

3. Cold Shut

A cold shut?appears as a visible line or seam on the component where two metal flows meet but fail to fuse completely. This defect weakens the part and can lead to fractures under stress.

Causes of Cold Shut:

· Low Metal Temperature: Inadequate heating leads to improper fusion of molten metal.

· Insufficient Injection Speed: Slow metal flow prevents complete filling of the mold.

· Complex Mold Design: Sharp corners or thin sections in the mold cause irregular metal flow.

Solution:

The Yi-Cast Injection System?in YIZUMI's LEAP Series ensures a controlled and consistent flow of molten metal, even in challenging molds. By maintaining precise temperature and flow dynamics, this advanced system eliminates cold shuts. Additionally, the machine's high-speed and repeatable operations enable manufacturers to handle complex geometries with ease.

4. Surface Defects

Surface defects, such as blisters, roughness, or flow marks, can compromise the aesthetic and functional quality of die-cast parts. These issues are often detected during post-production inspections.

Causes of Surface Defects:

· Improper Cooling: Uneven cooling results in warping or irregular surface textures.

· Contaminated Molten Metal: Impurities in the metal can lead to surface imperfections.

· Inadequate Mold Design: Sharp edges or improper draft angles affect metal flow and cooling.

Solution:

YIZUMI's LEAP Series features a 24-inch ORCA Control System, which offers real-time monitoring and precise control over cooling and injection processes. The intuitive interface allows operators to make quick adjustments, ensuring consistent surface quality. Additionally, the servo + feed technology enhances energy efficiency and prevents overheating, ensuring smooth and flawless surfaces.

How YIZUMI's LEAP Series Stands Out

YIZUMI's LEAP Series Ultra-Large Die Casting Machine?is specifically designed to address the unique challenges of modern die casting processes. It's a tailor-made solution for industries like new energy vehicles that demand large and precise metal components. Here's how it tackles common die casting problems?effectively:

· Energy Efficiency: With up to 40% energy savings, the Yi-Drive Pump Unit?reduces operational costs without compromising performance.

· User-Friendly Operations: The ORCA-HMI system?ensures a seamless and intuitive user experience, allowing operators to optimize production settings easily.

· Precision and Reliability: The Yi-Cast self-learning control system?ensures repeatable results, reducing defects and enhancing productivity.

· Durability: Built for high performance, the LEAP Series guarantees long-term reliability and reduced maintenance costs.

Applications of the LEAP Series

The LEAP Series is perfectly suited for industries requiring high-quality metal components:

· Automotive and New Energy Vehicles: Structural parts, housings, and frames.

· Aerospace: Lightweight yet durable components.

· Industrial Equipment: High-strength machine parts.

By addressing the top four high-pressure die casting defects, the LEAP Series ensures consistent output, meeting the stringent demands of these industries.

Conclusion

Understanding and addressing common high-pressure die casting defects?like porosity, flash, cold shuts, and surface defects is crucial for maintaining quality and efficiency in manufacturing. With YIZUMI's LEAP Series Ultra-Large Die Casting Machine, manufacturers gain access to state-of-the-art technologies that eliminate these issues while enhancing productivity and reducing costs.

By combining advanced systems like Yi-Cast real-time injection control?and ORCA-HMI, YIZUMI redefines what's possible in the die casting process. Whether you're facing challenges with common die casting problems?or looking to optimize your operations, YIZUMI?is your partner in achieving excellence.